Information Technology (IT) Pioneers

Retirees and former employees of Unisys, Lockheed Martin, and their heritage companies

People G-H, Chapter 13

1. Topical Article Contributions:

Thirty people have contributed 60 technical articles or tidbits - also, see Legacy, Our Stories chapter.

- Bill Galle, Art Gehing, Bill Geiger, Millie Gignac, Lyle Gilbertson, Harry Goldbacher, Alan Goldstein, John Gould, Ken Graber, Lee Granberg, George T. Gray, and Bob Grueschow.

- Chuck Halls, Glen Hambleton, Ron Handy, Fred Hargesheimer, Quint Heckert, Al Heiden, Carroll Hershey, Bradley Hinman, Curt Hogenson,

- Dieter Hoffmann, Gary Hokenson, Lee Holck, Chuck Homan, James A. Howe, Ned Hunter, Bruce Hyslop, and Jim Hyslop.

2. Career Summaries - G:

2.1 Bill Geiger, (1959-90)

Shortly after graduating from North Dakota

State University with a BSEE I joined Remington Rand Univac as a

member of a new recruit class of “double E’s“ and math/science

majors numbering in excess of twenty in June 1959. I had previously

attended the University of North Dakota receiving a BSC in Marketing

in 1953 followed by work at Goodyear Tire & Rubber as a District

Sales staff man doing sales promotion, statistical analysis and

advertising and in the Air Force as a communications

intelligence officer.

Our initial indoctrination to Remington Rand

UNIVAC took place at the training facility on Ford Parkway where we

became familiar with a new (to us) version of math involving octal

notation and binary numbers, among other things, as well as

fundamentals of programming. One characterization of engineers and

programmers at that time was that virtually all of us wore pocket

protectors well stocked with pens and pencils. We were not quite out

of the slide rule era. You would likely see a Freiden calculator as

a common fixture on engineers’ desks as opposed to the PC you would

see on engineers’ desks today. Lunchtime games frequently played

included “Go”, a game of Oriental origins that math majors liked.

The Journal of Mathematics was not an uncommon on sight. A new

language of the programmer seemed to becoming more commonplace.

My first assignment was of short duration in developing

plans and programs for TEWA (another new term meaning Threat Evaluation

and Weapons Assignment) where several of us were involved with personnel

from the Applied Physics Lab of Johns Hopkins University who were under

contract with the Navy’s Bureau of Weapons on the Navy “Three

T Program" (Terrier, Tarter, and Talos missile systems.) Within the

year I was assigned to perform analysis of the NTDS Service Test display

system (Hughes Aircraft developed), its use in weapon assignment functions,

and to develop USQ-20 computer programs (machine or absolute code) and

procedures for test of the display subsystem as well as the UNIVAC-developed

Video Processor and programs to assist in aligning and calibrating various

shipboard sensors. These tests were performed at the Naval Electronics

Lab in San Diego where sizeable cadres of Univac programming personnel

were located onsite housed in the adjacent barracks area to support

early NTDS program development.

The Navy followed up NTDS Service Test by establishing

the Fleet Computer Programming Center Pacific in San Diego which UNIVAC

provided major support for with several hundred software development

personnel located onsite at the FCPCP facility adjacent to the Navy

Electronics Laboratory and in nearby offices. These personnel later

became heavily involved in the development of the B-2 program for an

automated shipboard tactical data system for the Federal Republic of

Germany with a test site within our San Diego facility and also programs

for the Marine Corps Aircraft Landing System (MATCALS). I think it is

interesting to note that the Navy chose an officer of Chinese descent,

CDR Ming Chang, as the project manager for this German program. He was

later to become the first naturalized Chinese to attain the rank of

admiral in the U.S. Navy and I believe became the Navy Inspector General.

The integration of the various NTDS shipboard equipments

required an extensive system of tests of individual equipments as well

as their operation when functioning within the entire system complex.

A series of programs termed POFA/IPOFA (Integrated Programmed Operational

and Functional Analysis) were Univac-developed and greatly assisted

the Navy in proving the overall functionality of NTDS equipment and

in their integration into operating subsystems and systems. Weapon Direction

System Mk 11 was the next extension of NTDS incorporating closer ties

with the fire control radar and missile launcher which had previously

been controlled by analog computers. Mk 11 integrated the fire control

function into NTDS providing, to the best of our knowledge, the first

digital closed loop control system for large electro-mechanical systems

such as the shipboard missile system radar director and the missile

launcher. Launcher control (load, fire, etc.) was provided by a UNIVAC-developed

Weapon Control Panel. Interface with the analog radar director and launcher

was provided by analog-to-digital and digital-to-analog converters in

the Fire Control Data Converter also developed by Univac in conjunction

with our subcontractor, Ford Instrument Company, a sister division within

the Sperry Corporation. The radar director and previously employed analog

fire control computers were built by another Sperry Corporation Division.

With the experience gained in the development and integration

of computers and associated equipment, operational and test programs

for NTDS as well as for the Navy’s ANEW program for the P-3C ASW

Surveillance aircraft, the division extended its systems activities

into Air Traffic Control (ARTS III), SPN-10/42 Automated Carrier Landing

Systems, Marine tactical systems (MATCALS), Canadian Patrol Frigate,

attack (SSN 688) submarine systems and a number of U.S. and international

military surface, airborne and submarine programs. Major proposal efforts

were conducted on a number of surface, subsurface and airborne tactical

and surveillance programs, including the Navy’s DXGN and ASMS

programs partnered with major platform and weapons systems contractors.

The position of being the supplier of the computer system on many of

these programs gave us a unique advantage to pursue major system roles.

A number of other U.S. military or government programs employed computers

following the development of the USQ-20, including the Trident/Polaris

Navigation System, NASA Shipboard Telemetry System, Minuteman Missile

System, cruise missile communications and the USAF Wild Weasel program

among others. A number of significant new technologies were employed

in some of these systems including thin film and wire memories, touch

screen operator input capability, and fiber optic communications.

Following involvement in Mk 11 and POFA/IPOFA testing,

my association with programs and projects evolved more into organizational

and program management functions including system and design engineering,

marketing, program management and general administration. In the early

'70s I was asked to serve on a NATO Industrial Advisory Committee led

by U.S. Navy personnel and comprising civilian representatives from

the UK, Italy, France, Netherlands, Federal Republic of Germany, and

the U.S. Naval Research Lab. The objective of this committee was to

examine how interoperability could be achieved between NATO Navies and

their ships. This activity was extremely interesting to see the interplay

between individuals from various countries, each with his own ideas

and experience as well as nationalistic views, participate in the development

of a common approach to achieve interoperability. Capt Eric Swenson

was a prime mover for this committee and the work it undertook. He was

also an avid railroad fan and as a result, our travel throughout Europe

on quarterly trips was almost entirely by train. It was his objective

to ride as many of the world's train routes as possible. Travel in Europe

proved to be interesting to say the least. On passing through cities

on our route at any time of day or night, Capt. Swenson would get off

the train even at the very briefest stops to take pictures of the station

name for his record. One journey from Rome to Boulogne, France, on Palm

Sunday weekend, 1975, was particularly memorable because we had to stand

for almost the entire trip due to holiday crowds and lack of seating.

Capt. Swenson was a friend and just one of many highly qualified Navy

officers and personnel who we had the privilege to work with on a number

of programs.

As program manager on a number of key programs, responsibility

fell on me as well as others to meet with key Navy personnel when problems

were encountered. There was a period when the UYK-7 computer was suffering

from a combination of performance/reliability issues complicated by

questionable Navy maintenance. Weekly meetings with Admiral Wayne Meyers

were required at his insistence. He could do a very good job of admonishing

UNIVAC as well as any other AEGIS contractor for their failure or the

failure of their equipment to meet his expectations, which were often

very high. He would routinely sit back in his chair with his feet propped

up on his desk and “blast away.” He had one interesting

admonition for the Navy itself which I had never heard from other Navy

personnel. When he heard his ships referred to as “vessels”

he was upset. He was heard to state that “vessels” were

pots you put under your bed with an obvious purpose. I wonder if the

Navy will take this position into consideration when they christen the

DDG-108 in his name.

