Information Technology (IT) Pioneers

Retirees and former employees of Unisys, Lockheed Martin, and their heritage companies

People M-N, Chapter 15

1. Topical Article Contributors

31 writers have contributed 60 technical articles or tidbits complementing the career summaries; see chapter 100, Our Stories.

- Don Mager, Kristen Maloney, Ben Manning, Tony Mannucci, John Markfield, Gene McCarthy, Jack Metzger, Ed Michaud, John Miller, Dr. Tom Misa, Herbert Mitchell, Bengt Monson, Tom Montgomery, Raymond Moon, Roger C. Morris, John Mulhern, Sherm Mullen, Keith Myhre, and Tricia Myhre.

- Ed Nelson, Curt Nelson, Ken Nelson, Les Nelson, John Nemanich, Donald Nesheim, Craig Neudahl, Don Neuman, Ben Nilsson, Ronald Niziolek, Dr. Arthur Norberg, and David Noyes.

2. Career Summaries - M:

2.1 Don Mager, 1955-1985; A tale of two careers.

Although I had electronics training, I lacked experience as an electronics tech, thus my "computer" career started as a draftsman at ERA, in June 1955. A few months later I was promoted to Electronics Tech on the Air Force Tactical Air Control System (TACS) Project. This system, among other interesting features, had automatic system-to-pilot voice response - in 1955! The display subsystem was developed by Skiatron, a New York company and it had many problems. Lyle Gilbertson was named PE (Project Engineer) to resolve the problems. I was tasked to try to make certain that the digital circuitry (mostly vacuum tubes) was more reliable.

A big break occurred for me when in 1959 I was assigned to the AN/USQ-17 project. Soon afterwards the 20A (CP-642A) design was initiated and I had the good fortune of being tasked to assist Bob Burkeholder, a brilliant engineer, on the I/O design. Hy Osofsky was the PE and did the control section design; Glen Kregness did the arithmetic section design and Finley McLeod did the memory. What luck to be involved with such a fantastic crew! The check-out of SN-1 was relatively uneventful, but SN-2 (?) was a different matter. Try as we would, for a couple weeks, we were unable to get it thru the 24 hour endurance run - required for Navy acceptance. So, with the Navy's concurrence the decision was made to ship it to it's destination and hopefully during the long truck ride, the intermittent bug would become solid.

Unfortunately, after installation at NEL, San

Diego, it was found by Field Service personnel to still be intermittent.

And so, one morning about 2 weeks later I showed-up at work, Plant 5,

and Finley McLeod, now the PE, told me they wanted me to go to San Diego

to fix SN-2. I was absolutely flabbergasted! After all, Field Service

had some very highly qualified/experienced people there. People like

Ralph Thompson and Gary Iverson. I had met them pre and during SN-1

and SN-2 checkouts. They were much more qualified than I was. Nevertheless,

within a couple hours I was a tech on an Electra [first time ever on

an airplane], drinking champagne [probably trying to forget what faced

me] on my way to San Diego. I arrived at the NEL site about 6 PM, and

there was Gary sitting at the console stepping thru instructions at

a pace that made my head spin! But, after a few minutes of trying to

understand what was happening, I happened to notice that there seemed

to be something wrong with one of the B [index] register indicators.

Gary assured me that it was nothing of concern - nothing to do with

the real problem. But, probably because I wanted desperately to be able

to tell Mac [Finley] that I'd at least fixed something, I persisted

that we fix that B indicator problem. And, after awhile, probably just

to humor me, they agreed to fix that problem. It took less than an hour

to locate and fix the problem, which was a pinched wire. When we turned

the computer back on it showed-up a new, supposedly unimportant problem

which I again insisted we fix even if not important. Again it didn't

take long to fix the problem and at this point the real problem became

solid! We quickly tracked it down to a bad PC board (loose getter in

a transistor) and we were all confident the problem was solved. By 10

PM Dick Gehring [Field Service VP] was on site and a decision was made

to start the endurance run at midnight. I went back to the motel and

there sitting at the bar was Ralph Thompson. He said, "St. Paul told

us they were sending someone out to help us fix the problem. We assumed

it would be Glen [Kregness] or Hy [Osofsky] and then you walked in the

door." One of the best backhanded compliments I've ever received.

During the next few years I was involved in several projects

including the 1218 development and the UDT (Univac Digital Trainer).

About 1963, I proposed a design for an I/O console which would dramatically

improve the performance over the Flexo-writer and Ferranti reader based

system. The 1232/1532 I/O console was my first real role as a PE and

I also did the logic design. I also did the logic redesign of a special

1218, for the Air Force, such that it would, for security reasons, run

in an "interlaced mode". In this mode it would run every 2nd, 4th or

8th instruction {Editor note: 1218M on geneology charts}. Memory lock-out was actually a better way to provide

similar security. Another special 1218 based computer was the 1224 for

NSA. I was PE and did the control section and Leroy Olson did the I/O

design. This computer had some really weird algorithms and was likely

one of NSA's first computers specially designed to surreptitiously monitor

communications - {editor's note: Ernie Lantto became PE for minor

upgrades before production}.

The 1230 computer was the result of an engineering proposal that Glen

K. and I did, in 1964, for a computer for NASA Apollo telecommunications.

When Univac won the contract, Red Phillips, our new boss at Plant 5,

made me PE. Bob Oulicky designed the I/O, Glen Kregness designed the

arithmetic section and I designed the control section. This became the

CP-855/UYK, for political reasons called the Modified CP-642B. Although

it used the same logic family PC cards as the 20B and the same cabinet, it's

memory was twice as fast at 2 usec and it was capable of operating in

an instruction/operand overlap mode, thus achieving almost 4 times performance

of the 20B. {Editor's note: By organizing the memory into banks with

two or three or four sets of addressing and data wiring, processor

logic could fetch the next instruction while fetching the current

operand.} It was also capable of having up to 262K of total memory

with an additional external cabinet. The external memory presented a

difficult wire count problem which resulted in my first computer related

patent - the idea of sending logic data bi-directionally over the same

wires {read and write data lines}, reducing wire count by 50%. Today that concept is ubiquitous.

One day, just before start of checkout, as I was preparing to

go on a one day marketing support trip, Red asked, “How are things

going?”. I replied, “Good, but it sure would help if I could

park in the ‘professionals’ parking lot, close by plant.”

When I got back from the trip, there on my desk was a yellow parking

sticker, a promotion to engineer and our assigned parking spot right

next to the entrance to Plant 3! Tom Herschbach, VP Manufacturing, had

the spot on the other side of the door. Red sure knew how to wind/tighten

a guy's spring!

It took us 9 months to design, build and checkout the first 1230 unit.

The pressure of this project was so great on me that I not only lost

a lot of weight (starting at 135 lbs, not much to spare) but also, I

nearly went "over the edge". After watching it loaded onto a semi for

shipment to Goddard, on a sunny July afternoon in 1965, I got in my

car, drove around the corner from Plant 3 onto Prior Ave, parked the

car and just sat there for 20-30 min. I was unable to drive, emotionally

overwhelmed. It felt like a 1,000 lbs had been lifted off my back. I

vowed, to myself, I would never again get that involved in a project

- and I never did. I was suffering from PCS (post checkout syndrome)

a term I started using a few years later to describe this situation

to logic design engineers. Doing logic design is a totally cerebral

effort with ever increasing hectic pressure and long hours, culminating

in checkout completion/shipment - an abrupt end. Like running into a

brick wall! It would be easy to write an entire chapter on this subject.

A “shrink” could probably write a book or two!

The CP-890/UYK navigation computer for the Poseidon nuclear submarines

was initially bid as a standard AN/UYK-7. However, there was a requirement

that it go down the submarine hatch without disassembly. Since the AN/UYK-7

did not meet that requirement, Sperry Systems Management (SSM) rejected

the proposal. Consequently, I was asked to prepare a Plant 5 engineering

proposal. The result was a hexagon shaped computer which would go down

the hatch fully assembled – the CP-890/UYK. We were awarded the

contract and Red asked me to be PE. I said OK, if during that time I

didn’t have to make marketing support trips - although I must

confess trips with guys like Bill Rock were always interesting. Red

said, “It’s a deal”, and we shook hands on it. The

PE responsibility on this project was broader than usual. The contract

required that all the performing organizations’ personnel report

to the PE, including Manufacturing, Quality, Reliability and Field Service.

