Information Technology (IT) Pioneers

Retirees and former employees of Unisys, Lockheed Martin, and their heritage companies

People I-L, Chapter 14

1. Topical Article Contributors

These 39 writers have contributed 73 technical articles or tidbits, some complementing career summaries:

- Jim Inda, Ron Irwin, and Gary Isliefson.

- Bob Jablonski, Peter Jankowiak, Bernie Jansen, Tony Jenkens, and Glen Johnson.

- Bob Keenan, Ralph Kerler, Dick Kistler, Jim Ketchum, Frank Kline, Bill Klingner, Elwood 'Woody' Knight, Michael Knight, Mike Kokesh, Dave Kolling, Steve Koltes, Tom Kratz, Jim Kucera, Dick Kuhns, and Dr. Vipin Kumar.

- Archi Lahti, Andy Lang, Bob Langer, Ernie Lantto, Jack Lavers, Capt. Donald Leichtweis, James P. Lenfestey, Jacques Lignieres, Earl Lillistrand, John M. Lindley, Paul Lindquist, Tom Lindquist, Mike Lins, Don Lovely, Dick Lundgren, and David E. Lundstrom.

2. Career Summaries - I:

2.1 Ron Irwin, 197x - 2000

I received access to this web site today and found it very interesting. You probably don't remember me, but I did run into you from time to time over the years I worked on MATCALS at Mare Island. I worked with Gordy Erickson and managed the software development work on Mare Island for MATCALS. After the island closed in September 1995, I commuted to San Diego for 5 years, continuing maintenance of the MATCALS software until I retired from LM in 2000. After that I have continued to support SPAWAR in San Diego on a part-time consultant basis. Even now I am just finishing an 8-week task in January with what I believe will be my last support of MATCALS. Yes, MATCALS is still being supported by Lockheed Martin (LM) in San Diego by two programmers and a field engineer.

MATCALS is still being used by the Marines in Iraq and elsewhere

with 1980 technology. The latest software update brought MATCALS

TADIL-B up to the current standards. Sperry, Unisys, and Lockheed

Martin built a great system that still has not been replaced by a

"modern" ATC system, so the Marines continue to use MATCALS and

SPAWAR is continuing to maintain it. It still uses the original

AN/UYK-44 embedded computers, but has had the FOG display replaced

with a new display. It is expected to be fielded for at least

another five years before the replacement system is fielded. As you

know, "the company" built the TPS-70 ATC radar, the CCS shelter,

MMDs, computers, and software for MATCALS. The only piece of the

system built by another company was the TPN-22 final-approach radar.

I find it remarkable that the system originally fielded in the mid

1980's is still being maintained and used. All who worked on MATCALS

hardware and software over the many years built a great system that

is like the bunny that just keeps going and going and going. The

SPAWAR Systems Center in San Diego is maintaining the hardware and

as I said, LM is still supporting the software. I hope someone can

provide more info about MATCALS for the web site.

There should be some retirees in your group that can provide good info

on MATCALS. I look forward to viewing additional info on all that you

have planned to be included. Yours in retirement from LM, Ron Irwin

- Napa, CA.

2.2 Pierre Iskos, 1965 - 1996

The Field Engineering Department of Sperry Univac

Defense Systems hired me in February 1965. Specifically, to support the

Apollo Space program, that was just beginning. After some basic training on the type 1218 and 1219 computers

and peripherals; I started working with the design engineers Bob

Oulicky and Don Mager doing design test of the new 1230 computer

which was designed specifically for the Apollo Project. Reference

http://vipclubmn.org/CP30bit.html#Type1230.

The Field Engineering Department of Sperry Univac

Defense Systems hired me in February 1965. Specifically, to support the

Apollo Space program, that was just beginning. After some basic training on the type 1218 and 1219 computers

and peripherals; I started working with the design engineers Bob

Oulicky and Don Mager doing design test of the new 1230 computer

which was designed specifically for the Apollo Project. Reference

http://vipclubmn.org/CP30bit.html#Type1230.

In October 1965 I was sent to Goddard

Space Flight Center with several other engineers to provide

technical support to NASA personnel as well as to the 100+

Univac on site programmers. Six

months later I was promoted to be the site supervisor; a position

that I held until requesting a transfer in December 1971.

In October 1965 I was sent to Goddard

Space Flight Center with several other engineers to provide

technical support to NASA personnel as well as to the 100+

Univac on site programmers. Six

months later I was promoted to be the site supervisor; a position

that I held until requesting a transfer in December 1971.

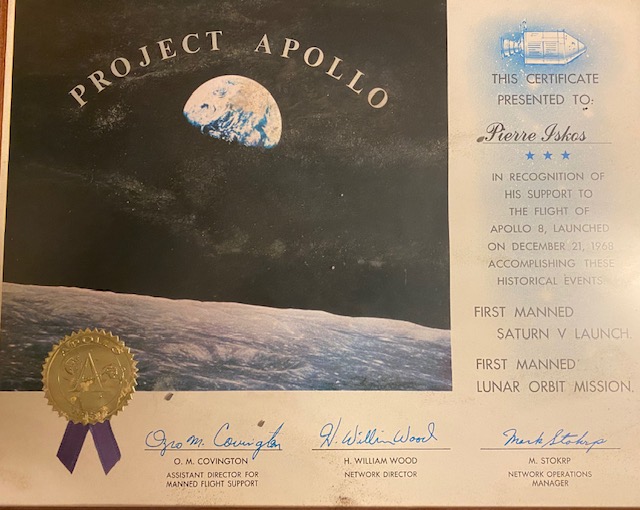

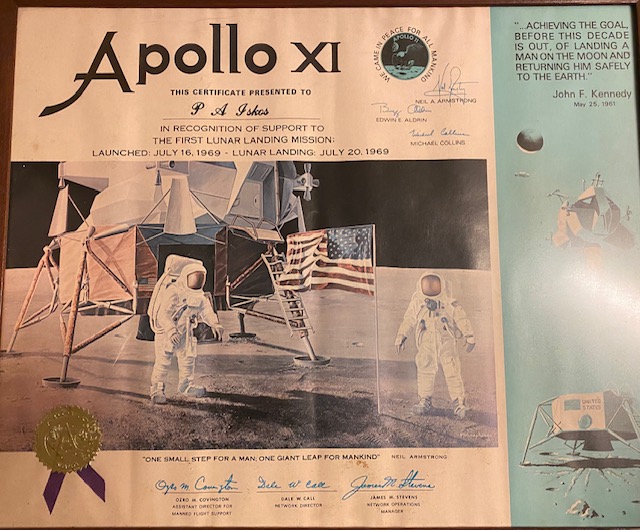

At peak time we had 12 Apollo Project support engineers, half of them on various sites around the globe. Shown here are scans of two of my four Apollo mission support certificates.

In December 1971 I was sent to Germany

to provide technical support to the German Navy and to the

programming team at the Wilhelmshaven Naval Base.

We were working on development of the Fast Patrol Boat system. I stayed there for nine months then moved to Bonn/Bad

Gödesberg.

In December 1971 I was sent to Germany

to provide technical support to the German Navy and to the

programming team at the Wilhelmshaven Naval Base.

We were working on development of the Fast Patrol Boat system. I stayed there for nine months then moved to Bonn/Bad

Gödesberg.