There were many other “interesting” occasions

involving meetings with key Navy personnel. During early days in production

of the UYK-20 the Navy was insisting on a very extended and extensive

burn-in test procedure before acceptance. I participated in the negotiations

for this procedure which took place with Capt. Chuck Hager and were

extremely long and difficult to say the least. The test that resulted

was one of the most extensive, long term test programs for any piece

of Navy procured electronic equipment up to that time. Fortunately,

our factory and engineering personnel proved that they and the UYK-20

were up to the task.

The 30 years I spent in the employ of and at many levels

and in many capacities within Remington Rand Univac, Sperry Rand Univac,

Sperry Univac and Unisys were years that I treasure. The people I worked

with were almost universally people I had the very greatest respect

for in terms of their ethics, intelligence, talent, and perseverance.

As individuals they routinely demonstrated a total commitment to their

work and to the goal of making Univac products and services successful,

whether the output was a proposal, a computer program, a computer or

other electronic system. They had a work ethic that was unmatched in

my observance working with personnel from a good number of other companies

and countries. I believe our customers recognized this and as a result

we had a great deal of follow-on business from a number of customers.

I have many memories of individuals who were outstanding in performing

all sorts of jobs whether they were in technical or administrative functions.

I am proud to have worked with so many great people.

When I told my employment counselor at North Dakota State

University in the spring of 1959 that I had accepted a job with Remington

Rand Univac Military Division he made comments implying that this was

equivalent to taking a job with the post office – routine work

but not offering great opportunity. Many times I have thought that I

would like to go back and tell him how very wrong he was.

2.2 Millie Gignac, March 1956 to April 1986.

I started with Remington Rand Univac on March

26, 1956, as a clerk in the Payroll Department. This was in Plant

2 on Minnehaha Avenue, St. Paul. I was soon promoted to the job as secretary

to the Director of Financial Control, and soon was very active in the

Company's United Fund Drive (for several years), the Company golf tournament

and was very involved for a number of years with the selection of the

Company's Winter Carnival princess. During this activity, I worked closely

with the Public Relations Department.

In 1962 I was transferred to the position of secretary to the Personnel

Director and in 1966 was promoted to Group Leader in the Personnel Department.

After that I became Supervisor of Records and Benefits. I transferred

to the Corporate Office in Blue Bell in 1969 as a Employee Information

Specialist, and in 1972 was promoted to Supervisor of Benefits Research

and Administration. The following year, I was made a Manager and provided

functional direction to all the Operating Divisions Personnel Departments,

with respect to group insurance and retirement programs.

I was transferred back to St. Paul in 1974 as Manager of

Pre-Retirement Counseling for the Twin City Operations. I was promoted

to Manager of Administration in the Resources Group in Defense Systems

in 1975, and while in that job, started planning (in 1979) for a 'retiree

club' and a clubroom for retirees. We cut the ribbon on the clubroom

in July 1980 and had our first general meeting in September of that

year. We elected officers, made plans for monthly meetings and rules

were drawn up. The VIP Club was born! [Editor's note: The first

VIP Club president was Al Mueller, retired manager of the Antenna Coupler

Department.] I promoted volunteerism to the retirees and soon became

a volunteer myself.

In October 1980 I was promoted to Director, Administration

and Benefits and was thrilled to be the first female in Univac Twin

Cities Operations to hold a Director title.

I retired April 1, 1986 after 30 good years of employment with a good

company. I am still very involved in volunteerism and find it one of

the most rewarding and enjoyable things I have ever done. I've published

my life history in a book and had a stamp created with my photo.

2.3 Jay Gildemeister, 1984-1989, part of 1992, then 1997-2008

After spending many years in the Navy, I

was hired by Raytheon Service Company in 1977 to certify SONAR and Combat

Systems equipments on the DD963 and DDG 993 Class Destroyers in Pascagoula,

MS. I had run into the Sperry field engineering teams in my Navy days

when commissioning the USS Virginia (CGN-38) and the USS Jesse L. Brown

(DE 1089) but never had the appreciation for the teams until working

at Ingalls Shipyard in Mississippi. One of the reasons I came to Sperry

after Raytheon and CACI, was the team of Combat System Field Engineers

(at that time run by Pat Casey). In my opinion, that group of personnel

was the finest group of customer service representatives ever established

to support the Navy. I can recount many stories of problems during construction

and testing where company reps (Raytheon, Honeywell, GE, etc.) were

called in to solve problems. The Sperry guys would come aboard, check

out the UYKs, determine the problem wasn’t theirs, and then “Fix

the Problem” regardless if it was a Radar, Fire Control or Weapon

System. To bad they were disbanded a few years after my arrival at Sperry.

I was hired into the Sperry Systems Assurance Department

in September of 1984. Interesting part of that story was a memorable

evening at Vogie’s with Billy Mitchell and Pat Casey prior to

my interview the next day. It made that day of questions and answers

difficult to say the least. Thank God for lunch at the Chart House where

I corrected my chemical imbalances. Regardless, I was hired initially

to write technical manuals for the Undersea Systems organization. In

late 1984, I was transferred over the System Integration and Test Department

to work the Royal Australian Navy (RAN DDG) program. I assisted System

Engineering Services, worked with C3 Pty Limited and NAVSEA to identify

and correct deficiencies. It was during this period of time that I had

some of my most interesting and fun times with people like Will Roberts,

Paul Hove, Dave Kolling, John Fritz, Larry Debelak, Jim Bougie,

John Lenvik, Jim Wikoff, Dave Bohne, and Rick Stevens.

I began to contribute more and more to program new business

efforts like ASWOC C3, NAS, MK53 A/C, NUWES and ABCCC. The MK 53 reminds

me of Jim Stage. Someone should ask him if he is still upset about having

his tie “scissored” at Pinnacle Peak in San Diego. In early

1987 I transferred to Unisys Systems Development. That involved the

Canadian Patrol Frigate (CPF) program and working with the Paramax team

in Montreal. Other programs worked during this time involved FDDS, ATACC,

SSN-21, CCS MK 2 and Lamps MK3 supporting Undersea Systems and Airborne

ASW programs.

One of the last programs I worked in 1989 before my leaving Unisys,

was the start of the NSA/NSH program proposal in Ottawa. I then left

Unisys and worked as an independent contractor and consultant from 1989

to 1992. One of the major programs worked during that time frame was

the Merlin Helicopter Program in Owego, NY for IBM Federal Systems (now

LM Systems Integration). That involved the proposal effort and upon

winning, over one year in the UK supporting the program start-up. One

evening while relaxing in Owego, Paul Flagg approached me about a position

at Paramax on the NSA/NSH program in Montreal as it had finally been

won. I accepted and worked on the Program Management Team until its

cancellation by the new Canadian Prime Minister the day after his election.

This led to more travel and employment with Bell Textron

Marine, Litton Data Systems and Boeing Rocketdyne back down on the Gulf

Coast until accepting a job offer in 1997 with Lockheed Martin Tactical

Defense Systems back in Eagan. It was interesting to note at that time

I could not retain any of my prior service for vacation and benefits,

however I was given the very same employee number that I had over 8

years before. Bob Dewey hired me into the logistics organization to

author and lead the ILS portion of the Q-70 Recompete Proposal. After

winning and working the program for a few years, I was asked to help

out on P-3 Programs. I primarily was involved with new business development

and worked multiple programs (AIP, Brazil, Korea, New Zealand, Pakistan,

Portugal, and Taiwan). More great people were met such as Herb Baker,

Teresa Hennes, Bruce Olsen, Dick Fuhrman, Bob Pagac,

Jim Conn, Tom Cegla, and Kenny Norstrem to name a few.

Recently I have supported multiple LM business units (Aero/IS&GS,

SI, etc.) developing technical approaches and proposals for programs

such as AMF JTRS, Deepwater, BAMS, HFTS, Presidential Helicopter and

PMRF. The logistics organization is now called Global Sustainment. That

name is probably better than some of our last names, i.e. Transportation

Services, however I have not yet figured out how to sustain the globe.