The CP-890 was based on the 1230 computer. It had a 1.8 usec, 3 wire core

memory and was proposed with a mated-film control memory. The mated-film

control memory, although the best solution at the time, was power hungry

and quite large. So, when I became aware that an IC with 16 bits had

been developed and would soon be available, I immediately requested

approval from the SSM and the Navy to use the 16 bit IC in place of

the mated-film. They approved. Unfortunately, DSD management didn’t.

I was told not to use it because it was too risky - it wouldn’t

be as reliable as our P/N 7901000/1001 DTL IC’s. Mind boggling when one considers

that today’s IC’s have more than a million times that much

memory! I was thoroughly frustrated/disgusted until one day Red asked

me to go on a one-day marketing trip. I reminded him of our deal, but

I would be willing to go if he would get management approval to use

the 16 bit memory cell. Without hesitation he replied, “It’s

a deal” and we shook on it. A couple days later, when I got back,

there on my desk was a letter approving use of the 16 bit IC. I now

was confident that we’d be able to fit everything into the allowable

space. One of the unique challenges was the requirement to be able to

withstand major power interruptions. At acceptance, the customer was

amazed that we could flip the power switch off and on and the program

never lost it’s way! The key members of the excellent design team

were: Glen Kregness, Dick Erdrich, Neil Macrorie, Bob Wyland, John Bruder,

and Jim Warwick. I did part of the control section design. The Poseidon

Navy people were extremely pleased with the CP-890 because of it’s

outstanding performance and reliability (and it fit down the hatch.)

Times were a little slow in 1969, and so we were given the job

of designing a 2 wire, core mass memory for Sperry Roseville and of

course we needed a memory exerciser. It occurred to me that memory exercisers,

like computers, always had many so-called “logic bugs” when

first turned-on, but in reality these were implementation errors –

very few were actual logic errors. Typical errors were documentation

errors, incorrect pin assignments, duplication of logic elements, PC

routing errors, PC assembly errors, wiring errors, etc., etc. So, I

challenged Paul Kruelle, who was designing the memory exerciser, to

do a design and check for errors to such a degree that when the exerciser

is first plugged-in it would immediately run – error free. He

took the challenge eagerly. Some time later, when he turned it on, there

was one problem – the RUN switch was active in the down position

instead of the up position. I asked Paul, “How come you screwed-up?” He said, “The V-drawing was wrong!” Based on that experiment,

we started a campaign to convince everyone in the department that it

was possible to have very close to 100% perfect logic designs. What

is required is checking, checking, and rechecking to eliminate implementation

errors! We found that to get people to do that, it’s necessary

to convince them that all that checking is cost effective. So, we started

a departmental campaign. Our slogan was: Accuracy Pays – which

we put on give-away trinkets such as magnifying lenses, pens etc. I

bring all this up because it was a key factor in the success of the

next project – the S-3A computer, also the AN/UYK-43, AN/UYK-44

and several others.

Things were going just fine, in the fall of 1969, when Red called

and asked if I would meet him at The Criterion for lunch. When I got

there, there also were Bill Gieger and Don Vizanko. Now what?? After

a martini, they let it out – they wanted me to be the new S-3A

Project PE. This was the AN/AYK-10 computer being designed for the S-3A

anti-submarine airplane. Their idea did not enthuse me. The project

did not have a good reputation. About a month earlier, Red had asked

me to look into what could be done to get the S-3A processor performance

up to requirement. Because Glen K. was so capable and respected by all

the engineers, I asked him to go over and talk with the guys. He quickly

concluded that they could solve the problem by using a few of the higher

power type TTL IC’s in key spots in the logic. We passed this

on to Red. The suggestion was not utilized because Engineering knew

and Program Management confirmed that the contract did not allow those

type of IC’s.

The S-3A project managers were not thrilled to see a new PE.

The first thing I did was eliminate a level of management, a few extraneous

jobs/positions and daily “action item review” meetings with

the managers. At the first meeting with the managers, I assured them

I was on their side and we would win, but we needed the best help that

we could possibly get, from all the other departments. To get that best

help we need a “winner” image. I made it clear that anyone

who bad-mouths the project will immediately be let go from the project.

The project had major problems: The processor was too slow; The computer

was 35 lbs over weight; Design was behind schedule and the project was

over budget.

Solving the processor performance problem was easy. With the

concurrence of the logic engineers, I informed Program Management [Dan

Brophy] that we would be using some higher power IC’s, told them

what the performance would be and please get the contract changed. Within

a week or so, the customer (Lockheed) had agreed. One problem down!

Eliminating 35 lbs was tougher. Paul Richardson, was the customer required

weight analyst - as in airplane design. He did a great job of helping

get every possible ounce out of the design. Lockheed people, being airplane

builders, riveted everything and we, DSD, tended to weld. They kept

suggesting we go to a riveted cabinet which would save considerable

weight. Our engineers were resisting because of possible RFI leakage

concerns. I finally convinced the engineers that it was a political

decision. It makes sense to go to a riveted cabinet. At least the airplane

will get off the carrier deck and if there is RFI leakage it’s

the customer’s problem – we did what he wanted.

The biggest challenges were the schedule and budget problems,

which were very related. The design employed 12 layer PC boards. Correcting

a logic problem on an inside layer was virtually impossible. So the

project plan was to breadboard the entire system using wire wrap connections

between the IC’s. Based on Paul Kruelle’s “error free”

effort, it was clear to me that the bread boarding would likely increase

the number of implementation errors, because there were so many more

steps. Furthermore, with the project expenditures running at almost

$100K per week, the bread boarding approach would cost well over $1M

and add several months to the schedule. I was able to convince the managers

and engineers: Let’s instead spend some of that $1M plus on checking,

checking, and rechecking. It wasn’t long before the logic guys

had bets, amongst themselves, as to who would have the fewest errors!

At that point, success was assured. Although the “accuracy”

effort focused on the logic area, it involved all areas, including build.

Checkout, on this complex multi-processor system, was completed in a

matter of a few weeks. A great accomplishment! The key managers were “Chuck”

Mattson, Gary Bosworth, Larry Lesko, and “Swede” Berg. The

key lead logic designers were Tom Petschauer, Lew Carlson, and Gerry

Shaw. The first unit, a welded version, was accepted by Lockheed in

January, 1971 - on schedule. The first riveted version came in a short

time later at 385 lbs.- exactly on target!

The role of being the PE on computer design projects finally

came to an end. The S-3A was the last computer design for which I was

the PE. A couple years later I was given responsibility for all computer

design/development activity. I was Director of Computer Development

for about 7 years – a record. During that time the department

did numerous computer designs, the most significant of which were the

MPC-1616, the Reconfigurable Module Family (RMF) series, AN/AYK-15,

AN/UYK-20, AN/UYK-23, AN/UYK-43, and AN/UYK-44. The UYK-43 and –44

both utilized an MSI technology shared with Sperry Roseville. But, there

was a huge difference in implementation technique. They bread boarded

their designs. We opted for “Accuracy Pays” and thus had

a much shorter schedule and lower development cost – which upper

management never did seem to fully understand/appreciate.

My final year at Sperry was much different than the first 29

years. Although for the first time I had nothing to do with computer

design, it was very interesting! I roamed around the country looking

for business opportunities for Sperry Defense Systems. One of the opportunities

I came across was some interesting “laser scanning” technology

3M had partially developed, but for which they didn’t have a good

application. Unfortunately (fortunately?) it didn’t seem applicable

to Sperry’s defense business interests either.

Thus began my second career. In 1985, after 30 years, I left

Sperry and co-founded, with a fellow from 3M, a start-up company –

Printware. I provided most of the seed money thus became the President

and CEO. We developed a computer-to-plate laser imaging machine and

soon, with Deluxe Check as our key customer, 50% of the checks in the

US were being printed using our machines and using our special plate

material. Printware eventually traded on the NASDAQ exchange, but was

subsequently taken private. In 1988 I received an “Entrepreneur

of The Year” award from MN Gov. Rudy Perpich. About the only thing

that was good for was it legitimized putting “entrepreneur”

on my business card.