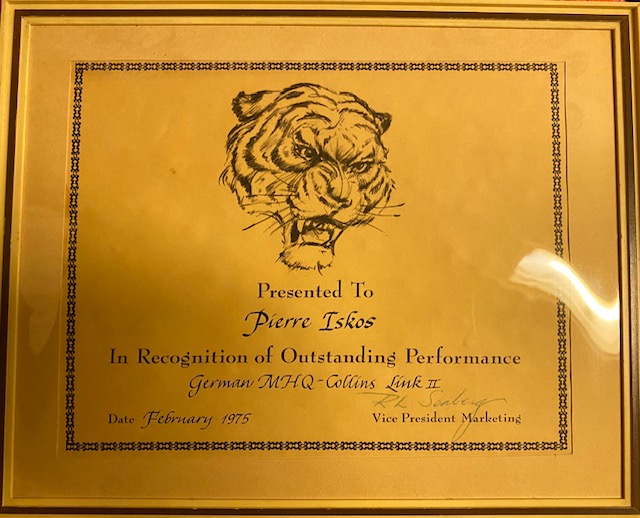

There I provided systems engineering support to marketing. At the right is a 'Tiger Award' from VP Dick Seaberg for the German Navy Link-11 system. In Bonn, I also lead marketing initiatives for southern Europe and the Middle East.

In 1976 we won a successful contract with the Greek Navy,

The Greek Submarine Program. This was the Kanaris

submarine fire control system. I was sent to Greece to be the in-country marketing

representative for Greece and the middle east, interfacing with the

Greek government, etc.. At the left is recognization by VP Jim

Rapinac.

In 1976 we won a successful contract with the Greek Navy,

The Greek Submarine Program. This was the Kanaris

submarine fire control system. I was sent to Greece to be the in-country marketing

representative for Greece and the middle east, interfacing with the

Greek government, etc.. At the left is recognization by VP Jim

Rapinac.

18-years later, July 1994, the Company brought me back to St. Paul

to work with various marketing teams -

then was laid off in March of 1996.

This may sound as an uneventful career; but for me it was very exciting and challenging. I had opportunities to work on some interesting projects like the Apollo Project and to work with many very capable people. I believe I left a good name with those co-workers who got to know me. Since leaving the company in 1996 – have kept in touch with former co-worker Keith Myhre, (http://vipclubmn.org/People5.html#Myhre) et al’.

Background: I was born in Greece but immigrated to

the US at age 17. I became a US Citizen, then went

to college at the University of Illinois, graduating in 1964 with an

Electrical Engineering degree.

![]()

Best Regards, Pierre

3. Career Summaries - J:

3.1 Clint Jurgens, 1971-1988

Like so many at Univac I grew up on a farm, got

a technical degree from the state university, and found myself working

in the new field of computer technology at Univac. However, instead

of being from Minnesota, the Dakotas, Wisconsin, or Iowa; I grew up on

a horse and tractor on the high-plains of Western Nebraska. Our family

farm was split between raising cattle and wheat.

Growing up in a rural area usually meant that you attended a small high

school. I had eleven in my high school class and went from there to

the University of Nebraska, receiving my BSEE in 1965 and MSEE in 1966.

After the University of Nebraska I went to Officer Candidate School,

becoming a second lieutenant in the USMC. The Marine Corps wanted me

to go to the infantry; however, I thought I could make a better contribution

if I could use my EE training. Although the folks making the assignments

could not provide any assurance they did assign me to a Marine Air Control

Squadron at Camp Pendleton. My unit was in the process of rotating back

from Vietnam and we were reforming at Camp Pendleton with all new computer

driven equipment. At that level we were users and not developers, and

I became an air intercept controller using the computer processed radar

information to guide fighter pilots into the right position to shoot

down the enemy fighter.

In the fall of 1967 the

executive officer calls me into his office one day and says, “Lieutenant,

we have a quota to send someone to programming school and you are the

only one qualified.” The catch was an agreement to spend three

years on active duty after graduating which meant an extra 15 months

of active duty. I agreed and found myself at the Fleet Computer Programming

Center, Pacific in San Diego learning all about and how to program the

Univac CP-642B and its Marine Corps version, the CP-808.

After graduating from programming school I was transferred from Camp

Pendleton to Marine Corps Air Base, El Toro in Orange County California.

I was assigned to another Marine Air Control Squadron to work on a project

called the Southeast Asia Interface. As it turns out the Marine Corps

had the only system (the AN/TYA-20 from Univac) that could be programmed

to perform functions similar to a modern day router, linking all the

air defense systems in Vietnam together. The project was well underway

and I became the third member of the programming team. The other two

members of the team soon left and I became the principal programmer.

I felt very fortunate to be assigned to a technical job doing data communications

programming for the Marine Tactical Data System.

This

project was built and tested with the Air Force and Navy in Southern

California and then deployed to Vietnam. Doing the programming was the

easy part. Getting the resources was the challenging part. I was lucky

again, the gnarly, well-respected maintenance chief was CWO-3 Dante

A. Massarotti and one of his bright young technicians was SSgt

John Westergren. Gunner Massarotti and the electronics officer

went to the Navy and extracted a junked RD-243 magnetic tape unit that

they refurbished. This was a great improvement over paper tape.

In addition, the Univac field engineer, Dennis Angel, taught me all

about DS-4772 and how to program Input/Output (I/O). In order to compile

our software we either had to drive to FCPC in San Diego or drive up

to Pt. Magu. Many times we would go to Pt. Magu when they were not supporting

a missile shoot and work all night. Eventually we were able to get a

driver with a security clearance and we would send him to San Diego

and have him wait for the results.

The program was deemed fully

operational in the spring of 1969 and we took it to Vietnam in June,

making it back in time to watch the lunar landing in July 1969.

After successfully deploying the software I received my orders to return

to Vietnam for a year long tour. Unknown to me, the commanding officer

of my unit thought that I could be more useful to the Marine Corps if

I were able to apply the lessons learned from the Southeast Asia Interface

project to the emerging data communication standards for Air Command

and Control. My orders were cancelled and I spent my last year of active

duty doing a small part to establish the Marine Corps Tactical Systems

Support Activity as the Marine Corps center for tactical command and

control systems.

With my tour of duty approaching an end I decided

that I would not go to work in the defense industry and was able to

secure a system engineering position with Electronic Data Systems (EDS).

I thought that I was headed for their data center in Dallas, TX. Halfway

from Southern California to Dallas via Nebraska the folks at EDS contacted

me and wanted me to go New York City instead. That did not appeal to

me and after some discussion I ended up on Des Moines, IA. The job was

not technical at all and one I did not like. So, I called my friend

Danny Massarotti and asked him if there were any jobs at Univac.

He thought there might be one and fortune smiled once more with a Sr.

System Engineering position in Ground Systems at Univac Defense Systems.

July 1971 was the start of my seventeen-year

career at Univac Defense Systems. I had already been programming Univac

computers for several years and felt right at home. The company was

at the leading edge of technology, a good place to work, and I enjoyed

the people.

This time frame was the dawn of the

sixteen bit computer and I helped put together the AN/UYK-20 winning

proposal that eventually led to my first project engineering job, updating

the AN/TYA-20 from the CP-808 to a cluster of four AN/UYK-20 computers.

The CS-1 code used in the CP-808 was updated to CMS-2 and we employed

MEANS statement to fully embrace structured programming constructs.

Since we had very limited space in the shelter we had to find a way

to use a single set of peripherals. Ethernet or Token Ring was not yet

available so engineering developed a shared bus device called the Data

Bus Controller or DBC.

We had a requirement to

interface with different types of serial communications that in no way

resembled commercial communications, eliminating the use of any off

the shelf commercial chip set. Glen Kregness came to the rescue with

a variable character length serial interface that was to be known as

VACALES. {Editor's note: Glen created the concept, Dick Erdrich did

the basic hardware logic design.}

As we were

getting to the end of the project the IBEW was in contract talks and

threatening to strike. That had the potential of preventing us from

delivering on time so the decision was made to ship the shelter to Camp

Pendleton (MCTSSA) and finish the software there. The challenge of finishing

on time was increased significantly, especially when we discovered wiring

errors. We finally did finish and the Marine Corps accepted the system.

The next big event was the MACCS-85 project.

