Information Technology (IT) Pioneers

Retirees and former employees of Unisys, Lockheed Martin, and their heritage companies

People T-Z, Chapter 18

1. Topical Article Contributors

20 writers have written 55 articles or tidbits, these complement the 190+ submitted career summaries.

- Eric Taipale, Harvey Taipale, John Thalhuber, Todd J. Thomas, Tom Turba, and Glen Turner.

- Willis Unke.

- Tom Van Keuren and Earl M. Vraa.

- Tom Webb, Cal Webster, Don Weidenbach, Paul Welshinger, Douglas C. Wendall Jr., John Westergren, Manfred Wiese, Gerry Williams, Lou Wilson, Harry Wise, and Mike Wold.

2. Career Summaries - T:

2.1 Ed Tilford Sr., 1967 – 1992;

My History Line

- Vandenberg AFB - Guidance Equations Development, Trajectory Design & Analysis

- Eagan, MN ATC - IR&D

- Knoxville, TN - Voice Advisory System Implementation & Testing

- Eagan, MN - Collision Avoidance System Software Design

- Sudbury, MA - Division Liaison to Sperry Research Center

- Atlantic City, NJ - Terminal ATC Systems Development & Testing

- Eagan, MN - Software Engineering Resource Management

- Montreal Canada - Management of On-Site Canadian Patrol Frigate Software Development

- Eagan, MN - Management of Software Engineering

I graduated from Kansas State University in 1960

with a dual major in mathematics and physics. I graduated from the University

of Missouri in 1962 with an MA in pure mathematics. My first job was

with General Dynamics in San Diego. My next job, because of a change

of prime contractor, was with Lockheed in Sunnyvale. All of my work

with both companies was in the area of trajectory design and guidance

equations development for reconnaissance “Corona” satellites.

I moved to Sperry Univac at Vandenberg AFB in 1967, again to develop

trajectory mathematics and guidance equations for Corona satellites.

Even though my college training was technical, what left a lasting

impression on me were the people I worked with. Sure, we had a lot of

tough technical problems to resolve, but there were even more relationship

problems and successes. One particular project in the late 1960’s

illustrates this quite well. The project was called HAP for High Altitude

nuclear readiness to test Project. From CIA intelligence the United

States learned that the Chinese were getting ready to resume high altitude

nuclear testing. The U.S. assembled a very small team to beat them to

first test with the hope that our demonstration would discourage them

from testing. The team was sent to Johnston Island in the Pacific and

given a very short schedule for getting up and demonstrating a first

test. At one point there was serious thought given to actually detonating

a nuclear device. Thankfully clearer heads prevailed and we decided

to use a very bright non-nuclear device. We worked at night getting

the launch vehicle, guidance system and trajectory design completed.

The trajectory had a very high apogee and low perigee. During the countdown

we picked up on radar a Russian trawler parked right under the path

of the vehicle. If we had to blow the missile, we were concerned we

would hit the trawler. We tried to communicate with the Russians but

got no response. Being young and naive I suggested that we stop communicating

in Russian and communicate in English and, if they would move to a position

we specified, we would hand over to them a complete copy of all telemetry

data from the launch. The Admiral in charge of the project said, “go

for it!” I got on the radio and made the proposal. After a few

minutes of silence, very clearly over the COM system, in English we

heard, “you are on.” They moved, we launched and I was given

the task of hand delivering the telemetry tapes. It turns out that the

captain and his first officer were University of California and Cal

Tech graduates. We had vodka and some conversation about all the very

interesting “fishing” equipment they had on board and I

departed. Until now I have never given out details of this story. While

researching for this write-up I went to a Web site: www.johnstonmemories.com

and other Web sites and discovered that the project had been declassified.

From capturing satellites to Air Traffic Control Systems to the

Canadian Patrol Frigate, I was a witness to greatness because of the

people I worked with!

![]()

2.2 Joel Tofteland, 1973-

I started employment with UNIVAC on May 16, 1973,

as a Logistics Analyst providing Provisioning Technical Documentation

on AN/UYK-7(V) computers delivered to the Navy. This time-consuming

task required a lot of manual intervention of gathering data from engineering

bill of material listings and associated hard copy drawings to build

a top down assembly listing of the modules and piece parts that made

up a particular configuration of the delivered computer. Data reports

were built from 80 column Electronic Counting Machine (EAM) cards containing

data formatted to U.S. government MIL-STD format. The EAM cards were

run through a UNIVAC card processor to print deliverable lists submitted

to customer under contract letter—a far cry from today’s

fully electronic data collection and submittal process in specified

customer electronic files.

I branched out a year later to the supply support function of

coordinating the first UNIVAC contracted depot level repair program

for the Navy Aviation Control Office (ASO) in Philadelphia, PA, in June

1974. The Navy program centered on providing dedicated repair and transportation

to re-supply designated P-3 CP-901 computer modules that UNIVAC designed

and built. The whole effort was mandated through the use of NAVAIR’s

Closed Loop Aeronautical Management Program (CLAMP) that monitored and

controlled repairable assets and rotatable spares through the entire

retrograde, repair and return to use supply effort. This program introduced

the first dedicated transportation plan in May 1975 with the contracting

of a young upstart airfreight company named Federal Express that would

guarantee 24- to 48-hour shipment of program assets from Navy user facilities

to the UNIVAC depot repair facility in St. Paul, MN. Repaired assets

were then shipped back to Navy supply centers or directly to the NAVAIR

user facility via Federal Express shipment.

What is truly historical is that the P-3 CLAMP Program was the first Government contract Federal Express had landed for dedicated handling and shipment of material. The two Air Force Viet Nam fighter pilots who started Federal Express had conceived the idea upon separation from the service in the early 1970’s but could not put it in place without the collateral afforded by their first Government contract. This primitive start of establishing a central air freight hub in Memphis, TN, with dedicated air and ground delivery systems became the giant FEDEX Company we know today. I was fortunate in personally witnessing this leading edge technology company as it grew from a national to an international company.