ERA/Remington Rand/Univac/Sperry – What a great company

(people) to have worked with!

![]() Don V. Mager

Don V. Mager

2.2 Ben Manning, 1969 - 2006

Ben joined the Univac International Research &

Development Center (IRDC), London, UK in mid-1969, where he maintained &

enhanced the NELIAC compiler for a Univac 494 computer. He also built

a syntax analyzer to reformat compiler source rather than manually recode

and later worked on a real-time scheduler for the STARS Airline Seat

Reservation System. In mid-1970 Ben joined Univac UK, in London as the

lead on the development of a communications front-end for a Univac 418

III computer at J. Lucas Electrical, Birmingham, UK.

In 1972 Ben joined Sperry Univac World Wide Marketing, in Blue

Bell, PA, to work on the Law Enforcement Application Package (LEAP).

This project, under Dr. Hans Hermans, developed the LEAP Programming

Language (LPL) interpretive compiler for the Univac 418 III computer.

LPL was similar to the modern JAVA language in that instructions were

executed interpretively to provide a secure environment. Much of this

work was performed at the Pennsylvania State Police Center, Hershey,

PA, and on assignment at the Minnesota State Police in St Paul, MN in

the summer of 1974.

In early 1975 Ben joined Sperry Univac, Defense Systems Division

at the FAA Tech Center (then known as the National Avionics Facilities

Experimental Center (NAFEC) in Pomona, NJ). At the Tech Center he initially

maintained support software for the IOP & CPM processors and later

developed a Disk-resident Batch Operating System based on Djikstra’s ‘THE’

system.

In January 1977 he moved to Sperry, Defense Systems, St. Paul,

MN, in the International Systems Engineering group under Denny Stanga.

In May 1977 he flew to the Telefunken site in Ulm, Germany, to integrate

an ATC demonstration that was presented in June 1977 at the Paris Air

Show, France.

In 1978 Ben, Leo Slechta, and Wilson Wen were the principal architects

for the TAOC-85 system design. They built & demonstrated the High

Speed Search Unit (HSSU) associative processor development, which resulted

in multiple US Patent awards – Ben has two of them. One of Leo’s

patents from this development was the Variable Cycle Time Clock, which

he later used on the AN/UYK-44 development.

Between 1979 and 1982 Leo and Ben (and later just Ben) defined,

built, and demonstrated the System Control Unit (SCU), a hardware executive

kernel based on the AN/UYK-502. The 1982 demonstration of SCU performance

was accomplished through a port of the Trident Carry-on Reduction System

(TCRS) to OS-16; the SDEX-20 kernel was removed entirely, with OS-16

running on the bare SCU-based machine. The benchmark showed a 100x performance

improvement in message handling on the network.

In 1982 and 1983 Ben worked with Tom Wolff, Larry Anderson, Don

Bennett, and the technology team on the VHSIC Sub-Micron project with

TRW in Los Angeles, CA. On March 1st, 1983, his 1st HSSU patent was

awarded.

Between 1984 and 1987 Ben lead fault-tolerant computing architecture

studies for what was the Naval Ocean Systems Center (NOSC), in San Diego,

CA. The initial study was for a Fault-Tolerant AN/UYK-44 based on the

MIT Draper Labs FTP System; Draper Labs were a subcontractor on the

study. The second study was for a Fault-Tolerant PI-Bus approach; the

study showed that the Pi-Bus did not support fault-tolerance well. In

March, 1985, his 2nd HSSU patent was awarded (this was the system level

patent).

In 1987 and 1988 Ben spent some time in Business Development

doing Technology Marketing, mainly in support of the MULTITUDE Parallel

Processing system developed by Steve Murphy, Larry Anderson, Don Bennett,

and Brian Larson. In 1990 and 1991 he worked IR&D, supporting Vince

Splett on the Passive Direction Finder (PDF) Demo and its follow-on,

the EW Workstation.

In 1992 Ben started his IR&D developments in support of Maritime

Surveillance programs. Initially, he worked with employees from Winnipeg,

Canada, on their ADMOS Demo for the New Shipboard Aircraft helicopter

system. This evolved in 1993 into the P-3C CHRD demo system, resulting

in the P-3 fuselage mockup demo lab. The equipment in the P-3C CHRD

lab supported both the RAAF Proposal demonstrations in Canberra, Australia,

and the March 1994 Navy League demo in support of AIP proposal.

After the AIP Program win, Ben performed as lead on the VDC Firmware

development from 1994 to 1996.

Following the AIP FQT in 1996, Ben moved back to IR&D to

define the S-3B X-Windows system architecture. This effort was once

again in collaboration with our colleagues in Winnipeg and continued

thru 1997.

In 1998 Ben took the lead on the Java for Tactical Computing

(JTaC) IR&D started by Bob Shepard and Steve Sohn. Working with

Steve Sohn he helped provide an ATC track feed from MSP airport to project

within Plant 8. During this time Ben also assumed the lead of the LMTS

COTS Focus Team and participated as the LMTS representative on the NE&SS

COTS Working Group and later for the EPI Center Commercial Engineering

Practices (CEP) Sub-council.

Ben was the LMTS lead for the LM-21 COTS Best Practice transfer, for

which we were a source site. Based on the information uncovered during

the best practice transfer he worked with the COTS Focus Team to develop

and publish the LMTS COTS Technical Management process (PREN0500), which

recently became the MS2 COTS common process.

Ben work as a member of the team that developed the Strategic Sourcing

process (PRPR0100), which has metamorphosed in to the current LMTS Sourcing

process. Prior to transferring from TechOps into Operations to run the

Strategic Sourcing program Ben was a significant contributor to the

draft Engineering CMMI compliant process (PREN1000).

Following the transfer to Operations, Ben helped define the Global

Supply Chain Management (GSCM) process. He acted as Manager, Strategic

Technologies, in the Production Operations organization for two and

a half years.

Ben moved back into TechOps to manage the Anti-Tamper (AT) portion of

the MMA program, which we promptly lost shortly after his transfer (no

connection here). After the MMA loss Ben took on the lead of the Anti-Tamper

IR&D program, working with other LM sites (Orlando & Moorestown),

the AT customer and DoD labs, such as Sandia, to help bring the AT culture

into LMTS.

In late 2004 Ben took on the role of Systems Engineering Functional

Manager for the RCI Systems Engineering personnel, a position which

he held until retiring in June, 2006. He feels that the functional manager

role is key to LMTS at the current time because of the need to maintain

our high quality workforce despite the demographic shifts that are underway.

![]()

2.3 Gene McCarthy, 1960-

I was born and raised in Bayonne, NJ - attended

High School in Staten Island, NY. I enrolled in the NY Maritime College

majoring in Marine Engineering. After two years I realized that the

Merchant Marine was not in my future. I was hired at Curtiss Wright

as an assistant engineer, while I was applying to St. Peter’s

College. I received an Acceptance Letter from St. Peter’s and

a Draft Notice on the same day. After serving four years in the Air

Force as a Search Radar Repairman, I joined Remington Rand Univac on

September 12, 1960. My first project was Field Engineering on the Athena

Computer.

After assignments at Bell Telephone Laboratories, at Whippany,

NJ, the Athena Test Facility in St. Paul and the Titan I ICBM site at

Buckley Field, CO, the program was cancelled because the Titan II Program

was put into service.

I joined the ANEW Program in St. Paul as a Programmer. The ANEW project

was sent to the Naval Air Development Center, Warminster, PA in 1965.

The ANEW Project was the first implementation of computerizing the Lockheed

P-3 Anti Submarine Warfare aircraft. I worked on the P-3 Laboratory

Simulation Program and Advanced Signal Processing programs.

As the USN was phasing in new airborne ASW aircraft into the

fleet, the Canadian Department of National Defence (DND) decided that

as a NATO member, they also would need to develop a Long Range Patrol

ASW, aircraft with state-of-the-art Systems Capability. They had the

choice of buying what the USN was developing, from the USN or Developing

their own ASW aircraft and systems. Of course they chose to develop

their own.