This was the next generation air command and control system for the

Marine Corps. The company made a very large commitment to this program,

developing a strong team. I don’t think I’ve ever been in

such a large and close-knit team that worked grueling eighty-hour plus

weeks for two years. We had the right technical approach and the Marine

Corps liked it, but we did not win. I’d like to go back to the

evaluators and ask them to eat their words about our pricing. They dinged

our proposed display pricing because they felt we did not provide sufficient

justification for reduced semiconductor memory cost in the future. This

was one of the most ridiculous reasons ever. Lower semiconductor memory

cost has enabled a wonderful array of products like laptop computers,

iPods, digital cameras, and cell phones.

We might

not have won MACCS-85, but we set the stage for our next large contract,

the Marine Air Traffic Control and Landing System (MATCALS). The first

competitive procurement between MACCS-85 and MATCALS was winning the

Multi-Mode Display or MMD. That win, combined with our air traffic control

experience, NTDS, MTDS, SHINPADS, etc. positioned the company to win

the MATCALS program. This was one the first large command and control

systems with embedded computers linked by redundant serial buses. For

Sperry Univac it became a real showcase for switching, displays, communications,

distributed computing, etc. It also put Sperry Gyro in a good position

to win the air surveillance radar contract for MATCALS.

After so much time in Ground Systems it was time for something different.

I moved into Airborne Systems and worked special programs. Here is what

I can tell you about that experience _____________________________.

Let me just say that it was enjoyable and I thoroughly enjoyed working

with the airborne team. Everyone who worked special programs got to

know Ernie Ryan. {Editor’s note –

Ernie took care of security clearances and associated

facility access.} He ran a tight ship and it was fun for a former

Marine to link up with retired Navy guy. We even got along.

After the merger with Burroughs and the birth of Unisys I decided to

take a look outside the company. Sid Rundell had successfully ventured

out of Univac - I joined Sid in Lockheed Missiles and Space, Austin

Division. Shortly after I moved to Austin, Sid was offered the GM position

in Salt Lake City and I replaced him as the Director of Business Development.

Lockheed was much like the old Univac with great technical talent, always

on the leading edge of technology. The late eighties was the start of

the decline in the defense industry and there was not enough business

to support the large facility Lockheed had built in Austin.

In 1990 I could see what was happening and moved back to the Twin Cities

to work for a small high-tech commercial company, Ancor Communications.

After some entrepreneurial efforts and start-up management positions

at NEO Networks, NuSpeed, and Cisco - I retired in early 2003.

Lady luck has been nice to me throughout my career. I’ve always

had the opportunity to work with some the best and most talented engineers

and the companies I’ve worked for have been technology leaders

great at operations. The softest spot in my heart is reserved for all

my friends and co-workers and Univac Defense Systems. We were a bunch

of raw but talented folks who conquered the new world of high technology

and did some amazing things. I can’t wait to see what the next

generation will do.

![]()

4. Career Summaries - K:

4.1 Bill Kenny,

My original position at Univac was as an engineer

in the Process Control Research group in the Research Division, headed

by Dr. Leroy Stutzman. The Research Division had four departments:

Physics, headed by Sid Reubens; Math Research, headed by

Arnie Cohen; Process Control, headed by Jack Tierney; and a

Systems Department. The goal of the Process Control group was to research

the potential for computers in the analysis of chemical processes and

ultimately for process control. The analysis part was successful, but

the control part was premature. Computers in those days failed about

every few hours and chemical processes could not be allowed to fail

even over a period of two or more years. We had a great group: manager

Jack Tierney, Dale Ruud, Chuck Homan, Bob McCarter, Jim

Nikitas, Curt Brasket, and myself. Dr. Neal Amundson, head of the

Chemical Engineering Department at the University of Minnesota, was

a consultant. After a few years, the Research Division, except for the

Physics Group, was closed down as not profitable, and the staff migrated

to either other parts of the company or to other careers. We had published

papers on digital control and chemical process models, but could not

generate serious industry interest.

I joined

the Navy NTDS project as a section leader of a group developing algorithms

for military interceptor and AA missile control systems. Other projects

involved algorithms for the SPN-42 Automatic Carrier Landing System.

We used the Univac 1103 computer for our analyses. In this period I

had to travel extensively to various Navy facilities: Washington, China

Lake, Newport News, San Diego, and Los Angeles. In 1960 I spent a week

or two on an aircraft carrier (probably CV-62, the Independence) for

observing command and control and air operations. We planned to computerize

them in NTDS. During the ride a hurricane came up and the big ship really

bounced around. The carrier was summoned to aid a passenger ship that

had a seriously ill passenger. I remember going up to the deck and being

completely disoriented since it was totally dark—no horizon and

the ship was operating under battle conditions with no lights. I could

not even see the deck. I learned a lot about Navy customs and etiquette.

I made the mistake of showing up for dinner without a tie and suit—no

one would speak to me. Dinners in the officers’ mess required

suits and ties. We bunked in the pilots quarters that were under the

flight deck so it was pretty noisy, especially when the catapults were

operating. I was able to explore the entire ship. The chain locker impressed

me. This is a gymnasium sized room where the anchor chains are drawn

up. A link was about waist high on me. The scale was hard to believe.

The steam catapults were improbable designs but worked very well.

Other projects included developing algorithms

for missile tracking ships and for a tracking station on Ascension Island.

Some of my people had to go there but I worked that project from St.

Paul. Univac opened a branch office in Cocoa Beach, FL to support the

Cape Canaveral Launch Facility. I managed the facility from St. Paul

but we had a local manager on the site. We had about 40 programmers

there but the productivity was far less than that of the 30 or so we

had in St. Paul. The staff there was not as qualified for the tasks.

We solved the coordination problems by temporarily relocating key staff

to Cocoa Beach. I was always impressed when a rocket was launched. The

noise, especially in the low frequencies, was terrific.

In 1962 I left Univac to join with Leroy Stutzman in a new

startup, Tronchemics Research, Inc. with the goal of researching computer

applications for the chemical industry.

![]()

4.2 Dick Kistler, 1964-

Univac’s Radio Guidance of Missiles at Vandenberg Air Force

Base

I joined Univac as a programmer in April

of 1964 and was assigned to the real time missile guidance group in

Bob Hanson’s organization. Ed Solheim and Bob Russell were the

two managers in the organization and my immediate supervisor was George

Smith. The real time programmers in the group worked on the Athena computer,

which I was to learn was probably the most reliable computer ever built.

I attended an Athena programmer’s class although I never got to

write any guidance programs for the Athena.

The

Athena was originally developed to provide guidance to the Titan I Intercontinental

Ballistic Missiles (ICBM) that were housed underground. The guidance

computer needed to be extremely reliable but did not require much versatility

since the guidance equations were fairly simple. Targets for the ICBMs

were known in advance and implicit guidance equations (fly a wire trajectory)

were sufficient to get the job done and guide the missile to the target.

The program was stored on a large revolving magnetic drum that only

had room for 8K of instructions. There was a small “scratchpad”

memory for data. It contained 256 24-bit words of rewritable core memory.

One of the biggest challenges in Athena programming was spacing the

instructions around the drum so they would be under the read head at

the proper times. A basic instruction time was 40 microseconds and the

various instructions would all be some multiple of 40 microseconds.

Programmers developed the instruction spacing program on another computer.

The early space programs from Cape Canaveral and Vandenberg Air Force

Base used the Athena as the guidance computer. However, as missile guidance

technology evolved toward explicit guidance equations, where all the

targeting did not need to be done prior to launch, the Athena could

not provide the needed capability. Thus, the move toward more general-purpose

computers became the next logical step. This would lead to major changes

in philosophy as well as hardware and hardware interfaces.

Philosophically, a general-purpose computer meant that programmers could

very easily change the program in the computer’s core memory,

so many security processes needed to be developed to insure the integrity

of the guidance system. The hardware changes were extreme since the

new computer and all its peripherals would be much smaller than the

nearly 400 square footprint required by the Athena’s large cabinets.