All of this activity was monitored and controlled

through the use of a real-time data base established by Dynamics Research

Corporation of Boston, MA for NAVAIR. All CLAMP contractors had to utilize

prescribed data reporting formats loaded to a front end processor in

Philadelphia on TWX paper tape feed transmission. Although time-consuming

it did prove that asset management could be accomplished effectively

to meet program requirements. This effort went through a series of evolutions

with the use of the first IBM desktop computers and eventually a Web-based

program for managing resources. The early program proved so successful

that NAVAIR added the S-3A program in 1976, and the Canadian Department

of Defence in Ottawa joined in 1978 with support of their CP-140 avionics

computer. I coordinated the data management, depot repair activity,

field service support, contracts and site visit efforts for all three

programs from 1974 through 1984.

Desiring a change in program activity I got involved in 1985

with the U.S. Air Force Wild Weasel aircraft program managed out of

Hill AFB in Ogden, Utah. Sperry UNIVAC at the time provided an avionics

computer that required ILS documentation and depot repair support. That

program continued for two years, and at the same time I got involved

with supporting CP-140 depot level repairs performed in the Sperry UNIVAC

facility in Salt Lake City, UT. I coordinated repairs and spares management

along with depot reporting requirements back to the Canadian Department

of Defence.

When the Salt Lake facility became self-sufficient in 1990 I transferred

to the Trident II program by again supporting repairs and documentation

through now the Loral facilities in both St. Paul, MN, and Long Island,

NY.

In 1994 I took on repair/supply support effort

for the B-2 Bomber program managed through the prime contractor Northrop

Grumman located in Oklahoma City, OK. I managed the B-2 Interim Contractor

Support (ICS) Program for depot level repairs through calendar year

2005. In that timeframe Northrop Grumman awarded Lockheed Martin a commendation

in support of Operation Iraqi Freedom for outstanding repair support

to deployed aircraft in March 2003 and Supplier of the Year award in

2004.

In 2005 I joined the JSF program by supporting repair and retrofit

requirements located in Eagan, MN, and various team member sites. In

the same timeframe I also picked Q-70 project lead responsibility for

ILS product deliveries. That is the position I am in now.

Over the past 34.5 years this has been an interesting journey

in Logistics Support by supporting the evolution of the various products

our company has delivered to various government customers. Processes

and requirements changed all along the way but lasting friendships have

not. ![]()

2.3 Harvey Taipale - [1966-2007]

Harvey started work at Univac (on the defense side) in 1966, as a fresh college grad, lived through all the company name changes and sales and retired from Lockheed Martin in 2007. His early career was engineering and project management. His later career was in business development, primarily Navy but also internationally. He worked on Navy, FAA, and Air Force programs, was involved with many of the company's various facilities and customers in Japan, Germany, Korea, and Australia. He is presently the 2022 VIP Club President.

2.4 Tenner Thompson (1980-2012)

In 1976 I finished high school in Williston, ND, then I was off to Concordia College to get a degree in computer science with math as a backup plan.

The problem was that Concordia didn’t have a computer science major. By taking classes at North Dakota State University (NDSU) and

Minnesota State University Moorhead, I received enough credits to be the first person to graduate from Concordia College with a computer science BA,

and threw in a math major and chemistry minor.

In 1980, Sperry UNIVAC gave me a job offer—not as much as Texas Instruments, but I didn’t have to move to Texas! I started my career in Paul Wood’s group

working on a debugger for the OS16 16-bit operating system which was used on the UYK-20. That transitioned into the UYK-44 executive tool suite.

My team then designed and built a Relational Database Management System (RDBMS) for the UYK-43. That project sent me to Japan twice to deliver and teach a 43RDBMS class.

Later I did Independent Research and Development work on the Portable Operating System Interface (POSIX) operating system. After that I moved to Pam Johnson’s Tools and Process group.

One tool I supported was a management tool for CM called PCMS. That kept me busy for years. While supporting PCMS I learned a whole lot about CM.

When Lockheed Martin announced the closing of the Eagan location and people started leaving the building, I wore two hats, tools and CM, for most projects still in Eagan.

After the Lockheed Martin Eagan location closed, my next stop was a CM position at Thomson Reuters which lasted for six years until a major reorganization showed me the door.

Fortunately, Product Development Associates (PDA) Engineering under Tony Pascuzzi had a need for a tools guy. That allowed me to complete my 42-year computer engineering career

working with several ex-Lockheed Martin people. I officially retired in May 2023.

Now I have time to volunteer on the VIP Club board! Tenner Thompson

3. Career Summaries - V

3.1 Roy Valentini, 1967-2004.

Over thirty-seven years of experience in Navy weapons, information

management, command and control, and communications systems. Experience

spanned design/development, test/integration, production and life cycle

support. Experience gained in Anti-Air Warfare (AAW), Surface Warfare

(SUW), Strike Warfare, and Anti-Submarine Warfare (ASW). In the 37 years

at Lockheed Martin [formerly Loral/Unisys/Sperry], held various positions,

both technical and management. These positions were Acting Vice President

of Business Development, Director of C3 Systems Business Development,

Director of Naval Systems Business Development, Director of Defense

Information Systems (DIS) Business Development, Director of Navy and

International System Engineering, Director of Undersea Systems Business

Area, Director of Undersea Program Management, Program Manager of Undersea

and ASW Programs, System Engineering Manager, and various system and

project engineering positions.