As I am preparing this it is approaching 2008 and I will

pretty soon cease supporting all the other retirees’ pension plans

and truly become part of the VIP club as a retiree. It has been and

still is (for the most part) been a great ride. You may have noticed

I mentioned a lot of people by name. Many more former and current personnel

could have been mentioned. These people that I have been associated

with are what makes companies like Sperry and LM great, although I miss

the “old days” when we played as hard (harder in some cases)

as we worked.

2.4 Kevin R. Giles, CIA, CPA [2002-present]

Manager of Regulatory Compliance, MS2 Tactical Systems

Directly reports to the MS2 Audit Director in Moorestown, NJ and indirectly

reports to the local CFO and Director of Business Management in Eagan

MN facility. Manages a department of five employees. Manages the residency

and is the primary point of contact for sixteen governmental audit (DCAA)

and engineering quality (DCMA) in-house oversight agents at the Eagan

Facility.

• Site Audit and Regulatory Compliance Lead for a $750 million dollar Tactical

Systems Line of Business (LOB) with locations in Eagan MN, Clearwater

FL, San Diego CA, and Virginia Beach VA.

• Responsible for overhead rate negotiations and final incurred cost reporting

with the US Government.

• Ensures LOB compliance with FAR, DFAR, CAS and GAAP regulations.

• Directs financial, operational, information technology and regulatory compliance

audits.

• Manages external audits reviews by external CPA’s (Ernst and Young)

and Department of Defense Agencies such as DCAA, DCMA and DCIS.

• Implemented and managed the Tactical Systems LOB Sarbanes-Oxley compliance

program.

• Led the implementation of SAP security controls for a $4 billion LM Business

Segment.

• Member of Independent Research and Development (IR&D), New Business,

and Capital Boards for Tactical Systems LOB.

• LM21 Excellence Six Sigma Green Belt Certification (2005).

• Member of the Tactical Systems Diversity Council.

ALLINA HEALTH SYSTEM, Minneapolis, Minnesota 1997-2002

An integrated healthcare system with $3 billion in revenues and 22,000

employees.

Director, Audit Services 1999-2002 - Responsible for the direction of

internal financial and operational audits for both the Medica Division

(Insurance Business) and the Allina Hospitals and Clinics Division (Health

Care Delivery Organization). Reported to Vice President of Audit, Treasury

and Tax.

• Established and led Medica Health Plan’s regulatory compliance audit

function.

• Developed annual audit work plans through formal organization-wide risk

assessments.

• Worked with management to implement effective internal business controls.

• Coordinated the annual external financial audit by the firms of D&T

and E&Y.

• Coordinated and answered to external reviews by regulatory agencies and

authorities such as US Office of Inspector General, MN Attorney Generals

Office, MN Department of Commerce and MN Department of Health.

• Charter member of the Allina Compliance Steering Committee that established

an effective system wide compliance program.

Senior Internal Auditor, Audit Services 1997-1998

• Acted as in-charge auditor for financial, operational and regulatory compliance

audits.

• Conducted audits on Allina Health System’s corporate and shared service

functions such as Treasury, Tax, Payroll, Human Resources/Employee Benefits

and Accounts Payable.

• Utilized Audit Command Language (ACL) software to do 100% sample data analysis

reviews.

• Performed audits for Medica Health Plan on the following functions: Billing

and Enrollment, Provider Network and Contracting, Claims Payment Systems,

Medical Management, Vendor Management and Administrative Expenditures.

VIRCHOW, KRAUSE AND COMPANY, LLP, Minneapolis, Minnesota 1994-1997

- An upper-midwest regional based consulting and CPA firm with over

900 associates.

Senior Staff Accountant

• Led audit engagements for entities with assets up to $400,000,000 and was

responsible for their related tax returns.

• Supervised and reviewed the work of up to five junior staff accountants.

• Industries involved with: Employee benefit plans including 401k/403b and

multi-employer plans, healthcare, higher education, HUD audits and nonprofit

organizations.

PETERSON AND COMPANY, CPA’S, Mankato, Minnesota 1992-1994 - A

local accounting firm now part Larson Allen, LLP

Staff Accountant

• Assisted in audits of nonprofit organizations, utilities, local governments,

school districts, insurance trusts and wholesale distribution corporations.

• Prepared tax returns and conducted tax research for individuals, partnerships

and corporations.

IMMANUEL ST. JOSEPH’S HOSPITAL, Mankato, Minnesota 1991-1992 -

This 278 bed hospital is part of the Mayo System and serves south-central

Minnesota.

Accounting Intern

• Performed a 12-month internship program in the Fiscal Service Department

under the supervision of the Controller.

• Responsible for compiling the operational and capital budgets and assisted

in the preparation of the Medicare Cost Report.

• Forecasted hospital statistics and maintained hospital databases.

MINNESOTA ARMY NATIONAL GUARD, St. Cloud, Minnesota 1983-1994

Squad Leader; Rank: Staff Sergeant E-6

• Responsible for a 10-soldier transportation squad.

• Interim Platoon Sergeant (1994) responsible for 40-soldiers and over $2

million in equipment.

• Graduate of three US Army Leadership Courses.

VOLUNTEER ACTIVITY

TEACHER FEDERAL CREDIT UNION (TFCU), Plymouth, Minnesota 2007-Present

TFCU is a 50,000 plus member financial institution with assets in excess

of $500 million serving the Twin Cities and Rural Minnesota.

Secretary of the Supervisory (Audit) Committee

• Serving a volunteer position with a two-year team appointed by the TFCU

Board

• Oversees the credit unions internal audit function and external audits and

examinations

EDUCATION

Minnesota State University, Mankato, Minnesota 1992 - Bachelor of Science,

Major: Accounting, Graduated Magna Cum Laude

PROFESSIONAL MEMBERSHIP

American Institute of Certified Public Accountants (AICPA) since 1994

Institute for Internal Auditors and Twin Cities Chapter of the IIA since

1997

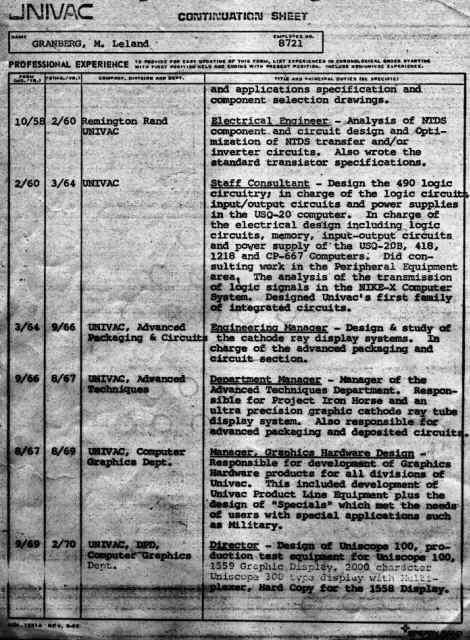

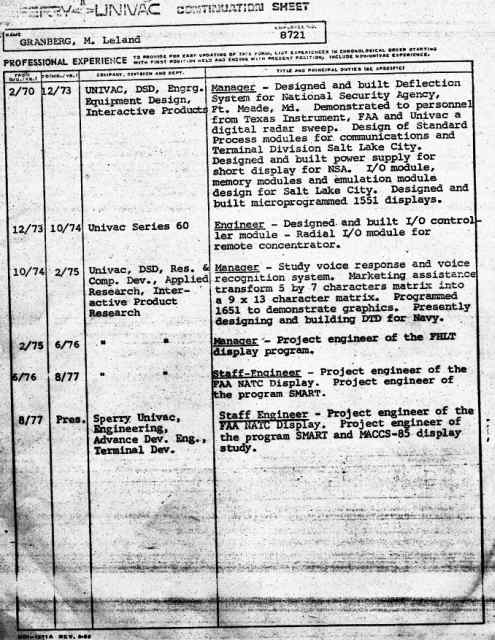

2.5 Lee Granberg, 1956 -?

When asked to write a career summary, Lee submitted two staff data

sheets.

As

an electrical engineer and manager, Lee has received more patents than

any other Legacy person - The Engineering, Patents page lists some of

them.