Also, a new interface needed to be developed to tie the general-purpose

computer to the ground radar system. Univac engineers developed a small

(about 3 feet by 3 feet by 1 foot) Radar Interface Unit (RIU) that effectively

made the computer change transparent to the radar.

An Athena computer also guided the Air Force Program 437 on Johnston

Island, but the follow on program, Program 437AP, needed more sophisticated

guidance equations, and it was the first radio controlled ground guidance

program to be written on a general purpose computer. In late 1964 or

early 1965 a small group of real time programmers was assigned to develop

the new guidance program on a Univac 642B general purpose computer.

The small group consisted of Paul Becvar, Steve Chodos, Wayne Hiller,

Dick Kistler, Don Neff, Dick Olson, and Wayne Walther. We were given

Special Access clearances and sequestered in a small office area of

Univac Plant 1. The team not only programmed the real time guidance

equations per a specification from another contractor, but also designed

and developed the real time executive that would control the program

and interface with the new RIU. The team also designed and developed

the non real time support software that was needed. All the real time

software was written in the CS-1 assembly language. The assembly language

programming enabled more efficient programming and (we believed) more

reliable programming that could be more easily debugged.

Shortly after we finished the Program 437AP programming we were given

a new task: to develop the guidance program for the Air Force Program

110 (a Titan IIIB booster and our Agena D upper stage) which would be

launched from Vandenberg Air Force Base (VAFB), CA. It was going to

be a much larger task than the 437AP task so the team was expanded by

the addition of several programmers: Larry Buhr, Ron DeMars, Bob Homyak

John Neeson and Jack Pittenger.

Starting in the

fall of 1965 the Program 110 programming team worked out of offices

in Univac’s Plant 1 in St Paul but spent considerable time in

Plant 5 where the computer system was setup. Members of the team who

developed the non real time portions were able to use the computer center

in Plant 1.

In December of 1965 Univac management

informed us that they were going to establish an office onsite at VAFB

and would be staffing it with the Program Manager and a staff of programmers.

It was to be a two-year semi permanent move with plans to return to

the Twin Cities at the end of the period.

The

team continued developing the guidance program and all the support software

until late February of 1966 when Charlie Gardner, Program Manager; Dexter

Pehle, Systems Engineer; Harold Tuset, Programming Supervisor; and six

programmers relocated their households to Santa Maria, CA. The programmers

who moved were: Larry Buhr, Steve Chodos, Ron DeMars, Bob Homyak, Dick

Kistler, John Neeson, and Jack Pittenger. Other members of the Program

110 team made prolonged trips to VAFB to help develop and debug the

software in preparation for a planned July launch. Dick Olson spent

almost all of the following five months (March to July) on site although

he did not move his household.

In addition to Univac the Program

110 guidance team consisted of Lockheed Missiles and Space Company (LMSC)

(Sunnyvale, CA), Bell Telephone Labs (BTL) (Greensboro, NC), and Western

Electric Company (WECO) (Winston Salem, NC and VAFB). LMSC, under the

guidance of Bill Chapin, developed the trajectory optimization software

that would provide the ideal trajectory for the launch. BTL, under the

guidance of Bob Tarrant, developed the explicit guidance equations that

would use the targeting information and provide the guidance commands

to be sent to the missile. WECO was the guidance station integrator

and provided the ground radar system as well as the antenna and radio

guidance box on the Titan IIIB.

The months of

March through June were a very intense period of final development and

checkout for the Univac programmers at VAFB. Everyone spent up to 12

to 14 hours a day, seven days a week, except for Easter Sunday, getting

ready for a late July launch date. Bob Tarrant was onsite for several

months as the equations were also being debugged using the WECO analog

simulator with the ground radar system. Also present were Del Driver

and Herb Lewis, two members of The Aerospace Corporation from El Segundo,

CA. As the technical advisors to the Air Force The Aerospace engineers

asked all the necessary, penetrating questions and evaluated reams of

data to ensure the guidance system was working properly.

Finally, in late July the guidance system was declared ready to support

the first launch of the Titan IIIB, Agena D. On launch day the countdown

was delayed for many hours as the launch team solved one booster/payload

problem after another. The guidance station was located under ground

in a former Titan I launch facility with no view of the outside or the

launch pad. Most if not all the programming team were present in the

guidance station in the unlikely event that they would be needed to

solve some unforeseen problem. Once it became obvious, after hours of

holds, from the countdown network audio that we were finally going to

launch in a couple minutes Harold Tuset and I went outside the complex

so we could view the launch. After all, we had seen countless simulations

and knew what everything looked like in the guidance station computer

center and we wanted to see the Titan liftoff, even though the launch

pad was about 10 miles from the guidance station.

As we stood on the hill above the guidance station without a worry in

the world, we soon realized that more than two minutes had passed and

we were probably in another hold situation. Then we heard shouting coming

from the tunnel leading to the guidance station: “Tuset, we need

you in here.” “Kistler, we need you in here.” Then

came our most embarrassing moments and probably career low points. After

all, Univac had never had a problem that caused a launch hold or a launch

failure, but we were informed that our guidance computer had just caused

the launch to be held.

To insure the integrity

of the software we had designed a feature in which the computer would

perform a checksum of the guidance program when the guidance system

was switched into launch mode. When the WECO guidance control officer

placed the guidance station into launch mode the computer dutifully

performed its checksum and, unfortunately for us, detected a checksum

error. This was not a problem that could be quickly solved and the decision

was made to scrub the launch and try again another day.

It did not take much analysis for us to find the cause of the checksum

failure. Using a technique we called core dump comparison, in which

we compared the entire core memory of the computer after the problem

with the core memory of the computer when it was loaded that morning,

we quickly found one instruction in the guidance program that had picked

up an extra bit.

Since timing pulses, data

and action interrupts from the RIU drove the real time executive, we

had decided to have the executive sit and wait in one place for the

interrupts. We did this by putting in an instruction that jumped to

itself, thus the program would cycle on the one instruction until it

needed to take action to process the next interrupt. During the many

hours that day that the guidance program was just cycling, processing

interrupts and waiting for the signal to go into launch mode it probably

spent 95% or more of that time executing the single jump to itself instruction.

As we found out later, the repetition caused that particular circuitry

to heat up and eventually the instruction picked up a bit that then

caused the checksum to fail when the launch mode was initiated.

Once we were able to point out the location of the additional bit and

explain the executive’s software design to the hardware engineers

they quickly deduced the overheating problem. They replaced the card

that had failed, we modified the real time executive to loop through

about ten instructions while waiting, and we reestablished the guidance

program software integrity to everyone’s (our Air Force program

office representatives, the Aerospace engineers, and the WECO guidance

station integrators) satisfaction. A couple days later on July 29, 1966,

we successfully guided the first Program 110 payload on its way to orbit.

That, as far as I know, was the only time

that a Univac ground guidance system was responsible for a launch hold

and it never was responsible for a launch failure. We continued to successfully

support Titan IIIB launches at a rate of about one launch every six

weeks for many years.

Not only did Univac

provide years and years of successful support but the information on

one of the guidance system peripherals was used to save a mission. One

of the guidance computer’s peripherals was a 30-inch by 30-inch

Milgo plotter. Prior to every launch the guidance program would run

the nominal mission and plot the expected flight trajectory on the Milgo

plotter. We displayed two plots: the downrange versus the cross range

plot and downrange versus the altitude plot. We would plot the nominal

trajectory plots in green ink and then plot the real time (whether it

was a simulation run or a real launch) in red. These plots were very

useful in the analysis of various dispersions during simulation runs

and the plots gave a real time view as to how well the missile was following

the nominal trajectory during an actual launch.

One day during the last two minutes of a launch countdown the final “go”

or “no go” decisions were being given on the audio network.