CAPABILITIES

Anti-Submarine Warfare - System Integration/Test

Anti-Air Warfare - Business Development

SUW - Acquisition Management

Strike Warfare - Program Management

Over-The-Horizon Targeting - Engineering Management

Submarine/Surface Combat Systems - Proposal Management

Information Management Systems - Strategic Planning

Command and Control Systems - Operations Planning

C4I Systems - Program Planning

Weapon Systems - Program Development

Hardware/Software - Risk Management

System Engineering - Life Cycle Management

EXPERIENCE

Director, C3 Systems Business Development, 2000 - 2004

Responsible for business development, marketing and sales for Communications

Systems for shipboard, air and land platforms and land based Air Defense

Command and Control Systems. The responsibilities were for both domestic

and international systems. Responsibilities included managing sales/marketing

managers, discretionary resources, program qualification and proposal

development with orders of $100M per year and budget responsibility

for $4M. The domestic marketing efforts were to the Surface and Submarine

Navies, the Naval codes of NAVSEA and SPAWAR, all the Navy labs, Air

Force Systems Commands, and a multitude of Platform/System Primes. The

foreign Navies covered were Germany, Spain, Greece, Egypt, Turkey, Japan,

Taiwan, and Australia.

Acting VP, 6/2001 - 12/2001

Business development, marketing and sales for Lockheed Martin Tactical

Systems. The responsibilities were for both domestic and international

systems. Responsibilities included managing sales/marketing directors,

discretionary resources, program qualification and proposal development

with orders of $625M per year and budget responsibility for $100M.

Director, DIS Business Development, 1991 - 1996

Responsible for the business development, marketing, and sales to both

U.S. and foreign Defense Agencies/Services. Responsibilities included

managing 8 sales/marketing managers, discretionary resources, and proposal

development with orders of $250M per year. The domestic marketing efforts

were to the Surface and Submarine Navies, the Naval codes of NAVSEA

and SPAWAR, all the Navy labs, Air Force Systems Commands, and a multitude

of Platform/System Primes. The foreign Navies covered were Germany,

Spain, Greece, Egypt, Turkey, Italy, Japan, Taiwan, Australia, and Canada.

Director, Navy & International System Engineering, 1989 - 1990

Responsible for the system engineering, project management, and technical

development of all Navy and International systems programs. Directed

a project team of 60 direct report engineers and over 700 matrix engineers.

The Navy programs consisted of SQQ-89 Basic/Improved, AN/BSY -1/2 Combat

Systems, CCS MK-l/2 Combat Systems, Trident Engineering and Integration,

ASWOC Midterm, NAVMACS, Surveillance Direction System, Ship Systems,

TEAMS, Combat Direction System Simulation, Automatic Direction Finder,

and Over-The-Horizon Targeting. The International programs consisted

of Greek, Egyptian, Turkish, and Israeli Submarine programs, German

F123 Frigate, Canadian Patrol Frigate, Canadian Tribal Class Modernization

Program, and Thailand, Egyptian, and Turkish Coastal Defense Systems.

Director, Undersea Systems, 1985 - 1988

Responsible for all technical and financial [orders, revenue, gross

margin and profit] aspects for the Underseas Business Area with direct

control of Program Management, Engineering, Financial Control and Marketing.

Responsible for Underseas programs for both the SSN Attack Class and

SSBN Trident Class submarines which included hardware/software systems,

test/integration and ILS efforts. Had control of contract values in

excess of $200M with over $50M of revenue per year. Was chairman of

the Underseas Business Area team whose responsibility was to pursue

new business.

Director, Undersea Program Management, 1984

Responsible for the management of the Undersea Program Management organization

reporting to the director of Underseas Systems. Control of ten program

managers with accountability for $40M of revenue.

Program Manager, ASW/Undersea Programs, 1979 - 1983

Program Manager for the Combat Control System MK-1, SUBACS and Over-

The-Horizon Targeting programs with contract values in excess of $100M

and over $20M of revenue per year. Directed the development, production,

test/integration and delivery of hardware and software systems for the

SSN 594/637/688 Attack Class Submarines. Also, responsible for all proposals

for these programs.

Manager, System Engineering, 1974 - 1978

Held several System Engineering Manager positions in various disciplines

including hardware and software design/development, system engineering,

system test and integration, and quality assurance/configuration management.

Directed organizations varying in size from 15 to 40 people for Navy

projects including Trident, SSN Combat Systems (ASW), Surface Ship Command

and Control Systems (AAW, SUW), Moored Surveillance System, SOSUS, TFCC,

NAVMACS, and SSN ELINT.

System Engineer, 1967 - 1973

Held several engineering positions including System Engineer, Project

Engineer, Applications Analyst, Scientific/System Programmer. These

positions were on Navy projects in ASW, Submarine Combat Systems, Surface

Ship Command and Control Systems, and International programs.

EDUCATION

BS Mathematics, St. Cloud State University, St. Cloud, MN - 1966

Several post graduate courses in Business, Management, Finance, technical

subjects, and proposals.

![]()

3.2 Earl Vraa, 1961-1991.

I graduated from Northrop University in 1960 with a BS in Aeronautical Engineering. I also was a licensed Airframe and Power Plant mechanic with an A&P license. In addition, I had a private pilot’s license with over two hundred hours of flying time with some “hood” time. My intention was to either get a job with one of the airlines as a flight engineer as my vision was not 20/20 and that was a commercial pilot’s requirement at the time. Flight Engineers could wear glasses.

I begin to look to my future. The Space Program

was gaining momentum and I was working at AirResearch on the

environmental system of the Mercury Program that Alan Shepard

piloted. That gave me some insight into the system requirements.

Computers appeared to be an interesting area to investigate as

computers were influential in the success of the programs. I wanted

some computer experience for the space program. My thought was that

a few years of experience with computer applications would enhance

my resume. This led me to interviewing “space related” companies and

somehow Remington Rand Univac (RRU) popped up.

The rest of my story is the IT Legacy Our Stories for

October 2023,

4. Career Summaries - W

4.1 Sam Walzer, 1954-1994.

I worked for ERA from June 1954 until I retired from UNISYS in January

of 1994. My responsibilities varied in all those years starting from

"SORTING and Validating" ferrite cores for the memories of various systems.

I spent three different tours on Kwajalein Island; one month in 1964,

three months in 1965, and then 49 months from July of 1968 through August

of 1972. All three tours consisted of operating and maintaining the

Target Intercept Computer system. Also, during my assignment to ISRAEL

I worked on a hybrid communications system, I'm not sure of the project

ID number.