2.6 Paul Gregory ?-1969, 1972-

Now you're really challenging my memory. I left Univac in 1969 to work for a small company called Macro corp. Worked on computers such as the XDS (Xerox Data Systems) Sigma, and others now long forgotten. Then I returned to Univac at Warminster in 1972. Initially there, I worked on the LAMPS ASW acoustic processor, built in ST. Paul, Plant 1 or 2. It was competing with IBM's Proteus signal processor which IBM won. Other Projects at that time were ANEW, which Gerry Butenhoff worked on and a little later the P-3C System Test Program, which moved to Warminster from Dam Neck, VA. When I went to Warminster in 1972, Tom Rougier was the site manager for a short time, then he went to St. Paul. Tom Allen took over and he eventually went to St. Paul, then Jim Sarver came down from New Jersey and took over. Prior to Tom Rougier it was Ron Sagle [who left and formed GRD] and prior to Sagle it was Lynn Keefer. S-3A was moved to Warminster [now Southampton] around 1977, John Gan was project manager. After John left in 1980 I became S-3A project manager.

Gerry Butenhoff helped refresh my memory so I'm going to forward your history to him. [submitted via Gerry Pickering]

2.7 Thomas Grendzinski, 1968-

In 1968, as I decided a career in the United States Army Artillery

was not my forte, I begin looking in technical publications at advertisements

by technology companies offering computer programming careers. I sent

letters of application to many, but the UNIVAC name was a favorite of

mine, and I was fortunate to receive an interview that followed with

a job offer which I accepted. In those day a few libations during the

interview lunch were common and made the afternoon interview less tense

than the morning interview.

My degree in mathematics in 1965 included a semester of

programming a computer which was shared with two other universities

making our hands on use limited to weeks. Punched data cards, FORTRAN

language, and trial and error debug were the learning experience. After

university, I worked for a short time while my wife was to complete

her final semester. But the conflict in Southeast Asia was current and

I signed up and completed basic training at Fort Leonard Wood, Missouri

and officer candidate school at Fort Sill, Oklahoma. I was assigned

to the artillery school at Fort Sill and was asked to program an Army

computer for surveying solutions, for geodesic solutions, and also for

sound ranging (acoustic) solutions. Fan-folded paper tape input, octal

numbered machine code, and limited documentation is what awaited me.

At first I failed, but never gave up, and I completed my tasks with

excellent results.

I started my employment with UNIVAC - the name of the company

has changed many times, I am finishing my career in an office quite

near the one in which I started my career at a company now known as

Lockheed Martin. We were a group of people not knowing we were establishing

a software engineering discipline and what was to follow in industry

and universities. We were mathematics degreed, science degreed, music

degreed, and came from teaching and preaching and all other contributing

careers. We learned on the job and we taught the job.

I worked on providing software for the United States Navy

(USN). Our team developed command and control software for surface ships

and then for subsurface vessels. We interfaced the sensors and weapons

and support systems and fighters with Univac computers and software.

The engineers from land locked Eagan traveled to the East Coast and

traveled to the West Coast to USN laboratories to prove our products.

We programmed the CP-642B and CP-667 (a dual mode 30 or 36 bit machine

(only a few were ever produced)) using the CS-1 programming language.

We used magnetic tape for input and output and debugged using simulation

software. UNIVAC was on the forefront of transforming the USN from the

World War II Navy to the Navy of recent years. The transformation continues

this century with some of the same UNIVAC people of the 1960’s.

Next, I worked on an international program, the Royal Australian

Navy DDG Tactical Data System (AN/UYK-7 computers and the CMS-2 programming

language). Once the initial work was completed at Eagan, I supported

the products on site in Canberra, Australia for four years in the late

1970’s and early 1980’s. This was one of the first successful

international programs for the Eagan based enterprise. It also provided

a young family of four the chance to travel to and live in a different

country, although, in many ways, not unlike our own.

Upon my return from Australia, I worked on the design demonstration

of the AN/UYK-43 and AN/UYK-44 computers. Sperry Corporation, which

was us, won the production contract and produced many of these machines.

I worked on the Canadian Patrol Frigate (CPF) program definition

phase which resulted in a contract award. Many people traveled to Montreal

to a new company subsidiary of Unisys named Paramax which was formed

to provide international content and technology infusion. This also

was a very successful program. It was a large program employing hundreds

of people with the many coordination problems between the engineering

disciples and the performing of work at two different international

locations separated by distance that only air travel could overcome.

The CPF Program contained significant international content which provided

the system and software engineering challenge of interfacing the various

subsystems with a distributed computing system using multiple computers

(AN/UYK-502) and a data bus (SHINPADS). During this program I performed

quality assurance tasks and supervised and coordinated a group of quality

engineers.

The USN turned to us in 1989 to provide an upgrade to the

P-3C airplane of new and modern software and computing device. This

was a legacy program that Univac had performed on initially when the

airplane and its mission were first established. The upgrade program

was called CP-2044. I supervised a group of quality engineers on this

program. It was a time when new high order programming languages were

being introduced and a time when software engineering was being transitioned

to a process oriented discipline. The Ada programming language, structured

object-oriented design, work stations interfaced into the development

environment, phased development, and documented engineering processes

were introduced. Many improvements to the P-3C mission system were made

and many improvements to the software engineering discipline were made.

Because of the two, CP-2044 was program of the year.

This was now the generation of Commercial-Off-the-Shelf

(COTS) era for software and hardware that is glued and packaged together

for our customer’s unique applications. No more designing product

from birth which required a long development phase, but also resulted

in long life spans for our products. Instead, technology infusion is

planned and exercised from the very beginning of contract award.

Following CP-2044, another Australian project came to Eagan.

The Australian Air Force requested us to provide a mission system upgrade

for their P-3Cs. Our company was contracted to E-Systems, the prime

contractor, located in Greenville, Texas. There were difficult moments

between the two contractors with regard to requirements and schedule

and cost. Good engineering and program management leadership prevailed

and excellent software and hardware were delivered to the Australian

Air Force. I supervised a hardware and software test group which was

mainly responsible for the success of this program. In reality, I was

fortunate to be with a group of project people that did not give up

and I was swept along with their success.

I then entered the fall (talking autumn (or ending), not

failure) portion of my career doing various system engineering work

on programs e.g. BMUP (a P-3C upgrade), Deepwater (United States Coast

Guard); proposals e.g. P-3Cs for Taiwan, Portugal, Korea, Multi-Mission

Maritime Aircraft (MMA) for the USN.

The corporate name transitioned from UNIVAC to Lockheed

Martin. Fan-folded punched paper tape holding code used with refrigerator

sized computers to calling card sized computing devices with unlimited

memory availability. It was a good career.

2.8 Bruce Grewenow, 1965-2001

The early 1960’s was a great time

to be an engineer. I graduated from the University of Minnesota with

a Bachelor of Electrical Engineering in 1963 and took a job with Lockheed

Missiles and Space Co. in Sunnyvale, CA. Had I remained in Defense business

I would have retired with Lockheed. Lockheed had a great program for

new hires; work 3 months in a department, move to another, do this for

a year and settle down. I settled in Training and taught Theory of Operation,

Maintenance, and Programming at the remote satellite tracking stations.

Three months on the road at a time was too much for a new family and

I joined Univac-Advanced Tactical Systems as a System Design Engineer

in late 1965.

I am one of the luckiest guys in the company with bosses,

mentors, and teammates. It started with Don Woodard, Chuck Burk, Hank

Zelenka, and Dave Kolling. The test and system integration software

we developed had to be ground-breaking as no one had ever done this

before; and it ensured the reliability and operability of the Navy Combat

Systems. Conducting the AN/SPS-48 Radar/NTDS System Test on a new carrier,

the Kennedy, was awesome. So was playing chess at lunch time with Curt

Brasket, master chess player and Minnesota State champion. In the 1990’s

talking to young employees about standing in front of the computer and

debugging the s/w by observing the bit pattern in 18 or 24 lights; or

removing an 8K memory drawer with two guys as it weighted over 150 pounds,

elicited looks of disbelief and “ya sure” responses. On

one debugging trip to work on a Minesweeper project at the Brooklyn

Navy shipyard my wife was with me. She got on a TV quiz show, Eye Guess

(Bill Cullen host) and won a trip to Paris for two and $5K in merchandise.