When the Launch Control Officer went down the list asking for readiness

from the booster, the payload, range safety and the guidance system

everyone said they were “green” except the Range Safety

Officer, who said the range was “red.” There had been a

power failure in the range safety system and the Range Safety Officer

had no information available from the range safety radars. For whatever

reason the Launch Control Officer did not acknowledge the “no

go or red” condition from range safety and cleared all systems

to proceed to launch. The Titan lifted off and proceeded nominally toward

orbit. It was the prerogative and probably the responsibility of the

Range Safety Officer at that time to send the destruct command and destroy

the missile and its payload since he had no visual information as to

the position of the missile. However, as he did during every launch,

the WECO Guidance Control Officer stood in front of our Milgo plotter

and gave a “play by play” commentary over the network as

to where the missile was with respect to downrange, cross range and

altitude and how close we were to the nominal trajectory. The Range

Safety Officer had enough faith in the Guidance Control Officer and

our trajectory plots that he let the Titan continue on to orbit. A day

that could have ended with a failed mission instead ended with a successful

launch thanks in part to our trajectory plots.

In the late 1960’s another major missile program development effort

was being planned for VAFB. That was the Air Force’s Program 467,

which was to be launched on a Titan IIID. Charlie Gardner had visions

of an expanded role for Univac for Program 467. For Program 110 all

the trajectory analysis, trajectory optimization and trajectory design

work was done by LMSC in Sunnyvale, CA, under the direction of Bill

Chapin. Charlie thought that if he could lure Bill Chapin and his key

people away from LMSC that the Air Force would be willing to give Univac

the trajectory contract as well as the guidance program contract. Charlie

successfully hired Bill Chapin and his key staff members: Dick Kallaus,

Jamie Lavios, and Ed Tilford. B ill then hired Bill Exely, who had worked

with NASA in trajectory analysis and simulation design for the Saturn

V moon rocket.

With such a talented staff

of trajectory experts working for Univac at VAFB the Air Force did indeed

give Univac the Program 467 trajectory contract. For a period of several

years the level of development at VAFB was at a very high pitch as 1230

computer systems were installed to support the Program 467 trajectory

optimization and design and the new guidance program development. All

the effort culminated in the successful launch of the first Titan IIID

on June 15, 1971.

During the first few

years after the Program 467 development efforts concluded, many members

of the programming staff and all the key members of the trajectory development

staff relocated to Univac’s offices in Sunnyvale or St. Paul or

left the company. Univac however continued to provide support at VAFB

to both the Titan IIIB and Titan IIID for many years. The final launch

of the Titan IIID occurred on November 17, 1982 and the final launch

of the Titan IIIB/Agena D occurred on February 11, 1987.

![]()

4.3 Steven Kloner, 1973-

So many things that went on, that one could write

volumes

I started with the old Education department in December 1973.

I had some great people to work with. Names at the time were Ken Boehm

(deceased), Gary Hagen, Dan Newton (Mgr), Don Kimball, Mr. Engelke,

Paul Burley, and of course many others. It was a great place to work.

We got the job done and even had fun along the way. I must say that

I appreciated the help and support that one received at the time.

One can even remember many of the things

learned. I can recall working on a topic that was part of something

listed in one of the items mentioned in the sample viewgraphs that you

provided was the 1652 Dual Display console. I did most of that work

at Air Force bases. What I did not realize at the time was that I was

doing state of the art graphics programming before it was common. That

was a real personal achievement. Now with all the PC’s and packages,

it’s not the big thing that it was at the time. Back then, one

had to actually code in assembly language to make that happen.

Looking at funny events along the way, and we all had our share of them,

makes me think of one in particular. I was conduction an AN/UYK-20 Programming

class at NUSC in New London, CT. (The facility is no longer there -

it has been torn down and replaced by a Pfizer facility.) Anyway, it

was a very busy week and Friday afternoon had finally arrived. Now in

those days, there were no CD’s or anything like that so we carried

all these technical documents with us. I was starting to summarize and

also pack up boxes of reference documents. Now we would tape these boxes

up, label them, take them to the airport with us and ship them along

with our checked baggage. Well anyway, I had just put these manuals

in a box, taped it up and was getting set to finish when a person raised

his hand. He asked this question with very serious look and with determination.

The question was “Does the UYK-20 have a Pie Cost? Well, when

you hear that, you think Pi (as in circumference stuff). Upon hearing

this – remember the look and the sound “Pi”, I started

checking. Well the first thing that came to mind was that they had recently

come out with the Math Pac option for the UYK-20 and I knew that there

were trigonometric functions in that. So with that in mind, I checked

the material that I had not packed and found nothing. Then I though

I better check in the big heavy UYK-20 hardware manual that was already

packed away. I cut the tape and opened the box, took the hardware manual

out and started searching. Well after 10 minutes, I could not find a

thing. Finally I had to ask, “What’s a Pi Cost?” The

fellow then says to me, going from a stern serious look to a smile “Three

dollars and forty-nine cents”. Well talk about hook, line and

sinker, that was me.

Inthe old Univac training department, one

of the classes taught was the Computer Fundamentals Class. We had a

Study Guide for use in the class and it was pretty good. In those days

it covered things like Octal and Hex numbering systems and also things

like logic blocks, i.e. AND, OR, XOR logic functions. The course was

five days in length most of the time. We had a variety of students in

the class. The students ranged from people from the assembly line in

old plant 1 to technicians, new engineers and people who were in administration

positions. We had a computer for this called the Univac Digital Trainer.

It could even be hooked up to some kind of Flex Writer. The computer

could let you input programs from the panel. Dan Newton, who was the

manager at the time worked on this before becoming manager. I have no

idea of what became of this computer but it would be interesting to

see it again. This digital trainer would be an historic item to locate

[Maybe it’s in a warehouse someplace?] Another item that we had

was a 16mm sound movie that was an introduction to computer fundamentals.

I think it ran between 25 and 30 minutes. I have no idea as to what

became of that film.

Another item of interest

was another movie. This movie was produced by one of the major television

networks and it involved a former employee of Univac. In 1976, I was

conducting an AN/UYK-20 Programming Course for customers from Japan.

These customers represented the Japanese Navy and various companies

i.e. Toshiba, Mitsubishi, etc. The Japanese naval representative requested

that time be allotted to view this documentary film. The film was a

story about a P-38 Lightning plane that was shot down in New Guinea

during World War II. The plan crashed in the jungle and the pilot was

found by the local natives. He was on the verge of death but the local

population nursed him back to health. He even returned in later years

to thank them. He was an employee of Univac later on. Don Lovely

would remember this story as he was involved and I believe he knew the

pilot involved. ![]()

4.4 Bruce Klugherz, 1959 - 1999

It is amazing to me that I am considered “an

old timer” to make a contribution to the history of the company.

Times have really changed. When I joined the company in 1959 I was part

of the Titan ICBM program. We used to attend meetings with other companies,

and we were always the youngest guys in the meeting. Funny thing, that

all changed by the time I retired in 1999.

I was fortunate to be part of the Titan Missile Project as part of Remington

Rand Univac. After some training in St. Paul I was assigned as Engineer

in Charge of one of the missile guidance systems at Cape Canaveral.

It was great to learn about missiles and guidance systems. The guys

from all the other companies were more than willing to teach you anything

you needed to know about their equipment, so you could do your job better.

As the years went by, companies who would some day be competitors were

not so willing to share information. As part of the ground guidance

team I had an opportunity to do something that not many people have

done. We were launching a special payload one day which included an

inflatable 100 ft. diameter aluminized balloon called ECHO. It was the

first communications satellite and you could bounce signals off of it.

The computer was supposed to send the signal to eject the payload but

the signal was not received by the missile. My job was to change the

computer controls from automatic to manual and then punch in the octal

code on the control console three times at five second intervals. Luckily

for me the signal was received and the payload was ejected and the balloon

was inflated. I received a joke award from our launch team called “The

Order of Digitis Extensionis”.

My

next assignment was to manage the installation and test of an operational

underground Titan Missile complex near Beale Air force Base in California.