If I can be of any additional help, don't hesitate to ask. Sam ![]()

4.2 Don Weidenbach, 1946-1976.

I graduated as an electrical engineer from South

Dakota State in June, 1943. Shortly thereafter, I reported for duty

to the Army Signal Corps where I served as a Communications Officer.

Upon completion of training I spent 38 months in the Philippine Islands.

After discharge in the fall of 1946, I came to the Twin Cities looking

for work. The State Employment Office listed a new company in St. Paul

that was hiring engineers for classified military work. I was interviewed

and hired by Engineering Research Associates (ERA) in November of that

year. The company was less than a year old and had about 100 employees.

My first assignment was on a communications project for the Navy.

My job was to design a ring counter using miniature thyratron vacuum

tubes. It was my introduction to digital circuitry and to gas tubes.

I was on the project for about a year. After the design was completed

it went into production and over 100 units were built. That was a big

job for ERA in those days.

My first computer project was a special purpose machine for the

Navy, Demon I. The project was headed by Jack Hill. Some of the engineers

I worked with were Frank Mullaney, Emmet Quady, Warren Burrell, and

Ward Lund. My assignment again was ring counters, but these were much

faster, using 6J6 dual triode vacuum tubes. It was a crash project.

Much of the circuit and memory design [magnetic drum] had been done

on an earlier project. We had only six months to do the job, so long

hours were the norm, but we made the schedule. A few months later I

was called to the front office by Ralph Meader and asked if I would

go to Washington D.C. for six months to “baby sit” a computer

[Goldberg] that had been shipped earlier and had some problems. I agreed

to go and was asked if I could leave the next day! As I was single that

was no problem. After three months and some design changes to the drum

memory system the machine was working well and I was able to return

to St. Paul.

I was next assigned to Jack Hill's memory development group.

My first job was to design a new magnetic read/write head which had

ferrite core material rather than steel laminations used in earlier

heads. It also involved designing new read/write circuits. These heads

were used on most new projects that used magnetic storage drums and

were a big improvement in cost and performance over the earlier models.

The writing circuits were now able to record continuously rather than

writing one cell per drum revolution as was done previously.

In 1952 ERA became part of Remington Rand. We thought that now

that we were no longer a small struggling company we could take on the

big boys---IBM, NCR, you name it. We could even put Eckert Mauchly in

their proper place, wherever that was! Control Data and Cray Research

didn't exist yet, but Seymour was down the hall busily working on the

1103. A friend of mine who was working on the instruction manual for

the 1103 often complained at lunch that Seymour wouldn't take time to

talk to him so how could he write the manual! Somehow he got it done.

In 1953 the company won a small contract [$50K] from a Chicago

mail order house, John Plain, to design and build an inventory control

system. John Plain was using IBM punched card tabulating equipment which

we were now going to replace with modern electronic equipment! I was

appointed Project Engineer and the machine was called Speed Tally. To

keep costs down and shorten delivery time we used Univac 1103 hardware

wherever we could. The down side was that the manufacturing cost of

this hardware was not cheap. We had a considerable overrun before the

system even shipped! An interesting and challenging task was modifying

a Remington Rand 10 key adding machine so it would have electrical readout.

Ten of these were used as input/output terminals to the computer. John

Plain used the machine for over a year and then went back to their old

card system which was eventually replaced with an IBM 650. We did not

replace IBM, but we gained some valuable experience in working in a

commercial environment.

Our next attempt was the Univac File Computer. I was assigned to this

program at its start in 1955. Robert 'Bob' Erickson was the head of

the project. There were four principal designers: Gerry Williams [magnetic

storage], Bob Wesslund [arithmetic unit], Jim Wright [control], and

me [input/output]. We were known as the 4 W's. {Editor's note: Shown

at the right in a 2009 photo are Gerry, Jim, and Don. Bob had passed

away in 2008.}

Our next attempt was the Univac File Computer. I was assigned to this

program at its start in 1955. Robert 'Bob' Erickson was the head of

the project. There were four principal designers: Gerry Williams [magnetic

storage], Bob Wesslund [arithmetic unit], Jim Wright [control], and

me [input/output]. We were known as the 4 W's. {Editor's note: Shown

at the right in a 2009 photo are Gerry, Jim, and Don. Bob had passed

away in 2008.}

My job was to design the interface for the Remington Rand 90

column punched card unit. This proved to be a challenge in many ways,

one of which was the reliability of the card unit. Later other I/O devices

were added to the computer. One interesting thing about the File computer

was that it started out as vacuum tube machine but before the design

was completed transistors were used in the newer parts of the machine.

Transistors were still not very reliable, so we had our share of problems

with them. Two models of the File Computer were designed and over 180

systems were built. The Federal Aviation Agency (FAA) used them at major

airports for air traffic control. This was the beginning of a long series

of contracts with the FAA that went on for many years. Northwest Airlines

used File Computers for airline ticket reservations, a pioneer in this

application. Douglas Aircraft used them in a number of their plants

for inventory control. I spent several months at their DC-8 plant in

Long Beach, California during the installation and checkout of the first

computer. All of their data was stored on 90 column punched cards, so

we got a lot of experience reading cards. I also helped install systems

at First National City Bank in New York, Eastern Airlines in New York,

and Northwestern National Life Insurance in Minneapolis.