1969: Became the supervisor of System Test, the NTDS library, and the Military Equipment Test Center (METC). It was my first management experience and I also represented Univac at the NTDS Change Control Board meeting every month in D.C. This was the onset of hundreds of trips to DC over the next 30 years.

1972: Late in the year a career changing

experience brought me to the international business area. Jerry Meyer

offered me the Program Management job on a new project; the Royal Australian

Navy (RAN) Naval Combat Data System (NCDS). This was one of several

USN Foreign Military sales programs awarded to UNIVAC and began my 30

years in international business. Morley Moe was the Project Engineer.

We had some very interesting people to work with in Australia and some

of you will recall the USN PM Faith Rawdon-Smith. The RAN NCDS project

involved the design and construction of a Combat Data Systems Centre

(CDSC) in Canberra, extensive modifications to the s/w, and installation

on 3 RAN DDG’s. When the first DDG arrived in Long Beach, CA for

retrofit; Univac, Hughes, and Collins threw a big party for the RAN

officers on a paddle wheel boat in the harbor. Dick Seaberg approved

travel for many of us to go with wives, he and his wife went too; and

we all stayed onboard the Queen Mary. The RAN Captain thanked me after

the party and said how great it was forUNIVAC to put-on the party. I

felt obligated to tell him there were two other companies involved.

This project was very successful and resulted in a strong

letter of commendation from the Australian Dept of Defense thanking

Denny Drake, Jerry McGee, Morley Moe, and myself for a super job. In

later years UNIVAC established a joint venture company (C3I) with EMI

Australia (EMI worked closely with us in the CDSC) and we transferred

mil-spec circuit board technology to Morris Productions in Sydney, thirty

years later I still communicate with 3 of the Aussie partners.

1974: New assignment now included project

management responsibility for all International Navy applications, primarily

German, Japanese and Australian programs and follow-on marketing in

France and Italy. Don Lovely’s write-up in the Systems-International

Section of the Legacy provides an excellent description of our on-going

Japanese Navy business. New projects about this time were Australian

Submarine FCS (AN/UYK-20 h/w only), Collins Link 11, and TENNE s/w in

Germany. I got a lot of help in Germany from a guy who really knew his

way around, Dennis Christ. I am glad we worked well together, we would

meet again. There were some business issues in Japan that needed resolution

and I worked with Tommy Tamagawa (former Japanese Naval Attaché to the

USA ... then with UNIVAC in DC) and Taki Saito in our Tokyo

office to fix them. More appropriate would be, I accompanied Tamagawa

while we determined what was needed and he determined how to fix it.

Tamagawa’s leadership/mentoring would serve me the rest of my

career.

He and I made a trip to Indonesia to see if there was work

there for us. He had many contacts high up in the Indonesian Navy and

after a week in Jakarta, he said … “let’s go home,

we can’t do business here.” Wise man Tamagawa. One more

story... at a dinner in Yokosuka with Tommy and all high ranking officers

(I was the only non-Japanese), I asked my server what the impressive

calligraphy behind me on the wall said. She looked nervous and asked

Tommy something in Japanese and he said “you can tell him.”

It was a very complementary description of the beautiful tatami room

we were in, the food and servers … signed by Adm. Yamamoto, circa

1942. Some things one never forgets.

1966-1980 Summary: Throughout this time period our International business underwent many changes and if I may borrow from Chuck Hammond for a moment, it will provide a better picture of the exciting opportunities and the sequence of events. In 1966 Univac DSD was awarded its first major international program, the German B-2 program. It was an FMS Case and was the start of an excellent relationship with the USN FMS organization. Several other career write-ups do an outstanding job of covering the German projects in detail. The USN was actively marketing NTDS hardware and software to NATO and sales were made to the Italian and French Navies around the same time. German opportunities resulted in our Paris office moving to Bonn in 1968; followed by the German Fast Patrol Boat contract in 1969. Then the USN turned its FMS attention to the Pacific and Mid-East. In 1972 we were awarded the Japanese DDG Combat Data System, followed by Australian DDGs in 1973, and in 1975 the Iranian DD-993 Destroyer Project which was an order of magnitude larger than any DSD international contract to that date. At this point the USN lost interest in actively marketing FMS business. This factor, coupled with the large business base with Iran, Germany, Japan, and Australia prompted DSD to form the International Systems Division. From 1975 through 1979 the successful awards were: Japan ATC, Canadian CP-140, German Flight Plan Processing (ZKSD), German F-122 Frigate, two communication systems projects with Israel, Japanese P-3C Ground Support System, German S-143A FPB, Korean ATC, Greek Submarine FCS, Saudi Naval Expansion Program, and h/w sales to the United Kingdom. International revenue had grown from $10-15M per year in the early 70’s to $102M in 1979. Marketing offices had opened in Tokyo, Canberra, and Athens. Consultant contracts were established in Egypt, Korea, Taiwan, Malaysia, Yugoslavia, Spain, and Israel. The Canadian operations opened a sales office in Ottawa in 1978 and with the CPF win a separate subsidiary was set up. The CPF contract was then estimated to be valued at over $1B for Sperry and $200M to CSD. ISD was disbanded back to the functional divisions in 1979. One had to be flexible in these times to work in international business.

1977: In the summer of 1977 the Australian Navy awarded us a contract to conduct a 6 month trade-off study in Canberra, to determine the best combat system for a class of small ships … the Small Ship Combat Data System (SSCDS). This was a marketing dream. We were fully funded by the RAN and I took a team of talented people with families to Canberra for 6 months. We brought down specific experience as required. Our original RAN NCDS team of Denny Drake and Morley Moe led the engineering studies; supported by visits from Chuck Burk, Ernie Lantto, and others I know I should recall but can’t. With a team like that and Lynn Keefer managing the marketing aspects, success was assured. Surprisingly, after studying systems from around the world we recommended a version of the USN NTDS … hard to believe. It was however, so obviously the best combat system that no one could argue with the result. We made a final day long presentation to over 100 Aussies including a few Admirals. Jim Stahley was my boss and he came down for the presentation too. The RAN were very impressed and wanted to get us under contract ASAP. Unfortunately, an Australian election took place shortly after our presentation … the labor party won over the conservatives and they cut all new funding for the RAN. So close … welcome to the International Market.

1979: Jim Stahley had a new assignment for me; PM for the AN/UYK-502 computer project. The UYK-502 would be the first DSD product to be built entirely out side the USA, using only company sponsored funds and sold world-wide. Development and preproduction would be in Minnesota and transferred to Winnipeg for production. We developed a 502 business plan with the Canadian Government, focusing the UYK-502 on CPF and SHINPADS. However, during the monthly project reviews with Dick Seaberg, he would almost grab Carl Boecher by the lapels and shout “when are you going to sell this product outside of Canada.” Carl had a tough job and I don’t know for sure if we ever sold a 502 outside of Canada. Carl became the CEO of another company so has had a successful career. Working with Doug Hair and Glen (Easy) Johnson on the project was a wonderful learning experience for me as all of my experience had been in systems. Another lucky break for me.

1983: Because of my involvement on the UYK-502 with manufacturing and Canadian Operations I moved on to a totally different arena and left international for two years. Myron Lecy was forming a group to build the Material Management Center. He asked me to join him as a Group Manager Business Management with a job description that was a bit vague (a positive as it let me get involved in many issues). It was an exciting move; the job was to develop and direct MMC plans, policies, and procedures; manage the material acquisition process for major DSD products, and develop strategic business plans linking critical suppliers to DSD. Also, do supplier evaluations, just-in-time deliveries (new concept at that time); and I served on the Corporate Material Management Council and International Offset Committee. The MMC experience was two years of energizing development and learning, working with Myron, Bob Shutt, Marilyn Snyder, and Glen Dykes … you all taught me a lot about a new line of business.