Our team was requested to staff the Titan ground guidance system during

the Cuban Missile Crisis. We were all very relieved when the crisis

was ended and we were not required to fire the Titan missiles in response

to a Russian attack.

Upon return to St.

Paul I was assigned to work as a programmer and later as a manager of

the Automated Design Department. A programmer in those days worked in

machine code because compliers and high level languages were not yet

available. During this time of early 1963, Univac was far ahead of the

industry in the development of software for design automation. One of

the important software programs developed in this group was the wire

wrap router program. As computing speeds increased the designers required

the routing programs to take into consideration the shortest wire path

possible to transmit the digital signals.

My next assignment was to the Program Management office for the US Navy

S-3A anti submarine aircraft program. This was my first business relationship

with the Lockheed Martin Corporation. Little did I know that one day

I would become a Lockheed employee. I also worked as a Systems Engineering

manager in support of Avionics Programs. This work involved many challenging

new systems. Some of this work involved classified intelligence gathering

systems.

As a Systems Engineer I was also required to support the

Marketing Department on presentations to customers. It was at this time

that I also had to opportunity to participate in the generation of proposals

to the government customers. Writing proposals is a hard job but it

was great for building team spirit. Those were the days when we would

celebrate a win with a gathering of those involved on a project to enjoy

a barbeque and sweet corn picnic at the lake. Oh yes, there may have

been some beverages served also. After a few beverages had been consumed,

there would always be a round of singing which included the song ANEW

We Love You. This song was a parody to recognize all of the contracts

we had received over the years from the US Navy for hardware and software

produced in support of the Lockheed P-3-C aircraft.

In the later years of my career I mostly worked in Program Management

on a number of different programs. There are two programs that have

many memories associated with them. Those programs were the 6977 Communications

program for the Government of Israel and the Q-70 computer and display

program for the US Navy.

A part of the program

management team, I worked on the 6977 program. It was one of the first

international programs won by Univac. This program involved subcontracts

with companies from Israel, Italy, and several US companies. This program

was a learning program for our company. Doing business with foreign

companies has many challenges above and beyond the language issues.

The system got installed and as far as we know is still achieving all

of its objectives. This program did result in a two year international

arbitration of a contract dispute. Participating in the court proceedings

was a lesson in business practice. As I learned, you cannot avoid a

contract dispute in the way you write your business memos, but if you

take the time to ensure that the business memos truly say what you intend

to say, you can avoid multiple interpretations of your words at a later

time.

One of most memorable programs was the Q-70 program for the Navy.

This program was the first time that the US Navy decided to make use

of commercial off the shelf hardware (COTS). Until this point in time

all of the computer and display parts were ruggedized special design

and the software was written in a special Navy software language called

CMS-2. It was also true that for many years Univac had been the Navy

supplier of computers, and Hughes had been the supplier of the CRT displays

that were connected to the computers. Top management in St. Paul was

not at first willing to fund a proposal effort that would promise to

build a hardware and display system, since it was assumed that only

Hughes could win the competition. After several presentations to Univac

management, we were given permission to bid the Q-70 program, and we

were extremely happy when we won the competition. That program has been

a major business area for the company over the past several years.

In the last years of my career, I worked as a program manager on

several programs. I am glad to say that one of those programs was the

newest most modern class of submarines called the Virginia Class. This

program gave our company experience in some of the most technology challenging

communications systems available. The once Silent Service, has now become

an integral part of almost every military operation of our military

service.

Our company has changed a lot over the years, but one thing

has not changed, and that is the many good people who have contributed

to the company success.

![]()

4.5 Dave Kolling, 1958 - 1994

REFLECTIONS ON MY CAREER WITH UNIVAC

After graduating from Mankato State College in 1958 with a degree in

Math and Physics, I was hired by Remington Rand Univac (RRU) as a Programmer.

I didn’t really know what a computer was so I was scheduled to

attend the infamous Dr. Brown’s digital computer logic class.

Besides learning about computer gates, it was my first exposure to the

binary and octal number systems. What an eye opening experience.

My first assignment was working on the Threat Evaluation & Weapon

Assignment (TEWA) module for the Service Test version of the Naval Tactical

Data System (NTDS). The strategy and mathematics for this “shoot-look-shoot”

philosophy was developed by Dr. Alex Radcliffe at the Johns Hopkins

University-Applied Physics Laboratory. It was a pioneering effort to

automate this function on board naval ships.

This was just one of many “firsts” developed for the three

Service Test ships during the early 1960s. Some of the others included

the first production solid state digital computer (AN/USQ-20), the real-time

operational software executive which allowed asynchronous operation

and automatic computing load balancing, automated intercept control

and automatic radar/target tracking. It was this latter capability,

developed by RRU, which led to the awarding of the first Air Traffic

Control contract and a long and successful association with the Federal

Aviation Agency (FAA). Through all of this, we emerged as the unofficial

system contactor for all subsequent NTDS variations and implementations.

The programming that we did was originally in absolute code, written

in octal numbers and punched in paper tape to be read into the computer.

This being very inefficient, led to our development of the R-3 Assembler

(which allowed relative addressing) and then the CS-1 Compiler which

allowed the programs to be written in English language logic statements.

This made it much easier to develop operational programs that would

exceed the 32K of 30 bit memory that was available in each computer.

After the original service test software was

ready in the early 60’s, Univac assisted the U.S. Navy in establishing

the Fleet Computer Programming Center, Pacific (FCPC, Pac)in San Diego.

Their responsibility evolved into that of developing the “official”

operational software since this was something that could not be done

by a private company since it involved devising and implementing naval

strategic and tactical doctrine. In essence, UNIVAC became the proof

of concept and prototype system developer and FCPC, Pac became the production

developer.

UNIVAC also pioneered the use of computers

to evaluate the actual installation and integration of NTDS shipboard

systems. This was accomplished with specific test software programs

developed for each piece of equipment, diagnostic programs for the computers,

Programmed Operational and Functional Appraisal (POFA) programs for

each piece of equipment interfacing with the computer and Integrated

Programmed Operational and Functional Appraisal (IPOFA) programs to

test the overall installation. This software turned out to be very instrumental

in the quality of system installation ultimately achieved by the shipyards.

During the late 1960’s, we were contracted

by the Navy to develop a specification for the process of software development

that became affectionately known as “SHIPS 0011,” an abbreviation

of the official specification number. This document addresses the entire

development process from developing the functional requirements, through

design specifications, programming and software testing. The specification

has evolved over time and became a Navy wide standard. This also led

to Univac developing the software quality specification that was used

Navy-wide for subsequent software procurements.

Because of the significant R&D that was being conducted by Univac,

the U.S. Navy created a digital computer combat system integration and

test center at Mare Island Naval Shipyard in Vallejo, Ca. It was at

this facility that the cutting edge digital technologies for digital

fire control and automatic radar control for detection and tracking

were proven to be viable prior to implementation in the fleet. The digital

closed loop control of the fire control radar, rather than the previously

accepted analog control, really opened the door to the eventual domination

of the digital computer in all of the combat system functions.

The Univac 1218 and 1219 18-bit computers became standard for the Naval

Weapons Systems Command for the digital replacement of the older analog

fire control computers for the Tartar, Terrier, and Talos missile systems.

Digital control of the AN/SPS-48 radar beam for detection and tracking

heralded a new concept of radar. T his eventually led to development

of the Aegis phased array radar system that is the mainstay in today’s

fleet.

The 1218 computer was also the heart of

the AN/SPN-42 Automatic Carrier Landing System that was developed by

Univac in conjunction with Bell Aero-Systems who had developed the original

analog system. This system was eventually deployed on all of the active

aircraft carriers.

The next major technology

breakthrough was in the early 1970s, the development of the AN/UYK-7

computer, the first computer with multi-processing capability. The first

operational implementation of this capability was in a two bay/dual

processor configuration on the SSN 688 (Los Angeles) class submarines.