In 1959 I was assigned as Manager of the Athena project reporting

to Arnie Hendrickson. Athena was the ground guidance computer for the

Titan I ICBM. At the time I joined the project, the first unit had been

delivered to Cape Canaveral for testing with the BTL/Western Electric

radar and the Martin missile. Shortly after joining the project, Arnie

and I took a trip to Florida to meet our field engineers and programmers

and observe the system during a test shot. I remember two things quite

vividly about that trip. First, it was raining very hard when we landed

so we stopped at the first gas station/convenience store and bought

rain coats. We used them quite a bit while we were there. Secondly,

missiles were not very reliable in those days, so we went through several

days of countdowns and scrubs before we saw the live test. In the meantime

we saw another missile blown up shortly after launch on an adjacent

pad. It was an exciting time and nice to see our equipment function

without error. While I was on the project we designed a second model,

and built computers for all of Titan missile sites. Athena was the first

transistorized computer that Univac delivered to the field. It had extremely

high reliability standards and considering that transistors were so

new it really was a challenge to achieve these goals. The system had

an unblemished record of over 150 launches without a malfunction. Our

group also did the programming of the computer, including satellite

launches from Cape Canaveral and Vandenberg AFB. Included were the Echo

passive balloon, Telestar, the first communications satellite and Tiros,

the first weather satellite. During the early part of the program our

Air Force technical liaison officer was Captain Gerald Probst, who later

joined the company and eventually became the CEO of Sperry Rand.

The group's next assignment was to design and built the prototype

ADD missile borne guidance computer for the Titan II missile. This unit

occupied less than two cubic feet of space yet had to do the same job

as our Athena computer. It was a new experience for us, as we had only

done ground based equipment up to that time. Using discrete components

[there were no integrated circuits yet] we crammed the parts into cordwood

encapsulated blocks about the size of a small eraser. The component

leads were cut off and then spot welded to miniature printed circuit

boards. The computer had a thin film main memory. We built several of

these prototypes, gaining much experience in high density packaging.

In 1962 I was assigned as Manager of the Nike Zeus project. This

was a ground based computer which controlled the

Nike Zeus anti-missile missile. We were a sub-contractor to BTL/Western Electric

who had the prime contract with the Army. The first model, the TIC (Target

Intercept Computer) was built from foam encapsulated building blocks,

about two inches square in size. The blocks were assembled on a flat

pan like chassis and then connected by machine wire wrap, a new technique

which had just been developed. Later we designed a second computer called

GPDC and built a number of them for test sites at Bell Labs, White Sands

Proving Grounds and Kwajalein Island.

In 1962 I was assigned as Manager of the Nike Zeus project. This

was a ground based computer which controlled the

Nike Zeus anti-missile missile. We were a sub-contractor to BTL/Western Electric

who had the prime contract with the Army. The first model, the TIC (Target

Intercept Computer) was built from foam encapsulated building blocks,

about two inches square in size. The blocks were assembled on a flat

pan like chassis and then connected by machine wire wrap, a new technique

which had just been developed. Later we designed a second computer called

GPDC and built a number of them for test sites at Bell Labs, White Sands

Proving Grounds and Kwajalein Island.

In 1963 my group was tasked to design the computer for the Nike

X Anti Ballistic Missile. This system used many cutting edge technologies,

including the very fast Sprint missile guided by a phased array radar

[no moving dish, electronically steered beam], and a high speed multi-processor

computer with 200 nanosecond thin film memory. We completed the first

computer in 1967 and continued on with this project until the SALT agreement

shut down ABM activity in 1969.

In 1970 I became Manager of Systems Design in the Engineering

Development Lab in Plant 8, Eagan, reporting to Carl Glewwe. I worked

at that location until my retirement in December 1976, having completed

thirty years with the company. It was a great time to be in the computer

business and I remember fondly the many great people that I was associated

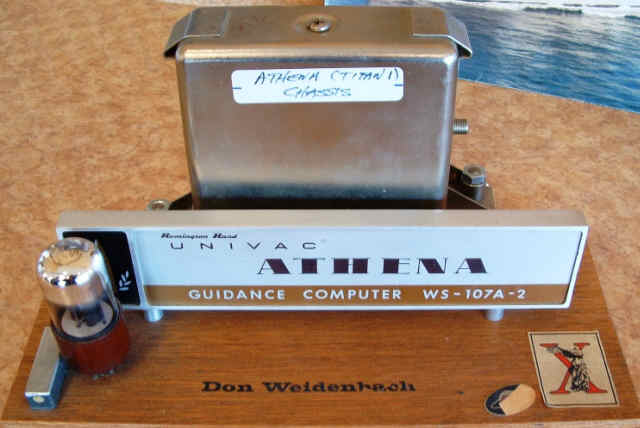

with.{Editor's note: Don was given the desk mount shown here at his

retirement party. It has an Athena module, an Athena vacuum tube, a

Nike X sticker, and ERA sticker - partly peeled off.}

![]()

4.3 Eldon Weinhold, 1967-200x

I have had a long and varied career starting with

UNIVAC, Sperry UNIVAC, Sperry, UNISYS, Paramax, UNISYS, Loral, and Lockheed

Martin.

I graduated from Iowa State University in November, 1967. I was

hired by Joe Graham at Univac to become a Field Engineer in Building

#6 on University Ave., St. Paul. I spend almost 7 years in Field Engineering

working for Joe, Gerry Grosse, and George Fedor. I started out working

in the Military Equipment Test Center (METC) at Plant #2, attending

Univac training classes [the training department was in the guard building

at Plant #2], worked on the checkout floor in Plant #3, and Eslingers

after work. The first phase of the Eagan facility [Plant #8] had just

opened and there were maps drawn on how to find it from the Midway Area.

My first field engineering trip was to Bath, Maine - the Bath

Iron Works to work on an IDAC and OSI on the West German DDG SATIRE

Ship Program. I had never seen an IDAC or OSI before and Joe gave me

manuals to read on the airplane. I was to be in Bath for 2 weeks and

ended up staying 22 months. I worked on three West German DDGs and then

went on to the DLG-16 Class NTDS Modernization program working on the

DLG-17, DLG-21, and DLG-24. Besides working the installations on each

ship, I rode each ship up to three consecutive days at a time on both

builder’s sea trials and Navy sea trials in the North Atlantic.

Weather in the North Atlantic can get quite rough in the winter and

I have seen operators with seat belts on in Command Information Center

(CIC) because of the extreme pitch and roll. I left Bath in May 1970

because the shipyard went on strike and the Navy sent all field service

people home.