1985: International Program Management called again in the voice of Tom Morris. There were some issues with a follow-on FMS contract with the Australian Navy project and the RAN asked if I would come back and assist. Tom offered me the position of Director of International PM. I spent some time in Australia and we were able to successfully resolve the problem. Adm. Meinig, US Naval Sea Systems Command wrote a glowing letter of commendation to Al Zettlemoyer extending his personal thanks and appreciation on our teams’ performance. Exact quote: “The performance of your personnel was fully equal to the high standards we have come to expect from Unisys.” Chuck Hammond came on the scene from the USAF with extensive European experience and connections and I now reported to him as PM of International Operations providing management direction for all International projects (except Canada). I have lost track of what happened to bring about these changes. Chuck was with-out-a-doubt Mr. International, a great mentor, boss, and friend. In this time period a group of project managers came to International, we would work together for many years, a formidable team of international experience and talent: Doug Schmitt, Tom Kratz, Bob Pagac, Woody Spitzmueller, Larry Pierson, John Booher, and Dick Johnson; all of us made successful by Mr. International Contracts: Don Blattie.

1990: Now the job got even more interesting and challenging. I worked for Dennis Christ as Director of International Systems, with the added responsibility of an International Engineering group under Max Tiede and the German Military Systems Division under Manfred Wiese. Again I had the good fortune to work for a great boss with extensive international experience and a super team of people. Major programs at this time were the German F-123 Frigate ($28M), Hellenic Navy Submarine FCS ($39M), Egypt Submarine ($25M), and Japan P-3C ($100M). However, the CSD management structure was not politically suited for a separate International group and we were eventually moved back into the various functional organizations. One might note that this seemed to occur every decade, especially when international was successful.

1992: I was fortunate enough to end-up working in Marketing for Jim Chupurdia, responsible for all International business (except Canada). This too was an exciting organization with key programs focused by region: Mideast and Africa/ABCCC; Europe/CP-2044; Thailand/RTADS III; Asia and Australia/CP-2044; and ATC/Hong Kong ATC. Later in 1992 the group became Information Processing Systems and Custom Products Marketing with additional personnel covering the B-2 ACU/ACUE; Contract Manufacturing; Intra-company business; and Air Force C3I. However … this too shall come to pass … one must be flexible in the International arena.

1993: Unisys Commercial operations in Brazil

wanted to team with Mitsui Brazil to purse a $1B project called SIVAM:

Sistema de Vigilancia da Amazonia … or System for Surveillance

of the Amazon. Unisys Brazil did not have the experience to put together

a team involving radar, air planes, massive command and control centers,

and $300M subcontracts. They asked corporate HQ for help from Defense

to lead this effort and provide the management and engineering skills.

Dennis Christ and Jim Chupurdia asked me to be the Acquisition Director

and good fortune smiled again as the team came together with Rob Sedlacek

for Business Development; Tony Beck and Quint Heckert as the engineering

leads; Merle Cole from subcontracts, Guy Eastman proposal management –

it doesn’t get any better than that. Many people worked on this

proposal over almost two years and I want to thank them all again. I

believe to this day that we had the best technical solution, the strongest

subcontractor team and “eventually” equal financing. I am

in awe today of the team that developed our proposal; you would have

to see it to believe it. SIVAM bidders not only had to provide solutions

for a myriad of very complex issues but finance the project as well.

Our financing was coming from a Japanese Environmental Fund via Mitsui

at extremely favorable rates …a key reason Unisys Brazil opted

to purse the project. It would take a dozen more pages to adequately

describe the SIVAM technical solution; a summary at a very high level

follows. Remember most of the Amazon Basin is utterly remote, huge …well

you know the rest. System must provide: Environmental Surveillance,

Support for Sustainable Development, Social Services for Native Population,

Health Programs, Sanitary Control, Civil Defense, Control Illicit Activities

(Drugs...Logging..Gold Mining Pollution...etc.), Weather Monitoring

and Forecasting, Border Surveillance, Aerial and Territorial Surveillance

(via satellites and aircraft), Air Traffic Control (when one flew over

the Amazon at that time you essentially disappeared), and Monitor River

Navigation. There would be three regional surveillance centers in Amazonian

cities to gather and process the information; with all activities coordinated

by a Management Control Center in Brasilia.

Unisys would be the prime contractor/integrator through

a subsidiary we established, Unisys Brazilian Systems of which I was

the legal representative. Key subcontractors: Westinghouse: Radars and

AEW; Hughes: ATC and Real Time Surveillance; NEC do Brazil: Communications;

Environmental Research Institute of Michigan: Satellite Technology for

Meteorology/Atmospheric Monitoring; Embraer: Lab Aircraft/Airborne Surveillance;

Tecnasa: Weather Radar/Communications. Eventually Lockheed would provide

C130 Aircraft and AEW.

On one of our many trips to Brazil we took our team into

the Amazon Basin to see for ourselves the environment in which we would

work. Rob, Tony, Quint, Merle, and I flew into Bogotá, Columbia and

missed the connecting flight to Manaus, Brazil. Two nights in Bogotá

with gun fire outside our hotel was exciting. Finally we got to Manaus

in the heart of the Basin where the Solimoes and Rio Negro Rivers join

to form the Amazon River. Along with reps from Westinghouse and Unisys

Brazil we flew in a chartered plane up the Rio Negro to a small town

near the Columbian border. It looked like a western town in the US back

in the 1800’s, with gold assay offices included. We learned a

lot from that trip and had a much greater appreciation for the task

ahead of us.

We did not win the SIVAM project for a variety of reasons

that were summarized in a lessons learned summary to the CEO, Jim Unruh.

I believe financing issues were the key problem. The Japanese loan became

doubtful late in the bid process. I worked with the US EXIM Bank and

was able to set-up a $700M loan late in the bid process; albeit the

rates were higher and the low cost loan from Japan was a primary reason

for pursuit. Raytheon played the political game at a level with both

Governments that we did not approach and their top management, including

the CEO, was actively involved in every detail. It was said in the press

that they delivered a copy of the proposal to Bill Clinton for support.

The down select was surprisingly moved up to May 24, 1994. We were in

Sao Paulo with Dennis Christ and key execs from our subcontractors for

some politicking of our own when we got the word. Brazilian elections

were coming up in October and the incumbent government polls were weak;

they wanted to award a contract before the elections. DASA and Unisys

were eliminated; Raytheon and Thompson CSF were finalists.

The controversy that ensued over the next two years bordered

on unbelievable to say the least. A full page article in Business Week

(Dec. 95), and other stories in the Wall Street Journal, NY Times, and

many more pubs described the scandal surrounding the SIVAM bid process:

alleged bribery by the down selected companies, fraud involving the

Brazilian system integrator, ESCA; and much, much more. I had a file

full of press clippings. No contracts were awarded until years later

when Raytheon got a piece of the action. I wonder today, if we had made

the down select and won a $1B contract at the very time Unisys was selling

Defense, what would have happened???

I spent the next 6 months working on a Business Plan I called GEMS: Global Environmental Monitoring System. Vietnam was quite interested, Quint or Tony made one trip; but no company funding was available to pursue the possibilities. The Defense business was in the process of being sold to Loral and a new costly pursuit like GEMS was not viable. I moved to Unisys Commercial as a Principal in the Services Business thanks to all the good contacts from SIVAM. I still have a letter from the Brazilian Ambassador, whom I had met in Washington D.C.; addressed to me: President Unisys Corporation. I didn’t use this letter in moving from Defense to Commercial on the very day Loral bought Defense Operations.

The next 5-6 years were spent working in almost every Asian country, Australia, and New Zealand; and I made one more memorable trip to Brazil. Retired in 2001. I would like to thank all the brilliant engineers and teammates who made my job easy; the mentors/bosses who taught me how to do business and made each day a great experience…what a fantastic company and group of people.

2.9 Burton Gunderson, 1961 to 2002

After graduating from Concordia College-Moorhead Minnesota with majors in math and physics in May 1961, I joined a company known as Remington Rand Univac (RRU) on June 12, 1961. I had been interviewed and subsequently hired earlier in the spring. The trip to St. Paul from Fargo for the interview was the first plane trip I had ever taken and little did I know how many trips and time on airplanes were in store for me with my new job. I was hired in as an associate programmer at $104.00/week. A couple of fellow Concordia graduates were hired by Control Data as programmers and interestingly enough, they were offered the identical salary. Over nearly 41 years with the company from RRU to retirement from Lockheed Martin, I was fortunate to work on so many interesting projects and with so many great people, it is hard to summarize, but I will hit the highlights.