Closely following was a four bay/triple processor configuration implemented

on the DLGN 38 class surface ships. The key advancement was the systems

tolerance to hardware failures. The system would automatically detect

the failure, isolate the failed component and adjust the computational

load until it could be removed and repaired.

This computer architecture rapidly became the standard for several offshoot

computer architectures that were used by the U.S. Marine Corps in their

tactical air control and command center shelters as well as the Apollo

program for their satellite tracking. The last major Mil-Spec computer

developments were the 16-bit AN/UYK-44 and 32-bit AN/UYK-43 computers.

Both of these production contracts were won by Univac in 1983 after

competitive development runoffs against IBM. These computers really

marked the end off the “bullet-proof” Mil-Spec computers,

for from that point on, the military’s hardware procurement emphasis

switched to utilizing commercial off-the-shelf components and open architecture

concepts as much as possible.

During the foregoing

time period, I was personally involved in these technology advancements

either from a Systems Engineering or Program Management standpoint since

I spent about equal amounts of time in both functional organizations.

Probably the most challenging assignment I had during my career was

first as Program Director for Eagan’s combat system software development

for the Canadian Patrol Frigates (CPF) and my subsequent transfer to

Montreal, Canada, from 1988 - 92 as the Program Director for the overall

program at Sperry/Unisys Paramax division. CPF was a major $2.4B system

development and management contact that required Sperry/Unisys to design,

develop, procure, install and test all of the electronics for the combat

system and machinery control systems for 12 patrol frigate class ships.

The contract started in 1983 and completed in 1996 with delivery of

the 12th ship. The first frigate was delivered to the Canadian Naval

Forces and commissioned in time for it to be deployed as the centerpiece

of Canada’s commitment to the first Gulf war coalition forces.

The CPF was significant in that it featured 33

computers networked on a SHINPADS data bus, working in a shared processing

environment that was completely fail-safe. The ASW and AAW modes of

operation were also capable of being controlled manually, semi-automatically

or fully automatically. This was the first warship that had these features

operationally implemented.

In 1986, Burroughs

purchased Sperry and Unisys emerged from behind the white curtain. Unfortunately,

this was the beginning of end of the legacy of UNIVAC as we all grew

to know and honor over the years - a legacy of leading edge technological

innovation and customer satisfaction. Fortunately, I had the pleasure

of working at UNIVAC during the “Glory Years,” starting

my career as a programmer in 1958 and retiring as Vice President, Engineering

in 1994. It was a great ride!

![]()

4.6 Tom Kratz, 1965-

I joined UNIVAC in 1965 right out of College,

newly married, and ready to jump into this unknown new computer business

area. Fortunately, I had taken the only computer course available before

graduation; Fortran on an IBM 1620 using punch cards for the program

instructions and data.

After a few weeks of training

in St Paul on a programming language called CS-1, our little group of

8 new hires [including Tom Hanson, Tom Rougier, Lyle Olson, Dean Sandifer,

Roger Parker, et. al.] were transferred to Willow Grove PA to work on

a new project called ANEW. ANEW was the US Navy’s attempt to put

a digital computer on a Lockheed P-3-C to provide anti-submarine warfare

operational capabilities. Initially, we had a 32K computer with flight

testing being done out of Patuxent River MD.

In

1968, I followed the evolving ANEW project out to Burbank where Lockheed,

as prime, had the aircraft and a full laboratory mock-up for program

development and system checkout. It was the type of project where the

team was working 60-70 hrs a week for over a year; but the pay was good.

After working in front of the computer console for so long, one could

just look at the instruction execution light patterns and say if the

program was running normally. It still amazes me the extent to which

we programmers had to intimately know the computer architecture and

instruction execution details to develop programs successfully in those

days. Today’s normal SW engineer cannot fathom that HW/SW relationship.

Being a part of the Lockheed flight test crew, one had to endure 10-hr

long-range navigation test flights, MAD equipment alignment test flights

which also tested who had a steel stomach and tactical ASW fights flying

100-200 feet above the ocean. One flight experience sticks with me.

We were on a long inertial navigation accuracy test flight over the

Mojave Desert when the airplane hit an air pocket. I occasionally stood

behind the pilot looking out the cockpit to pass time. When the plane

hit the air pocket, I went up or the plane went down resulting in my

head jammed up into a metal part of the escape hatch. The blood was

flowing down my face and the flight was aborted to return quickly to

Burbank for some medical attention. What an exciting time for a guy

from Minnesota. It was a time of real job satisfaction.

P-3C [starting with ANEW] turned out to be one of the longest running

projects the company had, not only with the USN but with several other

world Navies.

My experience on the P-3C 1830A

computer brought me an offer to work on the German Fast Patrol Boat

Project, which used the 1830B (shipboard version) computer. In 1971,

my family and I transferred to the Netherlands where Signaal Co. (Prime

contractor) was responsible for systems and software development. The

development team, made up of Americans, Germans, French and Dutch, moved

to Wilhelmshaven, Germany to complete the effort. Some of the American

team included Lowell Benson, Bill Rogers, Dennis Christ, John Rachac,

and Jim Gannon. Being a multi-national project, we Americans were lucky

that both the work environment language and the social [party] language

was English. That made life relatively easy but, regrettably, did not

force me to learn German better than I did. My wife and I have maintained

relations with many of these early acquaintances to this day.

This started a 33 year long relationship with international business.

I joined the international Program Management group around 1977 thanks

to encouragement from Dennis Christ. Although my primary business area

was with Germany, over the years I managed contracts with Canada, UK,

France, Spain, Greece, NATO, Norway, and Italy. Visiting these customers

allowed me to travel throughout most of Europe during the best of times.

Besides the Fast Patrol Boat, other major German Projects included Frigate

122 (8 ships), Frigate 123 (4), Minehunter 343 (6). By the late ‘90s,

Europe and Germany adopted the strategy that, with the availability

of COTS equipment, system development could be done by their national

defense contractors allowing defense spending to remain more within

Europe. We lost the competitive Frigate 124 contract in 1998 mostly

because of that and that loss started the downward spiral for the Lockheed

Martin German business area. Since the time of the Fast Patrol Boat

project, St Paul always had a branch/marketing office in the Bonn area

handling the direct customer marketing interface and taking the prime

contract on behalf of St. Paul. Some of the notable Bonn office Managers

included Lee Dominick, Gary Holthusen, Gary Humfelt, Chuck Hammond,

Dennis Christ, and Manfred Wiese. Prior to Wiese taking the lead position,

St Paul always had an American heading up the Bonn office rotating every

2-4 years.

For years, John Byrne was the St Paul

international marketing man. John and I pursued many international opportunities

(business) together. Having Don Blattie normally as the international

contracts manager, made for many smooth running programs and Senior

Management expected international programs to provide good margins for

the Company. Not having exact figures, I would say the Japanese business

area, run by Bob Pagac, was the only business area that produced better

margins than Germany, over time. Over the years, I have had great bosses

including Dennis Christ, Bob Alexander, Bruce Grewenow, and Doug Schmitt.

In closing, it was a very good ride. I always

enjoyed going to work, which also means I enjoyed the people with whom

I worked.

![]()

4.7 Dick Kuhns, 1960 - 2000

I started to work with Remington Rand Univac (RRU)

in June 1960 after receiving an electrical engineering degree from South

Dakota State University. My first year at RRU was spent in the component

test lab in Plant 2 and writing hardware specifications. Working in

1960 at plant 2, which was a converted glider factory from WW II [and

the original home of ERA], was an experience. We covered our desks with

paper when leaving each day to keep the sparrows off the desk.

In 1961 I transferred into the Navy Systems Engineering department.