Next in 1970-71, I worked on a large communication switching

system, the SSQ-59. There were only 2 systems built, and both were checked

out on the floor in Plant #5. The system included about 18 large switching

cabinets, a 1218 computer, 2 operator control consoles, and a 1004 card

reader/printer as the load device. Yes, the operational system actually

loaded from two boxes of punched cards. I worked both system installations:

the Mt Whitney, LCC-19, in Newport News, VA then the Blue Ridge, LCC-20,

in Philadelphia, PA then went on Navy sea trials on the Mt. Whitney.

The project engineer was John Fritz.

I went on-site for almost 3 years at the RCA facilities [now

the LM-MS2 facilities] in Moorestown, NJ in March of 1971 to work on

the initial development of the AEGIS program. I had three very early

S/N AN/UYK-7 computers and installed every 3-level wire-wrap field change

that was put in the AN/UYK-7 until the whole CPU and IOC chassis were

replaced. The system also had the 1840 vacuum chamber magnetic tape

units. The first software development system lab also had a CRPI (Card

Reader, Punch, and Interpreter). I trained many RCA field service personnel

and went with them to Long Beach and Oxnard, CA in early 1974 to work

the first AGEIS installation aboard the USS Norton Sound.

My last field engineering trip in 1974 was also a unique trip.

I was set to transfer out of field engineering the next week and there

was a request for engineering services at a commercial site in Baltimore,

MD. Since I was the only one in town, I was asked to go out on Thursday

night, work Friday and come home. I went to Baltimore and on Friday,

was told that the people couldn’t support me until Saturday. By

Friday afternoon, I had received a call from St. Paul saying that they

needed someone to checkout a AN/UYK-7 in a MATCALS shelter at Patuxent

(PAX) River on Monday morning. I bought some extra clothes, worked Saturday

in Baltimore and went to PAX River on Sunday. The PAX installation went

smoothly. The shelter was right beside an aircraft carrier practice

runway and I got to watch aircraft fly in and snag the wire as if they

were doing a carrier landing.

In 1974 I transitioned to a System Engineering role on a new

NAVELEX program called NAVMACS (Navy Modular Automated Communications

System) that Sperry won by responding to an RFP with a proposal written

by a small number of individuals. It was a follow-on system to an earlier

system development called BSS (Broadcast Screening System). NAVMACS

was an automated message processing system for Navy ship communication

systems. The communication circuits processed were four Fleet Broadcast

channels, four Full Period Termination channels and a CUDIXS channel.

The program ran for about 15 years and NAVMACS became a family of different

sized systems using one, two, or three computers depending on the size

of the ship and number of remote terminals required. NAVMACS was the

biggest user of AN/UYK-20, AN/UYK-20A, AN/UYK-44, and AN/USQ-69s - and

was the first user of the serial interface cards in those computers.

It was a large software development program for Sperry as well as the

hardware sales. My last trip on the NAVMACS program was another great

experience. I flew on a COD flight from North Island, San Diego about

150 miles out in the Pacific and landed on the carrier USS Enterprise.

I rode the carrier ship for 4 days and was catapulted off on a COD flight

back to San Diego. Various NAVMACS Program Managers included Dave Kolling,

Bob Jacobsen, and Bill Rogers. Bill Kailey was the first Project Engineer.

Next I spent 3 years as a System Engineer on a

classified program called CP-256 in Camarillo, CA. The program moved

back to Eagan at the end and was cancelled by our customer.

I transitioned to Maritime Surveillance in 1994 and worked communication

system engineering on the Navy P-3C AIP program and a similar system

called UIP for the four Norwegian P-3C aircraft. Tasks included the

integration of a new ICS, a new UHF SATCOM DAMA radio system, a four-antenna

combiner system and a new Tactical Data Processor called the OASIS.

This project has meant many trips to PAX River, MD; Greenville, SC;

and Clearwater, FL; many vendor sites and even one trip to Bahrain in

the Middle-East.

I am working now on the design and integration of Link-16/ITP

and new architecture into the AIP system. It is now 2007, I am still

working AIP and the final aircraft, aircraft #72, is in production in

Greenville, SC. This program has been challenging in that the military

has changed over the years and now there is very little mil-spec hardware.

Everything is Commercial Off The Shelf (COTS) because the Navy wants

the latest technology all the time. Obsolete hardware is one of the

biggest problems on the program. Many subsystems have been redesigned

and replaced during the program because of the long program duration

and the advance of technology.

I have seen so many changes over my years at work. Starting on

642-B and 1218 computers and now working on chassis that have many single

board computers in one unit. One of the biggest changes was the introduction

of the Personal Computer. I don’t know how work got done before

without them.

![]()

4.4 John Westergren, 1972-2012

My career with Lockheed Martin and its heritage

company, Sperry Univac started shortly after I enlisted in the United

States Marine Corps in 1966. Little did I know that when I was fortunate

enough to be assigned to Basic Electronics School and then offered to

extend my active duty commitment to a total of six years for something

called “computers”, would it provide me my future career:

as my lovely wife has always said “I’m more lucky than good”.

I ended up receiving training on the Univac CP-808 at the Plant

2, W. Minnehaha facility and for the next five years maintaining the

system in California and Okinawa. I was hired into the Field Engineering

department in 1972 through the recommendation of Dale Reizweitz and

Jim Sprecher, working for Paul Hove and Jerry Gross and with some of

the best troubleshooters in the world like Dan Gebhart, Mike Mullen,

and Roger Engel. The next four years I worked and played with this team

providing world wide technical support for any and all Univac computers

and peripherals. For a twenty-something kid, this was the most fantastic

job a person could want; traveling on full expenses all over the world

working with/for some of the legends of that time: Rip Anderson, Lowell

Benson, Lew Carlson, Jack Lavers, John Markfelder, Ole Olson, Don Vizanko,

just to name a few. Is it any wonder why I am what I am today with mentorship

like that.