During early 1972, the Canadian DND asking for Concept Definition

Phase proposals to multi engine aircraft Companies. DND was asking for

an ASW and Troop Carrying capabilities in one configuration. Boeing,

McDonnell Douglas and Lockheed CALAC responded. MD responded by proposing

their DC-10, Boeing their 707 and Lockheed their P-3C. Sperry Univac

DSD Proposed to MD as well as Lockheed. Boeing was doing their own thing.

The DND was enthralled with the MD DC-10; but the DND required more

than two for the available Program dollars. If MD had not stopped building

DC-8s, they would have been the Winner. The Avionics System they and

Sperry Univac proposed was well received.

The final Request for Tender went out to Boeing and Lockheed.

Stan Foote, Director International Marketing asked his Marketing Manager,

Gary Holthusen, to bring in a sales person with P-3 ASW experience for

assignment to the Canadian Long Range Patrol Aircraft (LRPA) Program.

I was asked to move from NADC to Eagan to take the position, which I

did.

DSD already had a team working on the proposal with Lockheed.

Therefore my job was to get the lay of the land and talk to the DND

Air Force people managing the Program. Canadian AF Major Ziglegansberger

was the technical leader of the program and our expert in ASW signal

processing. I also met the General, Program Director, and the Colonel,

Program Manager and Contracts Director as well as the folks who would

enforce the Political requirements which are known as Industrial Benefits.

After meeting with several City Managers, we selected Winnipeg

to City for our Industrial Benefits because of its high tech work force,

prominent National Politicians and of course, Winnipeg’s close

proximity to Eagan. Overall, it was insinuated to me that Boeing could

probably use our help as well as Lockheed. The CAF Program team seemed

to want a jet plane rather than the propeller plane that the Americans

are in love with. I kept thinking that there would be one winner with

two proposers. That amounts to a 50% chance of winning. That would be

considered a great chance in some leagues; but not this one. I therefore

made plans to visit Boeing. I put together the team with the proper

skills and the presentation materials I needed. I then made the argument

with my managers to allow me to visit Boeing and they agreed, providing

I pitched the S-3 AYK-10 computer. I made a call to the Boeing Program

Manager and he agreed to host a meeting where he would have the appropriate

people in the meeting. I knew they preferred a distributed system, so

I also had Paul Williams prepared to present the UYK-20.

The only statement the Program Manager managed during or after

the AYK-1832 presentation was no thanks. I said I had one more presentation

and he agreed. Paul Williams gave the UYK-20 pitch, which did raise

a few eyebrows and a lot of interest. Then they wanted to know why I

was presenting a shipboard computer for an airborne application. I said

that I went on the basis that the aircraft was a 707 and the vibrations

and the ambient parameters would be benign. The program manager shot

back, “how long would the UYK 20 run if a 30 in. hole was suddenly

blown in the fuselage, at 30 thousand feet”? I answered that no

one on the plane would know, or care, if that calamity indeed happened.

The Program Manager thought for a few seconds and then said, I guess

you’re right about that. We went on to bid a six computer system

and a high percentage of the Application Software, including the two

Univac 1108 based ground systems, which we also bid. The overall proposed

dollars were about the same regardless of which prime won. Sleep comes

a lot easier with a 100 percent chance of winning.

Lockheed did go on to win the 18 CP-140 aircraft program and

Ground Systems based on price and not the proximity of the US Navy.

We did open an assembly plant west of the Winnipeg airport with Gerry

Smith and Glenn Johnson, selected by Bob Faust, to manage the plant.

Many cables and electronic boards were assembled and installed into

the AYK-10 computer in Winnipeg for the CP-140 program.

As I was meeting with the CP-140 program folks in the DND Headquarters

building in Ottawa, I was asked by Gary Holthusen to visit a Lt. Cmdr.

Carruthers of the Canadian Navy, who had some questions concerning the

UYK-20 computer. I called Cdr. Carruthers and made an appointment to

meet with him. I called the Commander from the lobby and he came down

to meet me. He also took the opportunity to brief me on the makeup of

the Navy as well as the organization he was part of, Directorate of

Maritime Combat Systems. Jim Carruthers worked for DMCS-7, Systems Engineering,

led by CDR. John Matthewson. DMCS-7 was responsible for all the System

Interfaces that go onto a given ship class. DMCS-1 thru 6 are assigned

as Navigation systems, Radar systems, Communication systems, Sonar systems,

Gun systems, Machinery Control etc. A Navy Captain is Director of Maritime

Combat Systems.

Cdr Carruthers was tasked with developing a mini Command and

Control system, known as ADLIPS, for the newest destroyer class ships,

the DDH-280 Class. New computers and software were required and Cdr.

Carruthers was interested in learning about the US Navy UYK-20 for the

Computer system. He had previously investigated all the Competition’s

computer offerings but I was the first Sperry Univac marketing person

he had the chance to talk to. I told him about the UYK-20 and had several

more meetings with Jim and interested military and engineering personnel

from the other sections of the DCMS. At one meeting with about 30 Canadian

DMCS engineers, I had Mel DeBlauw answering there questions for about

two hours concerning just about every technical nuance imaginable and

Mel answering the questions from his memory to their satisfaction. One

more question was asked about some minute detail on packaging and Mel

held his chin with his fingers and really stared with a deep frown

for a couple of minutes then said “I just don’t have that detail

on the tip of my tongue”. The audience roared and Jim Carruthers

and John Mathewson were proud of the knowledge base of Sperry Univac.

Jim ended up ordering 18 UYK-20 computers for the ADLIPS program.

The Software was developed by Litton Systems Canada, the ADLIPS Contractor.

After Buy-off at our Clear Water Plant, DMCS had them consigned to a

storage crib in Clearwater, FL until the program was ready for them.

In the meantime, the US Navy approved a development contract

to double the amount of the UYK-20 Memory. I told Jim that we had the

Development contract and after talking to his colleges and the ADLIPS

program people, he called me to Ottawa to meet with him and his DMCS

superiors, Cdr Matthewson and the Captain. Since the new expanded memory

would go into the same slots as the previous memory, Jim asked if Sperry

Univac would buy back the unused memory of the computers in storage

and insert the new expanded memory and they would pay the difference

in price. I said it sounded reasonable to me but I would have to check

our contracts department.

It sounded good to my management, Tom Knops and John Spearing,

however, Don Blattie, our Contracts Manager said the memories in storage

were officially bought and accepted by the Canadian Navy and would therefore

be considered as used equipment by our US Navy contract. Our US Navy

contract calls for exclusively new equipment. We could not put them

into the next computers coming down the line. I felt as though I was

in a vise until I asked Don Blattie about the Foreign Navies that were

buying UYK-20 Computers. Do they also require exclusively new equipments

in there contracts? At least one did not. The exchange was made and

the Canadians bought the first 16 Expanded Memory UYK-20 computers that

our company sold.

The CPF program is discussed with the “CPF Anatomy of a

WIN”. The Canadian Navy went on to build 8 ships of a planned

16 ships. An abstract of Jim Carruther’s SHINPADS paper printed

in the April, 1979 Naval Engineers Journal may be a useful definition

of SHINPADS.

My last program of importance was the P-3 AIP program. This was

the first set of a complete modernization of the P-3 Fleet of ASW aircraft.

I was also the first total competitive Aircraft and System Upgrade Prime

contract that we proposed and won. Our competition was LM Marietta.

It was a great win. The initial contract was for $29M for six aircraft.

The remaining 240 aircraft upgrades followed.