Approximately 25 of my 40 years with the company were focused on Navy

projects. It was an exciting and interesting time to be part of the

continued development of NTDS. When I started, NTDS had already been

introduced and tested on its first group of ships. In the early 60’s,

I developed software for equipment test programs, system interface tests,

and Radar Alignment and Designation Accuracy Tests (RADAT). These programs

were initially tested at the Mare Island Naval Shipyard test site. This

was a great time to be an engineer and software developer. The projects

at Mare Island were focused on doing things with digital computers that

had not been done before - automating command and control functions,

automating radar processing, and establishing digital interfaces between

NTDS, radars and Fire Control Systems. Once the RADAT software was ready,

I took the test aboard all of the ships in the CG26/28 class (CG26-35)

and three aircraft carriers to test the alignment of all of the search

radars with the fire control radars.

I’ll

never forget my first trip at sea on board CG 26, the USS Belknap. Before

the ship sailed I was playing around with the test software at a display

console not realizing that my balltab (cursor) was directly connected

to the massive multi-ton fire control radar. As I moved the symbol from

one side of the display screen to the other side (i. e., violent sudden

changes in bearing) there would be a whooshing sound and the ship would

vibrate. After a minute or two a young fellow came up to me in a hurry

and said “Whatever you are doing stop!!!” Apparently my

designations through the system were being accepted directly with no

damping or smoothing. The necessary controls were put into the system

so the problem went away.

As the ship sailed

from the pier at the Bath Iron Works in Bath Maine, I was inhaling tomato

goulash in the officer’s dining room not realizing that once out

on the ocean it would be a bit wavy. My first experience with sea sickness

was unforgettable. When the ship returned three days later my first

task on landing at the pier, after putting my feet on solid ground,

was to call CDR Boslaugh (When Computers Went To Sea) and Jim Mountain

for whom I worked at the time. It was a new experience for them to send

a young programmer out to sea so they were interested in a report. The

experience gained from these trips at sea gave me a great appreciation

for the magnitude and complexity of the electronic systems on board

ship.

In the late 60’s I left software test

development and focused on system studies and hardware interface development.

One of my projects was to manage studies and prototype development for

the NTDS serial Input/Output (I/O) interface. It seems a bit unusual

now, but at the time sending digital information over one wire was considered

to be heresy by some people. Cmdr Drenkard was the Navy project officer

supporting the studies and held fast to pushing for a serial I/O interface

over one coaxial cable wire. During the development of the serial interface

I read and adopted some of the interface philosophy defined by Dave

Lundstrom (A Few Good Men from Univac) who left behind a number of I/O

white papers when he left the company for CDC. Dave was considered to

be the I/O expert for the development of the original NTDS interfaces.

The result of these studies and prototype efforts resulted in the specification

of the NTDS Serial Interface {Editor's note: This

serial interface became MIL-STD-1397 Type D, preceding the later Low

Level Serial.}

Before leaving the

1960’s I would like to say something about the way work was performed.

The 60’s can be characterized as a time “before PCs" and “before

copy machines”. Our secretaries would type all of our documents

usually with carbon paper. If we wanted something copied in Plant 5

we would go to the ozalid room for copies. In the early 60’s I

would be debugging my software programs late at night in plant 5. All

direct computer work was performed at the computer front panel in binary.

Software would be compiled on the target machine and punched on paper

tape. If the punch would erroneously punch the wrong holes, the whole

process would be repeated. Work energy was high both in St. Paul and

at Mare Island. After work hours in St. Paul, there were many intramural

sports. I particularly enjoyed fast pitch softball (slow pitch had not

been introduced yet) with Hank Zelenka as our pitcher. Everybody worked

hard and played hard. Work hours at the Mare Island Naval Shipyard were

scheduled 24 hours per day so it was not unusual to be assigned work

time at night. I remember getting a speeding ticket late one night for

exceeding the 10-mile per hour limit.

I worked

with the Navy to define the requirements for the Data Exchange Auxiliary

Console (DEAC) during 1969 and then carried the project through the

pre-proposal and proposal stages as the proposal manager. The DEAC became

the primary auxiliary interface for keyboard/printer, paper tape reader/punch

and magnetic tape interface during the 70’s and 80’s.

The Junior Participating Tactical Data System (JPTDS) system development

started in the early 70’s. I was the project engineer for the

JPTDS as well as some related hardware system developments. The JPTDS

was ultimately installed on the DDG-2 class of ships. Part of the JPTDS

contract required the installation of a small JPTDS system in a forty-foot

trailer that could be moved to various locations. Once completed the

trailer system was located at Mare Island where it supported testing.

The system installed in the trailer used the NTDS Serial Interface for

the first time. One of the Magnetic Tape Transport’s (MTT’s)

was removed from the DEAC and replaced with a small analog to digital

converter [Integrated Circuit KCMX] to enable the input of ship motion

synchro data. The trailer also contained either the first or second

UYK-7 built so it became a test bed for new hardware concepts. The JPTDS

contract work was initially performed under the overall direction of

CMDR Campbell followed by CMDR Crandall. During the development of JPTDS

the navy was promoting the system and the UYK-7 to foreign navies. On

a number of occasions I would accompany the Navy and company marketing

representatives on international trips to give presentations on the

system.

A large variety of system studies and

proposals were generated during the 70’s, dealing with the application

of digital computers to shipboard systems. One of the study efforts

resulted in the definition and implementation of the Shipboard Integrated

and Processing System Serial Data Bus (SHINPADS SDB). The study effort

for the SDB started in 1976. Prior to 1976, we had been actively involved

in distributed processing IR&D studies. Gene McCarthy from the Marketing

department had established a relationship with the Canadian Navy and

was instrumental in winning a study contract for defining the SHINPADS

SDB. Gene setup a good working relationship between the Canadian Navy’s

CMDR Carruthers and their engineering. CMDR Carruthers was a primary

proponent of developing a distributed Naval Combat System architecture

having a large number of computers interconnected with a serial data

bus. CMDR Carruthers wanted to stay close with our engineering activity

directed at the definition and development of the SDB since it was key

to the ultimate success of SHINPADS. As a result, CDR Carruthers would

call frequently to discuss distributed system philosophy and the status

of the SDB development.

The SDB proceeded from

definition, prototype development, testing and many demonstrations to

a final specification for the interface. These efforts were spread over

a time period of about 3 years with many presentations and meetings

to discuss the feasibility of implementing a distributed processing

system with the SDB. A description of SHINPADS and the SDB was presented

at the 1979 American Society of Naval Engineers (ASNE) annual symposium

and published in the April 1979 Naval Engineers Journal. [1. Carruthers,

J. F. CDR Canadian Forces, SHINPADS-A New Ship Integration Concept and

2. Kuhns, R. C. Sperry Univac, The SHINPADS Serial Data Bus]

The 80’s were spent in various management positions coordinating

system studies, proposal development, IR&D projects. I spent a few

years working on a Master of Science in Software Engineering from the

University of St. Thomas-finally earning the degree in 1988.

For three years in the early 90’s, I was the Project Engineer

on a classified project located in Camarillo, California (two plus years)

and then back in Minnesota for the final few months.

After returning from California I took a temporary assignment with the

UNISYS World Trade Division where I was the Site Manager in Vienna,

Austria for a few months and readied the project for transfer to Prague

and then was the Development Manager in Prague, Czech Republic on a

commercial banking system development. The total length of the European

assignment was 14 months. One of the chief challenges of this project

was directing the work of over 30 people from 7 different countries

with all but two of the people being sub-contract programmers. One of

the programmers on the project was from Slovakia and did not speak English.

Another programmer was from Russia and lost his visa suddenly in Prague

and was not allowed to stay in the country. I missed the services one

would normally expect in a large company environment.

After returning from Europe I worked for Larry Huff where I initially

managed new technology studies for the UYQ-70 Display System and then

managed a Communications business development group and Communications

IR&D project until I retired in 2000.

My focus

over 40 years with the same company, starting with Remington Rand Univac

and ending with Lockheed Martin with several company name changes in

between, was on software development, system engineering, marketing

support, and engineering management. Changes to the work environment

before PCs and after the introduction of PCs were dramatic as were changes