This also provided me the opportunity to work on the companies

leading edge products like the AN/UYK-15, this first “mini computer”;

AN/UYK-23, one of the first tactical airborne computers; the AN/UYK-20,

the Navy’s first standard mini-computer; and systems where these

computers are used like NAVMACS, the Navy’s first digital message

processing system; counter artillery/counter mortar system; SURTASS,

the Navy’s passive submarine listening system; and CATTCAIR, the

Navy’s first automated landing system for aircraft carriers –

just to name a few. Because of this excellent background in how our

computers were utilized in systems, I joined Design Engineering as the

Project Engineer for the AN/UYK-20 working for Bob Jablonski and working

day-to-day with our customer NAVELEX 570, CAPT Chuck Hager, Al Smyne,

and Ron Goodling along with the Univac Program Management team of John

Johnson and Manny Block. These individuals and all of the other named

and unnamed men and women on these programs were instrumental in allowing

me to grow in the knowledge of the business of providing the best products

to the finest military in the world. This is also where I started gaining

a great appreciation for our ability and difficulty with manufacturing

products for use within the military and maritime environments.

As I gained more experience working with customers, I started

taking field assignments like Field Engineering Supervisor in San Diego,

System Engineering representative for the 6977 Telecommunications Project

for the Israeli Air Force in Tel Aviv, Israel and Canadian Operations

Engineering Manger at our Winnipeg, Manitoba, Canada manufacturing facility.

This was a growth period for Canadian Operations and I was extremely

fortunate to work for Gerry Smith, Glen E. Johnson and Ron Guimond while

having some of the best engineering talent in the world working for

me: Ken Buchler, Ed Pogorzelec, Albert Cerqueira, and Neil Williams.

I was also extremely proud to hire some of first female engineers in

Sperry, Joan Coughlin and Kaye Tsang. This group became a highly respected,

extremely capable group of Engineers that I’m very proud to have

been associated with. Working at one of the manufacturing locations

also started exposing me to the likes of Bob Faust, Myron Lecy, and

Gordy Erickson -just to name a few of the manufacturing elite of the

company. They taught me never to think too much of myself, but learning

that when working together as a Team, there probably isn’t anything

you can’t accomplish.

Returning back to the Twin Cities to start working on the newly

won AN/UYK-43 project with the responsibility for transitioning that

design to the factory, I was able to work with another great Design

Engineering Team with folks like Tom Krocheski, Dave Kaminski, Gary

Hokenson, and Paul Richardson. I was also able to work with the group

on the “other side of the wall” lead by John Sundstrom and

Art Tearington while all of this was watched over by Mike Snodgrass:

not a crowd for the faint of heart, but extremely rewarding. This experience

also provided the next opportunity of leading the AN/ UYK-44 Embedded

Engineering Team where traveling with Mike Meyer and Ed Spiess let me

hone my skills playing cribbage on those long flights by winning large

sums of money (that’s the way I remember it). I would be extremely

neglect if I didn’t mention that it was during this time when

I was lucky (remember) enough to settle down and marry my lovely wife,

Pat Mansur, who was also a Sperry employee. All of the individuals,

following and previously, mentioned have subsequently expressed their

surprise and condolences to her on my luck and her choice.

It was on one of the aforementioned trips that Don Dunn offered me the

opportunity to enter the dark world of Program Management for the UYK-43

program: I’ve only fondly looked back. Here again was a tremendous

opportunity to learn from Jerry Nickell and Harry Morrison the subtleties

of customer intimacy, organizational mediation, and ability to stand

in front of senior management with a straight face and unwavering voice

proclaiming that “there is no problem!” I was also fortunate

enough to work with some great finance wizards like Jeff Herman and

Lee Meyer who taught me to add/subtract, never to use the same number

twice and that you can explain a $150M program on one sheet of paper

(size 16 font) along with guys in Quality Assurance like Jim Kzaley

and Chuck Proshek who never let me forget that Quality (in everything

you do) is #1.

There was a three year hiatus working away from the company with

Wayne Culbreth and Keith Myhre on the new technology of Radio Frequency

Identification (RFID) and then Emmett Johnson as a Manufactures Representative;

just long enough to start the vacation clock over again. At the request

of Clyde Allen, I was the first employee hired by Loral in Eagan to

be the UYQ-70 Program Manager. This was a tough act to follow, but the

Team started by Tom Erickson and Paul Thierry was reinventing the way

we developed products and did business with the Navy. This continues

to be extremely rewarding. This Team has taken a program, that in it

infancy, was only going to be a small, couple million dollars a year

program to the largest single program in the history of our “division”;

it keeps the lights on and pays the bills. It is one of a long line

of successful, profitable programs that we are recognized for throughout

the corporation. It started with folks like Harvey Taipale, Steve Palmer

and continues with the next generation with individuals like Allison

Hernandez, George Kaniamos, and Jeremy Sommer. The company is in intelligent

and capable hands.

As you might be able to tell, sure it’s the job, the opportunities,

and the products, but much more so, it’s the people: the customers

I worked for and all the other UNIVAC/Sperry/UNISYS/Loral/Lockheed Martin

employees that I was extremely fortunate to work with. Today, Lockheed

Martin is practicing the principles and attributes of Full Spectrum

Leadership; an excellent and worthwhile approach to business. These

attributes were alive and vibrant throughout my entire career with each

of the individuals mentioned and many more. People make an organization

great; people challenge other people to grow and be better; simply said, “It’s

the people!” and I’ve been one of the most fortunate and

lucky people I know: I agree with my wife. ![]()

4.5 Tom Widenkopf, 1964-1991; My Work Experience.

In 1964 I joined the new commercial division of Univac in Roseville

MN as a hardware engineer. The technology was discrete components such

as diodes, transistors & resistors. Our first personal workstations

were 8-bit Tandy Radio Shack TRS-80s.