My last success was to happily retire in 1996 after 36 satisfying

years. ![]()

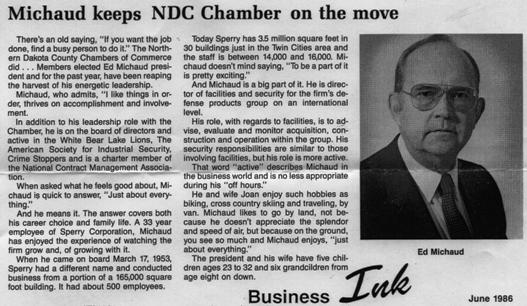

2.4 Ed Michaud, 1953-1986.

March 1953 to December 1986

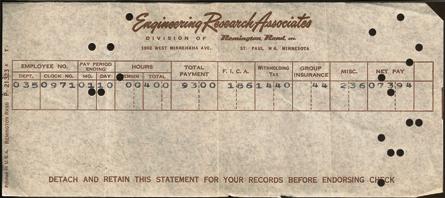

I began my career with Engineering Research and Associates, Division

of Remington Rand. My first job assignment was on Project 1112 which

was titled "Construction of ERA 1103 Computer Systems. The Project Supervisor

was F. P. (Frank) Mullaney and the Project Engineer was R. P. (Bob) Murnane.

The total employment of ERA in St. Paul was about 600. From 1953 through

1964, I worked in a varying number of administrative positions with

increasing responsibility in Engineering, Product Design and Manufacturing

and was ultimately promoted to Manager, Contract Services and Spare

Parts in the Contracts Administration Group.

In 1970, I was named Group Manager of General Services in Industrial

Relations. I replaced Mr. Knight Pryor who had retired. That position

was in charge of all physical facilities and associated services for

the Defense Systems Div. This included all tenant functions including

leasing, building design, construction, maintenance, industrial and

government security, office services, communications, transportation

and energy/environmental management.

retired. That position

was in charge of all physical facilities and associated services for

the Defense Systems Div. This included all tenant functions including

leasing, building design, construction, maintenance, industrial and

government security, office services, communications, transportation

and energy/environmental management.

In 1977 my position was expanded to include responsibility for

Defense Systems Facilities in Clearwater, FL; Salt Lake City, UT; and

Winnipeg, Canada. With this added responsibilities, came a promotion

to director.

In the fall of 1984, the Sperry Corporation created the Defense

Systems Group under the leadership of R. L. (Dick) Seaberg. It included

all Military and Defense business and related facilities in the Gyro,

Flight Systems, and Marine Divisions - world wide. As a result of this

reorganization, I was promoted to the position of Executive Director,

Facilities and Security - Defense Products Group. The duties of my position

required extensive contact with State and local government and business

entities involving property and community relations. It was a position

that was very action oriented and involved in many varied aspects. I

can truly say that I enjoyed most every day.

I retired from this position in December, 1986. ![]()

2.5 Don Moe, 1957-

This is Don Moe’s profile - he worked for

several Lockheed Martin predecessors experiencing many diverse career

assignments while in the computer application field. These experiences

started at Remington Rand in the 1957 and were enjoyable, including

the positive experience of working both in the military and commercial

divisions of the company. This career acquainted him with many people

while giving him knowledge of different applications, events, and customers.

Don Moe majored in college in Mathematics and Business Administration.

After college, he joined Remington Rand, later renamed Remington Rand

Univac, then Univac, Sperry, then Sperry Univac, and Unisys. At these

companies he worked on computer engineering projects in both the Defense

and Commercial divisions. Initially, he was a statistician/mathematician

where he worked on various mathematical studies for the company. While

in this position he learned to program from a co-worker; and he went

on to program several mathematical equations he was using in his work

on the computer. He became fascinated by programming and transferred

into a programming group. Don was fortunate to be involved in the infancy

of the computer age and to work on “state of the science”

projects in the technical engineering field for customers like: National

Aeronautics and Space Administration (NASA), U.S. Navy, and the U.S.

Air Force. In the company’s Defense Division his work consisted

of the design and development of scientific computer programs used in

the guidance of missiles Simulation (SIM), Computerized Training for

astronauts (Simulation Checkout and Training System (SCATS), statistical

analysis and reduction of satellite telemetry data (Gemini Launch Data

System-GLDS), simulation programs and other engineering applications.

He worked on the Department of Defense (DOD) classified missile guidance

programs involving both Satellite Intercept (THOR-ABLE, DELTA) and Intercontinental

Ballistic Missile (ICBM) Launches (TITAN). These programs were involved

in the early exploration of space and Soviet intelligence gathering

via spy satellites launched from Vandenberg AFB in California and Cape

Canaveral in Florida. There were also programs involved in Satellite

interception launched from Johnston Island in the Pacific. These programs

involved working with major DOD contractors like Lockheed and Government

agencies like NASA. He personally developed numerous engineering/scientific

programs; logic simulator, reliability analysis, missile guidance simulation,

real-time telemetry, training simulators and engineering beam stress

analysis. In the Domestic Division he worked on application programs

in the education field (Chicago Board of Education), application programs

for large scale computers, automated engineering design programs used

to logically design (via Boolean equations) new computer architectures,

and test programs to verify the functional operation of computers and

their peripherals.

After several years working as a computer software

engineer in the technical field, he advanced to supervisory and management

positions at age 29, where he was involved with the design, development

and support of computer systems. While in Engineering he assumed project

management roles on large hardware and software projects. In engineering

management, he managed 30 professional engineers with the accountability

to develop hardware and software programs in support of computer product

integration and acceptance. These groups included engineering, system

engineering, support engineering, software development (both in application,

systems programming and test programming). He provided leadership to

professionals (35 engineers) performing systems analysis in support

of system definition and design to achieve stated objectives. This group

included system analysts, system engineers in the design, development

and integration of new DOD systems. He was accountable for a group of

professionals (30 engineers and programmers) responsible for developing

software used in the checkout of major computer systems. This test engineering

and simulation software experience included the development of both

simulation and test software for both Defense and Commercial hardware

configurations. He also helped structural engineering organizations

(10-60 professionals) to perform specific charters. This involved manpower

planning and establishing working relationships between customers and

internal company organizations.

He entered the Program Manager organization where he was responsible

for the management of all the software development programs associated

with the Navy business area. Some of the major programs were Technical

and Management Services (TEAMS), Tactical Flag Command Center (TFCC),

Dynamic Simulation Subsystem (DSS), Automatic Direction Finding System

(ADF), and Improved Tactical Air Operations Center (ITAOC). He was the

Program Manager for a 50 million dollar Navy project contract for technical

engineering and management support. The company helped him to demonstrate

management ability on major computer development contracts both from

an administrative and technical viewpoint. One of the most recent was

the Program Manager responsibility for a multi million government (Navy)

contract. In program management, he had responsibility for various projects

and programs. These projects helped develop his capabilities, and he

used special skills in customer interfacing, business development, teaming

negotiations, proposal strategy/negotiations, system analysis, engineering

management and program management.

At Unisys and its predecessors, he traveled over two million miles.

He consulted for several other computer companies

after he left Unisys, such as Atlantic Research Corp (ARC), Computer

Science Corp (CSC), Marktech, Smart Solutions, Knowledge Management

Inc. (KMI). His consulting experience included the following: Therapeutic

Immunology, Inc. (TII), a medical company, where he coordinated requirements

(project management) between Medical Doctors, PhDs, and management personnel.

At KMI he worked on a users manual for the software development company

that designed and developed a state of the art system utilizing artificial

intelligence technology/knowledge based systems. At Marktech Group,

Inc., he worked on new business Development for a small medical computer

company, working with major primes and other small companies to sell

Marktech's expertise and develop teaming agreements and project management

functions. At Smart Solutions, Inc., he also worked on new business

development for a computer company involved in developing knowledge-based

systems utilizing the technologies of multimedia, and information dissemination.

At ARC/CSC, he has primary project responsibility for the development

of the technical and cost proposals for a large ($50+M) proposal. A

great journey with no regrets!

On a plane ride to Texas with Dick Lachenmeyer, I met Vice President

Hubert Humphrey.

![]()

2.6 Joyce Mortison, 1961-1988

I am a Unisys/Lockheed retiree that worked in the computer technology field for 27 years. My educational background is: BA Economics and Mathematics, University of Cincinnati

MBA University of St. Thomas, St. Paul, MN

My first job was at Procter and Gamble, doing market research and

multiple regression analysis. From there, I had the great fortune to

be on the ground floor of both the emerging computer world plus space

exploration. I worked for GE/NASA on the Saturn V, working with Von

Braun's staff and other German scientists. I found contributing to the

US space program was awesome and very rewarding.