My first assignment was in the Nike Zeus Dept. which was under the

direction of Earl Joseph. My first immediate supervisor was Bob Remund.

But, before I could actually start the project, I attended two months

of training in programming the Nike Zeus Target Intercept computer and

the IBM 7090. This training was conducted by Sam Poppleton at the training

facility on the corner of Ford Parkway and Mississippi Blvd [Editor's

note: the original plant 6]. The next generation Nike computer called

the General Purpose Digital Computer (GPDC) was under development and

we were to write an assembler and GPDC simulator for Bell Telephone

Labs (BTL) in Whippany, New Jersey, to run on the IBM 7090. I worked

on the assembler and traveled to BTL for debugging, testing and maintenance

of the assembler. T he GPDC had a unique read-only memory system which

consisted of bits of oxide on aluminum cards which were about the size

of a punch card. The GPDC became part of the Multi Array Radar/White

Sands (MAR/WS) System, and I participated in writing of the Operational

Real-Time Program and the Data Reduction Program. I also was responsible

for converting the assembler to GPDC code so we could assemble our programs

on the GPDC on-site instead of at BTL. The MAR/WS system was being developed

by the Sylvania Corp. in Boston and installed at White Sands Missile

Range, New Mexico. So, this project required extensive travel to Boston,

White Sands and New Jersey for checkout. As a sidelight to this, I was

on a trip to Sylvania in Boston with some other folks on the fateful

November 1963 day when President Kennedy was assassinated. The city

virtually shut down. It was even hard to find a restaurant open. But

Sylvania stayed open, so we had to stay and work instead of coming home.

Over the next couple of years I worked on smaller projects

developing I/O handlers for the Fastrand data storage system, displays

and printers, data reduction programs and several other operational

type programs. These projects included the Army War Room and a Navy

carrier inventory program called Moon Beam. The software was written

for the 1218 computer. The Army War Room required a lot of travel to

the Pentagon for software checkout. During this time, I also designed

and wired some 1004 plug-boards for use in the Defense Systems Computer

Center and the Navy Electronics Labs in San Diego.

For the next several years, I got into writing test software

which led to being involved in testing in one form or another for the

rest of my career. I developed test software including Design Verification

Routines (DVRs), POFAs, maintenance routines and Factory Acceptance

Tests for numerous devices including multiplexers, printers, Fastrand

II and III, displays and remote terminals. Computers that these programs

were written for included the 642B, 1230, 418 and 1108.

In 1967 I was in the first contingent of employees to move to

the new plant in Eagan at the intersection of two gravel roads in the

country. It was the only building around except for farm buildings.

The construction wasn’t complete yet when we moved in so there

were open doors, etc. I caught mice in my desk drawers for several nights

running. I remember Dick (Ole) Olson catching a bat in a cardboard box.

Through various organizational changes, I found myself in the Federal System Division under Ray Kot from 1970 to 1974 and was supervisor of a group of programmers and analysts involved primarily with development of test software and support of commercial projects including benchmark testing and post-award assistance to customers. My managers during this time frame were Don Moe and Bob Barfknecht.

In 1974 I transferred back into the Defense

Systems Division (DSD) in the Systems Evaluation Dept. under Wilt Anderson.

From 1974 to 1984, I was primarily involved in software testing as a

group leader and/or test director on several projects including Improved

Tactical Air Operations Center (ITAOC) at Camp Pendleton, California,

Tactical Flag Command Center (TFCC), Canadian Message Handling System

(CMHS), Malaysian Automatic Message Switching System (MASS) and various

other smaller efforts. During this time, I also was responsible for

publishing the DSD Software Quality Assurance Manual.

Next I was assigned to the Marine Air Traffic and Control

System (MATCALS) as lead for the software testing at Mare Island, California,

first article testing of the shelters at Plant 2 and Systems Integration

Tests at Patuxent River Naval Air Station, Maryland.

Next, in 1986 and 1987, I took a break from the testing

world and took an assignment on the Canadian Patrol Frigate (CPF) project

as the Operator Interface Coordinator responsible for standardization

of the operator interface at the various operator consoles and coordination

with operator manual developers and programmers of all aspects of the

operator interface. I went back to the test world on CPF as test lead

for the POFAs and several operational modules.

In 1988, we won the ABCCC III program to design and produce new capsules to go into the EC-130E aircraft. I was given the lead for the First Article Test & Evaluation (FAT&E) under Dick (Ole) Olson, the Project Engineer and Harry Fager, the Test Director. FAT&E consisted of all the testing required for sell-off of the first capsule system including 1) the Hardware Integration Test (HIT), 2) hardware environmental qualification including Environmental Stress Screening (ESS), vibration, temperature, de-rating, explosive atmosphere, EMI/EMC and System Safety, 3) subsystem tests for the Airborne Maintenance Subsystem, Tactical Battle-staff Management Subsystem and the Communications Subsystem and 4) the System Integration Test (SIT). HIT was a challenge from the beginning because we had to start testing before all hardware had been installed in the capsule. First we had to convince a skeptical customer that we were ready to begin testing, then, when we had some start-up problems, the customer became even more skeptical. I convinced them that if we could get past the problem we were having, the test could continue. We did continue and got through the test successfully. SIT, which involved the first installation of the ABCCC III capsule into the cargo bay of the EC-130E aircraft and integration with the aircraft systems, was a very interesting and tense time. These tests were conducted at the Air Force Reserve base in Minneapolis on a very cold day. This test had very high visibility and many management people, both Air Force and company, were on hand for the event. The first thing of course was to push the capsule into the aircraft and when it went in with no more than two inches to spare all the way around, there was a great sense of relief for all involved. Then our job was to tie down the capsule, and hook up to all the electrical, mechanical and communications interfaces and conduct the functional performance verification. Following all this, with the things heating up over the Iraq-Kuwait situation, the ABCCC III team had the pressure of completing the first two capsules so they could go through Operational Test & Evaluation and be deployed to Desert Storm. Everyone worked hard and long hours to make that happen, and the success story is history. During this time, I had very dedicated and capable help from Pat Bailey, Jan Nitti and Steve Cushing. After this, I had the responsibility of testing and selling off six more production capsules. Next we did a major enhancement to ABCCC III with the incorporation of the JTIDS data link. For testing of this we were able to get the Air Force to provide an AWACS plane for us to communicate with from the air to our installation at Corporate Square. We also had a number of test flights to verify that our JTIDS subsystem did not interfere with any of the other aircraft systems. During this time, I also had responsibility for test plans and procedures for the Advanced Planning System.

In 1994, when we (Unisys) won the Anti-Surface

Warfare Improvement Program (AIP), I joined the AIP group as the System

Test Planner responsible for development of the test requirements and

development of the plans and procedures for ground and flight tests.

An interesting thing about this program was that Lockheed Martin was

our subcontractor for the modifications to the P-3C aircraft to be done

at the LM facility in Greenville, SC. When we were bought out by LM

after a short time as Loral, we had essentially been bought by our subcontractor.

That made for some interesting relationships. Even though Eagan was

still prime on the program, I had dealings with a couple of people who

thought they were now the boss. We went on to getting the first aircraft

out of the hanger and successfully ground tested at Greenville, then

went to the Patuxent River Naval Air Station (Pax River) for flight

tests. A few of us on the program had to go through physical exams and

Aircraft Survival Training at Pax River before we could go on any test

flights. There was some question with me as far as my eyesight was concerned,

whether it was good enough to go or not. We asked the responsible Navy

person about it and he said “Mr. Gunderson isn’t going to

fly the plane, is he?” We said “No”, and he said “Well,

then, he can go.” I participated in several test flights, the

longest one being about twelve hours. Following this, I was in charge

of selling off the first 12 production aircraft at Greenville. Pat Bailey

must be given much of the credit for the success of these tests with

her great prior experience with the system software. After the first

12 production aircraft, the sell-off of the following aircraft was handed

off to the local field engineering staff in Greenville.