My next opportunity was being a Research Fellow on the Faculty of the

Univ. of Minnesota. I did statistical analysis on 150,000 children for

a US Congressional Subcommittee that brought funding for the School

Lunch Program, Low Income Health Clinics and the Maternity and Child

Health Programs.

Next I worked at Univac in St. Paul. My research projects included software engineering, structured design methodologies and the software life cycle support tools. I designed the PROVAC (Process Visibility and Control System) that allowed management visibility into the software development life cycle. I made presentations at Gull Lake, COMPCON 77, and at the 3rd National Security Industrial Assoc Software Conference. I served nationally on the NSIA Software Quality, Reliability and Assurance Committee as well as the IEEE Software Engineering Technical Committee.

My next job adventure was under the Jimmy Carter energy initiatives. Our team won the proposal to create the Solar Energy Center in Golden, CO along with four Regional Centers. We created Energy Information Computer Networks into all 50 states plus Puerto Rico and the Virgin Islands. I was the Information Technology Manager for the Mid-American Solar Energy Complex in Eagan, MN.

My next job adventure was to return to Unisys where I was a Software Engineering Resource Manager handling Underseas Resource Projects. This assignment was in the Systems Engineering Division under Dave Kolling.

Some of the changes that I have seen in the workplace is that women are advancing in management opportunities and better equal pay situations, comparing the 1980's to the 1960's. So things are getting better and more equalized for women as time goes on!

2.7 Lyle Mozak, 1969-1987

What an incredible web site.... awesome ! I worked for Univac - Sperry for 17.5 yrs.. from 1969 - 1987. Started as a hardware technician, then systems, then pre-sales, sales then management. Sold first Mapper system in Canada here in Edmonton, Alberta to automotive parts distributor - Loveseths Ltd. Consulted for years and to this day still use Mapper - Coolice on NT server 4.0 for own business and customer web sites. MAPPER and I were made for each other... written inventory, order entry, accounting, plus many other applications. Lots of memories ... trips to Roseville with clients (City of Edmonton - Western Supplies - Alberta Blue Cross) even got to fly in the Univac Corporate Jet... (pictures to prove it!) I've got an old 1720 sorter ... lots of unique items from 9480, 1110 and other computers.. even complete and working Sperry UNIX computers model 30 and 50 .. plus a complete Unisys Unix computer (expansion cabinet plus 2-cabinets - can't remember the model.. plus all the manuals... plus reel to reel 16-mm movie (I think 9480), plus 80-col card gauges, plus other publications... Just could never get rid of all this.. Keep up the good work.. your documenting of the legacy of computers is awesome and more need to know about it.

Best regards, Lyle Mozak Edmonton, Alberta Canada

![]()

2.8 Keith Myhre, 1972 - 1991

I hired into Univac on July 5th, 1972 after graduating

with a Bachelor of Electrical Engineering (BEE) degree from the University

of Minnesota. At the time, there were few new hires, but the JPTDS (Junior

Participating Tactical Data System) project was staffing up - Carl Rock

and I joined the project together. Our supervisor was Norris Nielsen,

and our manager was Dick Kuhns. When I was told I’d be programming

the ICKCMX (Integrated Circuit Keyset Central Multiplexer) POFA (Programmed

Operational Functional Appraisal), I had two questions: 1) What is an

ICKCMX? 2) What is a POFA? Eight months later I was at Puget Sound Naval

Shipyard in Bremerton, Washington debugging the program.

Carl Rock and I were two of the first Univac employees to take

engineering classes at the University of Minnesota via UNITE (UNiversity-Industry

Television for Education). At lunch time, we would head down to the

education department in the basement to watch TV. The TV was black &

white, not color, and we had a push-to-talk microphone to ask questions

of the professor while he (there weren’t any “she’s”)

lectured. We both received MSEE degrees without ever having to set foot

on campus to attend class. Although it took me six years to get my master’s

degree in electrical engineering, I was able to do it while working

full time, and with Univac paying for the majority of the costs via

tuition reimbursement.

In late summer of 1976, I was asked to go on a six month temporary

assignment to Ulm, Germany as a combat system engineer to work with

team member AEG-Telefunken on the F-122 Frigate proposal for the German

Navy. Two weeks later I had a passport, my household goods and Bricklin

were in storage, and I was on a flight to Germany. Team leader Al Bettis,

along with the other Sperry Univac team members Morley Moe and Clyde

Ketelson, were already on site, and Marketing (Gene Schultz) wanted

me in Ulm as soon as possible. So I was put on a Northwest flight to

Chicago, where I flew Swissair to Zurich and Lufthansa to Stuttgart.

Economy class on the Swiss Air flight was full (this was before the

days of business class), so I was booked into First Class – my

first and last time! When the Northwest flight landed at O’Hare,

the flight attendant paged me to meet a Swissair representative at the

door. I was the first person off the plane, where the Swissair representative

escorted me down the jet way stairs and walked me across the tarmac

to the Swissair First Class Lounge. I was impressed, thinking that I

could get used to international travel! After landing in Zurich, I had

a four hour layover for my Lufthansa flight. The jet lag, combined with

drinks in the lounge and on the flight over the Atlantic, made me sleepy.

So I took a nap in the main airport lounge. When I woke up, it was still

an hour before my flight departure – no problem, right? Wrong!

That was my first introduction to stringent European airport security,

where paramilitary soldiers patrolled the concourses carrying automated

weapons. And to buses that transport passengers from the terminal to

the aircraft. I got to my gate 20 minutes before the scheduled flight

departure, only to find out I was too late. The last bus had already

left for the plane! Six hours later I was finally in Stuttgart, and

on to Ulm for the next six months. The Sperry Univac/AEG-Telefunken/Bremer

Vulcan team won the F-122 Frigate competition, affording a number of

Sperry Univac personnel the opportunity to go on temporary assignment

in Bremen, Germany for development of the F-122 Frigate.

Following my return from Ulm, Germany, I was the project engineer

on the concept definition of the SHINPADS (Shipborne Integrated Processing

and Display System) Serial Data Bus. Other team members that designed

the SHINPADS Serial Data Bus included Dick (Ole) Olson, Steve Anderson,

and Ross Starkson. SHINPADS is a distributed system architecture for

a shipboard combat system. The chief architect was LCDR John Mathewson

of the Canadian Navy, who based his master’s thesis on SHINPADS.

The Canadian Navy specified the SHINPADS Serial Data Bus as the interconnect

system in their Canadian Patrol Frigate (CPF) RFP. Since I was an “expert”

on the SHINPADS Serial Data Bus, I was assigned to support the Hollandse

Signaal Apparaten (HSA)/Litton proposal development team and was the

only Sperry Univac person on their team. Everyone else worked on the

winning CPF team! I spent the better part of six months at the HSA/Litton

facility in Longueuil, Quebec (across the St. Lawrence River from Montreal)

helping write their proposal.

Navies around the world had a great deal of interest in the CPF combat

system architecture and the SHINPADS Serial Data Bus. At the request

of International Marketing, I made dozens of presentations to potential

naval customers in Germany, Italy, Spain, Turkey, Greece, the Netherlands,

Great Britain, Japan, South Korea, and Australia. Despite all of the

interest, no navy other than the Canadian Navy has implemented a distributed

processing architecture like SHINPADS. Interestingly, my wife Tricia

(Patricia Bailey Myhre, who has worked at the company since 1976) and

I were vacationing in San Francisco in October 2005. It happened to

be Navy Fleet Week, and several Canadian Navy ships were docked at the

Embarcadero, including a Patrol Frigate. We stopped a LCDR who was leaving

the ship, and asked him whether SHINPADS was still in use. He stated

it definitely was and was certainly familiar with it, even though it

wasn’t his area of responsibility.