During this time, I was made the test lead for ASUW programs

under Jim Courtright and John Dagon and was the test IPT lead for two

more programs. We received a contract from the Royal Norwegian

Air Force for upgrades to their four P-3Cs similar to AIP. Tests on

these aircraft were also done at Greenville and Pax River. Then we received

the contract for the Block Modification Upgrade Program (BMUP) which

was a program to update some older P-3 aircraft. These aircraft were

also modified at Greenville and tested at Greenville and Pax River.

Again Pat Bailey and later Bob Buth deserve much of the credit for the

success of these test programs. During these AIP, UIP and BMUP programs,

I traveled to Greenville or Pax River approximately 70 times. I was

scheduled to go to Pax River yet one more time on 9/12/2001. Well, we

all know what happened the day before. I never made a trip for the company

again and retired on January 17, 2002.

My wife, Susan, and I are now happily retired near Lake

Wobegon, the place that time forgot, where all the men are good looking,

the women are strong, and the children are all above average.

2.10 Nancy Gunther (1966-2000)

I have read with interest the job summaries that have been posted by many of the people with whom I worked during the 35 years that I spent with Univac, Sperry Univac, Sperry Corp., Unisys, Paramax, Loral, and Lockheed Martin. If you read the job summaries posted by Dennis Abbott, Jim Bougie, Bob Bro, Quintin Heckert, and other personnel associated with NTDS and command and control systems, they represent a fairly accurate summary of the projects that I worked during my time with the company. I worked on the NTDS systems for the DLG-16, DLG-6, CVAN-68, FFG-7 (PF), and CPF surface ships; digital operating system and Over the Horizon Targeting (OTH) system for the SSN attack submarine; communications systems for the NSSN submarine; a tri-service black project, and various other projects. I worked as a programmer for 10 years and advanced to project engineer, supervisor, and manager. Adding another description of the same projects to this compendium seems a little extraneous, so I decided to tackle this job from a human-interest perspective to try and describe the environment that we worked in, and the dedication to the job that most employees displayed at that time.

I hired into Univac in 1966 after graduating from the University of Iowa, Iowa City with a degree in mathematics. My arrival was eagerly anticipated by the gentlemen working in the Advanced Tactical Systems department located in Plant 5 on Prior Ave. in St. Paul, MN. I had been highly impressed with this department because it had a sign by the door that said “access restricted to employees only” and a buzzer for the secretary to open the door. I say that my arrival was eagerly anticipated because the last few employees of the female persuasion had departed the premises earlier that year, and I was the new token female, and a pretty good looking one at that time. [For the record, I was never a token female and the guys soon learned that.] I had interviewed with one of the supervisors responsible for the NTDS system currently being developed for the DLG-16 class of ships, and I remember that during the course of the interview, I kept thinking what a good natured person he was as he smiled and smiled and smiled during the interview. Several months after I had started, and had become better acquainted with my five “cubicle mates” I was told that he was smiling because the guys had been standing up behind my back, and waving handkerchiefs and giving him the thumbs up, meaning “hire her”. The first day that I showed up for work, I was assigned to a six-man cubicle, and introduced to the five jokers already working there. I was informed by one of the more outspoken guys that that they would not be opening doors for me, lighting my cigarettes, and that I would be treated like one of the guys. I said “fine” and thus it was for the next 35 years.

During that first six months on the job, I was introduced to the wonders of military specifications, flowcharting, Mylar tape punching machines, “designation and re-designation”, the world of acronyms, Ozalid machines, and the Military Equipment Test Center (METC).

The specification I disposed of quickly. This guy kept leaving it on my desk in the mornings, I’d look at it and decided that it didn’t make any sense and it was also pretty boring, and I’d go back to the flowcharting job that I was working on. The flowcharting job was also boring, but at least I knew how to do it! Finally I asked one of my cubicle mates who the guy was and why he kept bringing that book over. I was told that the guy was my boss (no one had bothered to tell me) and the book was the [software] specification for the program that I was supposed to work on. Okey dokey.

The flowcharting task was among the more “challenging and thought provoking jobs” ever assigned to me --- just contemplate the joys of being given a listing that was two inches thick and being told to develop a flowchart for every subroutine contained within. Oh, the mind-blowing boredom of it all!

I was assigned the job of developing a small scan routine to display on the front panels of a 1218 computer after it had been booted up but before it had been initialized to run. The code was developed in assembly language, but had to be converted to machine code (I no longer remember whether it was octal, or binary for those of you that remember the good old days), and then manually punched into this machine which generated a Mylar tape that could then be loaded into the 1218 computer at METC. Any mistake made during the entry of the code, or any mistake found when debugging the program meant re-entering the entire set of code at the machine and generating another tape. Ah, the joys of working closely with the machines that were so near and dear to our hearts!

Designation and re-designation. What can I say? I didn’t have a clue what these two things were (and probably didn’t care at the time) and for the life of me, could not understand how five guys in my cubicle and four guys in the cubicle across the aisle could argue for hours and hours about it and still not resolve whatever the basic question was that they were arguing about. I finally realized that “designating” meant assigning a fire control system to a target but I’m not sure anyone ever did come to any agreement on the definition of “re-designating”. Is the world of military computing systems any richer or poorer for the lack? Probably not!

The world of acronyms at that time was a brave new frontier. As I sat at my desk listening to the talk swirl around me, it was completely incomprehensible. It was like listening to people talking in tongues. What was a BAM (Binary Angular Measurement)? What was a SWC (Ship’s Weapon Coordinator)? What was a CFU (Control Formatting Unit)? What was a KCMX (Keyset Central Multiplexer)? What were all of these people talking about? Did they think that I was going to absorb it by osmosis? I started asking questions and developing lists and in future years, whenever a new hire started, a list of acronyms was one of the first things that I provided.

Ye olde ozalid machine. Anyone remember it? The youngsters of the world do not remember a time without copying machines but in that era, secretaries typed memos in triplicate and that was the maximum number of copies ever information needed to be shared or disseminated, a distribution list was attached and the memo was circulated. There was always at least one yo-yo in the department that ferreted the memo away and didn’t get around to reading it, and held up circulation. The ozalid machine could be used to make copies of over sized drawings. It was located in Plant 2 and you had to wait at a counter while an operator made the copies. As I recall, the copies were printed on a thin, almost tissue-like paper, and the ink was blue and blurred.

The Military Equipment Test Center (METC) was located in Plant 2. In 1966, it consisted of a 1218 computer, a paper tape reader, a magnetic tape reader, and probably a 642 computer. It was good only for local debugging and for any system level debugging, we had to take trips to Mare Island Naval Shipyard at Vallejo, CA. Over the years, the equipment configuration increased significantly to the point that all of the debugging, testing, and certification of the systems was performed at METC, and Mare Island and other sites were used only for integration with other systems. I fondly remember the patch panels that were six feet high and probably six feet wide. I felt as though I had conquered the world of technology once I had learned to cable up a system consisting of two 642 B computers, one or two 1218 computers, associated paper and magnetic tapes, and teletype machines. I’m sure it was a sight to behold in the late sixties when I was wearing a mini-dress and high heels and stretching to reach the top of the switchboard and squatting to access the bottom of it. At one point in time, years later when I was supervising, I had paid a late night visit to METC to check on progress during the midnight shift, and one of the wits had printed on the blackboard “Beam me up, Scotty, there’s no intelligent life down here”.

There are more humorous stories than there is room to repeat them, but some of my fondest recollections are of banter in the office and just idiotic things that happened on the job.

I often wondered what our men in uniform (because there weren’t any or many women working on computerized system development projects at that time) would have thought about some of the dialog between the programmers as they were diligently developing what were considered high tech systems at the time. Some of the classic and often repeated remarks are as follows: “Hey Joe, is port left or right?” “How many fire control systems are there on this ship? “Is aft the front or the back? “Well, then what’s the stern?” “What’s the front of the ship called? Is pitch and roll to the side?” “What's yaw?” “What’s the difference between a radar mile and a regular mile? Why don’t they use regular miles?” “How come he’s got one stripe on his shoulder and the other guy has two?”