In 1978 Sperry Univac Defense Systems Division was teamed with

a German shipyard (Bremer Vulcan) to build several frigates for the

Imperial Iranian Navy. The shipyard would build the ship, and DSD would

be the combat system prime contractor and system integrator –

a heretofore role never performed by DSD. Joe Stoutenburgh assigned

Dale Klette to head the program office. Dale drafted Ron Favorit, Lou

Besser, Gary Reetz, and me to be the core team to define the combat

system, develop system specifications, define statements of work for

subcontractors, write the proposal, and do everything else required

of a shipboard combat system prime contractor. The five of us were crammed

into a single room in the lower level of Yankee Square, with me being

the only non-smoker. Working seven days a week, long working lunches

at Lean’s (affectionately called Building “E”) at

Highway 3 and Diffley Road were not uncommon. Unfortunately, the Shah

was overthrown by the Revolutionary Guard in January 1979 and the project

was cancelled.

Univac developed the Tactical Support Center (TSC) in the 1960’s

to perform P-3 mission planning, crew briefings/debriefings, and mission

analysis. The TSC used the P-3 onboard computer, CP-901. Later, the

TSC was renamed the Anti-Submarine Warfare Operations Center (ASWOC).

From 1983 to 1986 I was the marketeer for the ASWOC Upgrade program.

Sperry Computer Systems Division pursued the U.S. Navy acquisition as

a prime contractor, with Lockheed Martin, General Dynamics, and BTG

as team members. Part of our ASWOC strategy was to institute an incremental

computer upgrade, including replacing the CP-901 computer with a CP-901A

(same form factor but all new innards). With only about 20 computers

needed for the ASWOCs around the world, we couldn’t justify amortization

of the non-recurring costs over such a small quantity. To alleviate

this, we enlisted the support of the airborne P-3 community to replace

the onboard CP-901 with the same ASWOC CP-901A. When Sperry & Burroughs

merged into Unisys, SDC took over the lead in pursuit of the ASWOC Upgrade

program, and the ASWOC computer upgrade died on the vine. Interestingly

though, the concept had legs and eventually ended up onboard the P-3

aircraft as the CP-2044 computer.

Reduced DoD budgets and a changeover from custom designed computers

to COTS (commercial off the shelf) equipment resulted in layoffs and

plant closings in the mid to late 1990s. In 1989 I began a new role

heading New Venture Business, reporting to Jay Jones, VP of Marketing

at Unisys Electronic and Information Systems Group (EISG), our division

moniker at the time. In this role, I was responsible for the identification,

pursuit, and development of non-traditional business opportunities by

leveraging EISG core technologies and capabilities into non-DoD projects/products.

As part of the task of educating EISG on the changing business climate

and the resulting paradigm shift, I made 66 presentations in six months

to 5,000+ employees throughout the U.S. to provide a company business

update and solicit new business ideas, and also instituted an electronic

bulletin board on MAPPER to solicit new business ideas from employees.

By 1991 I had trained myself well enough in new venture business,

that when an entrepreneurial opportunity “knocked”, I answered

the door and joined a start-up company in the field of RFID (radio frequency

identification) and pet micro-chipping.

![]()

2.9 Pat (nee Bailey) Myhre, 1976 - 2007

I graduated from Creighton University in 1976

with a BSMath degree. My college advisor suggested that I apply to a

company called Univac. So, off went a resume and application to which

I received a very polite rejection letter, but was called three weeks

later to come in for an interview.

That one and only interview resulted in my obtaining employment

at Corporate Square, Building C working on the Iranian DD993 program

in software test with Mark Roline as my supervisor. At that time, I

didn’t know the word “mentor”, but in retrospect I

had many and among them were: Tom Lunney, Denny Abbot, and Jerry Osieki.

In those days, we worked hard and played hard – we worked a lot

of shifts, long hours, and weekends but there were also the happy hours,

softball leagues, and project picnics which allowed people to let off

steam and just have fun. The DD993 program essentially came to a halt

when the Shah was ousted in 1979. A few of us were left to finish some

items as the DD993 and her sister ships were destined for the U. S.

Navy.

Next was a temporary assignment to Mare Island, CA in 1980 on

the Marine Air Traffic and Landing System (MATCALS) program. The team

that was assembled to work MATCALS came from various locations of Sperry

(as we were then called). Bob Wright and I were to be responsible for

the software testing. I was used to working with NAVSEA personnel and

working through the comment and comment resolution phases for documents

in order to reach an acceptable document for the program and the Navy.

On MATCALS, I lost count of how many times the test plan was rejected

with no accompanying comments. Each time there would be a meeting with

the Navy representatinv and when asked what was wrong with the document so that

we could correct it, he said “I can’t tell you that” –

there had been some scandal and therefore an overwhelming reluctance

to make comments in fear it would be interpreted as Sperry being told

how to do their work. How frustrating and how very difficult it was

to try to pick from thin air what should be changed or improved. Shortly

before I left MATCALS in August, 1980 the test plan was finally accepted

and if I spend any time thinking about it, I’m still not sure

how that happened. I never did see a working system and as I understand,

the successful program that did result was one that I probably wouldn’t

have recognized.

I had a stint that was less than a year but seemed like a lifetime

on the Israeli 6977 communications program. We were sequestered in a

locked room at Corporate Square, Building D and I never did get meaningful

work. I was working “with” some extremely intelligent people

who had come from Bell, but who never quite saw me as other than a pseudo

secretary. This was still in the days of very few females in the industry

and these were chauvinistic personalities. Fortunately, I was so inconsequential

that when the program was terminated and the lawsuits started, I was

not stopped from seeking other work.

By 1981, International Navy Systems was short of work. Mark Roline’s

entire test group (which by now consisted of me, Bob Buth, Daryl Beckmann,

AiLinh Li, and Joanne Nagel) was “loaned” to Underseas Systems

to work software test. Our boss there was Mike Haugen. The loan arrangement

became a permanent one when International Navy Systems ceased to exist.

This was my first experience of working at the Military Engineering

Test Center (METC) on Minnehaha Ave., the original home of ERA. We had

the infamous patch panel which allowed configuration of two systems –

if you could find cables long enough to reach where they needed to go

and that worked, and didn’t kill yourself during the re-cabling

process. Gene Achterberg was in charge of METC and to this day, I remember

the many phone pages – Pat Bailey (or whoever) line 7733. One “unique”

experience while working at METC was being snowed in at the plant with

Joanne Nagel and several others during a winter blizzard – it

wasn’t exactly the Ritz Carlton to begin with and there were no

perks for the weary lab rats who tried to make the most of being stuck

at Plant 2 with nowhere to go. I was able a make a trip to Groton, CT

as part of a trouble shooting team during my time on the program and

therefore had my first opportunity to see where our software was to

be used. What a neat experience. It was also during this time that Tom

Clancy wrote “Hunt for Red October” which gave millions

of readers a glimpse into some of what we worked on at Sperry.

In 1986, I had a great opportunity to work in Australia on the

RAN DDG program for 3 months. As a result of this, I had the pleasure

of meeting John Booher, Jim Miller, Don Tredinnick, and others from

Eagan who were either on temporary assignment at that time or who made

frequent trips “down under”. It also enabled me to see a

part of the world that I had not experienced before.

I briefly returned to Underseas, but soon was working on the

Canadian Patrol Frigate (CPF) program. I performed some software testing

but worked as a lab shift leader for Tom Lunney and Mark Roline. As

the system was being put together in Montreal, I returned to the test

arena and made many trips to Canada to help with test and integration.

After CPF, I worked my first aircraft-related program, which was the

Airborne Battlefield Command & Control Center (ABCCC) program for

the Air Force, again performing software test. Our hardware and software

system was housed in an enclosed capsule that was loaded into the belly

of a C-130. I worked with Don Tredinnick under the management of Burt

Gunderson. Once more, we were making the trek to Plant 2 to work in

the capsule. Late nights in the warehouse area on the east end of Plant

2 could be spooky at times and more than once I about jumped out of

my skin when the guard poked his head inside the capsule to see how

things were going. I decided that working alone at Plant 2 under those

conditions was not a good thing for me or anyone for that matter and

more thought was put into having teams in place during the different

shifts. The highlight of ABCCC was being able to be on a couple of test

flights from the Air Force Reserve Base at the Minneapolis Airport.

After ABCCC, we closed the doors to Corporate Square to make

the move to Plant 8 and my long career in the Maritime Patrol Aircraft

(MPA) area began. In 1990, I started in software test for the CP-2044,

which was the upgrade of the software and capabilities for the P-3C

aircraft. It was through this program that I met Art Francis, Tom Rougier,

Hue White, and John Rachac, among many others. I was again working for/with

Bob Buth. From CP-2044, the natural progression was to the Anti-Surface

Warfare Improvement Program (AIP) in 1994, which took CP-2044 and transformed

it with color displays and other hardware and software upgrades. In

the ensuing years, AIP has also made huge changes which keep the P-3C

MPA performing a vital role for the U.S. Navy. I again worked for Burt

Gunderson and it was from his urging that I moved into an aircraft integration

role along with the software testing. I made many trips to Greenville,

SC, and Patuxent River, Naval Air Station (NAS) to test the AIP aircraft.

I was one of only a few people from Lockheed Martin – Eagan (and

the only female) who became flight qualified with the Navy to allow

me to fly along on test flights. My software test and aircraft integration

continued on the Upgrade Improvement Program (UIP) for the Royal Norwegian

Air Force (RNoAF) to bring AIP to their P-3s. No trips were originally

planned to Norway, but I was able to go three times to Andenes (above

the Arctic Circle) to the Andoya Air Station. I assisted with software

testing on the Block Modification Upgrade Program (BMUP) and the Capabilities

Upkeep Program (CUP).

Still in the maritime patrol aircraft domain, I’ve recently

changed services and aircraft, now working on the Coast Guard Deepwater

program. The Medium Range Surveillance (MRS) program is being deployed

on the CASA HC-235A and Long Range Surveillance (LRS) soon to be deployed

on the C-130J.

So, in almost 31 years with Univac/Sperry Univac/Sperry/Paramax/Unisys/Paramax/Loral

and finally Lockheed Martin, I’ve been involved with surface ships,

submarines, and aircraft for the Navy, Air Force, Marines, and Coast

Guard along with foreign allies of the Australians and Norwegians. In

1976 when I was newly employed, I never envisioned a career that would

offer so many opportunities and the great people whom I’ve met along

the way. ![]()

2.10 Bob Myller, 1957-1999.

The 50’s: My first hints of interest in electrical engineering occurred in high school when my Physics teacher, Walter Schwede, a rather soft spoken, run silent run deep sort of a guy, explained electricity, ohm’s law, etc. with such clarity that I was impressed and hooked. While most of the other kids couldn’t handle all the imagination it took to deal with the abstract, untouchable, nature of electricity, Mr. Schwede took a liking to me and spent extra time explaining things and helped me develop my understanding; I even became a ham radio operator and learned how to fix radios. When I finally graduated from Moorhead Hi in 1953, I was almost sure that EE was going to be the way to go. I had some fleeting interest in Architecture but EE was confirmed when I flipped a coin and it came up with the EE decision. The following fall I enrolled at North Dakota State University in Fargo and started my four-year trek to a BSEE degree. During my later high school and for most of my college years I worked in TV and radio repair; all vacuum tubes in those days, of course. Anyway, it paid for my tuition; all of $44 per quarter! Can you picture me on that long hike between the Sigma Phi Delta Frat House and the North Engineering Bldg at NDSU on a cold windy January day with my brief case full of books and a slide rule conspicuously dangling from my belt?

My first real engineering job was at Wright Air Development Center in Dayton, Ohio, as a summer student in 1956. One of the highlights that I remember was one day the summer students were on tour in the big new IBM computer center. I don’t remember how many thousands of vacuum tubes it had but the guy describing the system said that they had now reached a major milestone in performance by achieving error free operation for almost one hour! Unknowingly, this was my first introduction to MTBF (mean time between failures).

During my final quarter at NDSU, in1957, I went on several interview trips to prospective employers. Times were very good then and most us received more job offers than we could possibly deal with. I think I still have letters of offer from 44 companies! Some of the companies I visited were: Collins Radio Cedar Rapids, Motorola Chicago, Cook Research Chicago, RCA Camden NJ, Stromberg Carlson Rochester NY, Honeywell Minneapolis, General Mills Minneapolis, and Remington Rand Univac St. Paul.

I soon made my final decision and started at Univac in July 1957. I was overwhelmed by their generous offer of $425 per month! My personnel advisor was Earl Juhl and he brought me from Plant 1 on West 7th up to Plant 5 in the St. Paul Midway district. He introduced me and handed me off to Bob Madvig head of the TACS/BADGE Engineering group I was assigned to. His opening remark was: “We don’t have enough chairs for all you new guys we’re getting up here!” I was part of the pool of engineers being reserved for the expected new BADGE (Ballistic Air Defense Ground Environment) Air Force Contract. For the rest of the summer most of us newcomers had little to do but read books and take classes hoping to beef up our meager knowledge of digital engineering techniques. By late summer of 1957 we learned that the BADGE program had been cancelled. Would this be our first exposure to a mass layoff? No! The company treated us very well and managed to integrate most of us into other existing programs within the company.

One of my first days on the job in July and still not used to the constant paging over the Public Address (PA) system I noted that the operator had left her mike on and we became aware of the background chatter in their room. Suddenly and loudly over the PA system the operator screeched “ooo, Wally, quit that”! Then quickly the PA mike went silent but the entire plant 5 burst out in laughter and many went looking for “Wally”.

I was assigned to the TACS (Tactical Air Control System) just entering its early first build stage. This was a hodge-podge of analog and digital equipment all packaged up into helicopter transportable boxes. I remembered that the biggest problem was keeping all those myriad cables and connectors working for more than one hour at a time. It was so hot in Plant 5, prior to air-conditioning, that we were allowed to work the graveyard shift. I got to design some of the production test and simulation equipment - not real exciting but I figured I had to start somewhere, and, yes I used my favorite vacuum tube, the 12AX7, to build a series of blocking oscillators to produce range rings on the display screens!

In January 1958 I was granted a three-month leave of absence to go on active duty in the US Navy. This amounted to Boot Camp at Great Lakes, Ill, after which I was back at Univac. I was assigned to the Minuteman Program designing field test equipment, but now with transistors.

The 60’s: I jumped at the chance to get in on the early stages of the NTDS (Naval Tactical Data System) Program. My first boss there was Curt Christenson, he came looking for me because I was from NDSU, his Alma Matter of a few years earlier. He thought the North Dakota people had a good work ethic! I worked with Cliff Ashe on the design of the IDAC (Interconnecting Digital Analog Converter) connecting the ‘Q-17 computer with the analog weapons fire control system; I also worked on Keyset Central, Keyset Central Multiplexer (KCMX) and other segments of the NTDS. Most of the boxes were the size of refrigerators. I remember going over our design with guys like Dave Lundstrom and Bob Burkholder. By 1961 the first systems were being installed on three naval ships: two destroyers and one aircraft carrier. At this stage I was making many trips to San Diego helping to get all “this stuff” working on board the ships. We were caught in the midst of opposing factions in the Navy; the conservative ones saying it would never work and the younger ones pushing hard to make it work. Any setbacks during the integration were, of course, used to threaten us with extinction. One Navy friend of Univac, Lt. Commander Radja, kept us encouraged during the hard long days (and nights) with many setbacks. We would often work 36 hours over a weekend without a break while the ships were in the harbor. Then we would fly back home and work on hardware and software fixes for the latest problems and bring them back to San Diego the next weekend only to do it all over again. I remember that Jay Kershaw was a great encourager to me and other young engineers during those early NTDS years.

Little by little by little we got it all working and the unbelieving factions begin to quiet down and even join the new digital age. Soon we began looking at tactical systems for Naval Submarines and Naval aircraft. Key people I worked with during these years leading the NTDS expansion were: Jim Ketchem, George Workman, Bill Geiger, Bob Scholz, Jack Sater and others in Systems Engineering. Key hardware guys that made this stuff work were: Al Kasyinski, Bob Phelps, Al Arndt, Cecil Metz, and others. We all worked for a number of years in Peripheral Engineering under Don Vizanko and Red Phillips; great guys to work for! We had several subcontractors that worked tirelessly along with us during these times also: Kearfott and Ford Instrument come to mind that I was close to.

International opportunities began to appear from the Navy’s of Germany, the Netherlands, England, Greece, Japan, etc.