My first major job was in the development of the 418-III communications

computer in the late 1960s. It featured a large maintenance panel that

displayed, via many ribbon cables to big selector switches, most of

the registers in the machine.

In the 1970s & early 1980s I supervised the unique development

or modification of peripherals such as disk subsystems & array processors

for specific customers. This required travel to their sites in North

America, Western Europe & Tokyo. It was not boring as the technology

improved rapidly, but I found satisfaction in working closely with each

customer. Often there were several small concurrent projects at various

stages of development, from planning, design, build, test & site

installation. I took lots of management training classes & received

an Excellence Award.

For several years I visited my alma mater the University of Illinois

2 or 3 times per year to interview students, award scholarships, etc.

In one gratifying case we hired a very bright intern who had 14 other

job offers.

As a project manager in the late 1980s my group was challenged to develop

an equipment that would operate continuously for at least ten years,

even though components failed & were replaced. Called a Record Lock

Processor, it functioned as a traffic cop for shared files on disk subsystems

in multi-computer transaction systems. After elaborate testing it was

delivered on schedule & within budget to an airline customer in

Japan.

I accepted an offer for early retirement during the Halloween snowstorm

of 1991. In review, I cannot think of a more dynamic work experience!

I worked with many highly motivated people. All development is self

development. If it is to be, it is up to me. Wow! Tom W.

![]()

4.6 Monte Widdoss,

The USS Los Angeles is moored at the SEAFAC static site as part of ESCAPEX

2006. Photo courtesy of U.S. Navy by Mass Communication Specialist 1st

Class Cynthia Clark. There are two things about this photo in a 2006

SAIC article that were of interest to me:

This was the first exercise in over 40 years to test how well crew members

could escape from a crippled submarine submerged at depth, and the first

time ever from a nuclear submarine. The submarine, USS Los Angeles SSN

688, [the hull number] was very important to me in my early career [circa

1973] working with the submarine community of the US Navy when Anti-Submarine

Warfare (ASW) was very important to this nation then facing a major

Soviet submarine threat. I led a team at what used to be Sperry Univac

to a highly competitive, large contract to develop an integrated Combat

Control System for the lead ship (USS Los Angeles) of the SSN 688 Class

of submarines. [The Navy refers to all the ships built to the design

of the lead ship to be in that "class".] The result was a group at Sperry

Univac [now part of Lockheed Martin] that continues today to support

the current versions of submarine combat control systems some 30+ years

and over $800M later. Damn! Am I old. Monte ![]()

4.7 Mike Wold, 1970-74 & 1984-1997.

I started my career at Sperry Univac in June of

1970 after serving in the Navy as the head “pork chop” on

an oiler as a member of the Tonkin Gulf Yacht club. I interviewed at

IBM and Honeywell but really liked the “tennis shoes and T shirt”

culture at Univac. I felt honored to be working with these very informal

and often humorous people who were the founders of the computer industry

in the country. I spent a few months in Navy Systems in their tracking

group and then a number of us were transferred to the expanding Air

Traffic Control group. We had won an R&D contract from the FAA called

the ARTS Enhancement Program and I got a chance to work with some really

smart people who were developing advanced air traffic control technology,

e.g., conflict prediction, radar tracking, etc. What I remember about

those days was the “work hard, play hard” culture in the

ATC group. It was not unusual to work all night long at the test bed

at the airport and then come in for a full day of work the next day.

It was also not unusual for us to gather on Friday afternoon at the

Valley Lounge [also called “The Open” since they did not

take down their “Now Open” sign for a couple of years after

they opened]. We not only worked together but we spent a lot of time

playing sports together – I remember being on a softball team,

a tennis team, a bowling team, and a volleyball team. This togetherness

in work and play created a great culture of teamwork. There was nothing

we would not do for one another. There was a great tradition of stopping

everything we were doing if someone stopped by with a question –

and I remember having a lot of questions. In fact I remember telling

my wife that I was not sure I could make it at Univac because I could

not understand the thousands of acronyms. Of course after a couple of

months I could talk in acronym language and confuse all the new people

just like everyone else.

One of my favorite memories from those days was when we were

challenged by our arch nemesis, Hughes Aircraft, on the effectiveness

of our tracking algorithms. In typical Hughes fashion they had gone

to the FAA and told them that they were the tracking experts and why

are you working with those Midwestern farmers for your tracking technologies.

[What they did not know is that we had very smart farmers at Univac!]

The FAA felt forced to listen to Hughes so several of us went out to

the Hughes site in California with the FAA for a “showdown”.

Unfortunately for Hughes their demo was a big flop and ours went perfectly.

Not only that but instead of being good hosts they went out of their

way to insult us. They picked up the FAA representatives who were staying

at the same hotel and never invited us along. The next day we had a

meeting and I remember when their big honcho came in the room all the

Hughes people actually stood up. It reminded me of when some dictator

graces the room with his presence and all his stooges salute. The executive

apologized for the poor demo and explained it was just a minor problem.

Then he asked, “Well, what is the next step for us to be able

to work for the FAA on tracking?” All of us Univac folks just

about bit our lips to keep from laughing when the head of the FAA delegation

said, “I assume that you know that Univac is our prime contractor

for all our R&D work so you will have to meet with them if you want

to get on the program”. Needless to say we saw no more of Hughes

on the ARTS Enhancement Program! To this day, the Eagan operation is

known in the FAA for their tracking expertise, which actually originated

in the great work that the engineers did on the NTDS program.

I left Univac with mixed emotions in 1974 since I really liked

the people and our bosses. We had gotten about 5 years ahead of the

FAA in our technology and I decided to try out my wings with a systems

consulting company called Intech. I later ended up at the State of Minnesota

and in 1984, 10 years later, I came back to what was then called Sperry.

One of the great cultural features of the company was the way they welcomed

former employees back with open arms. Some companies look at an employee

who leaves as a disloyal person and burn the bridge as they leave. This

was never the case with our company and I was welcomed back with open

arms. I heard that this cultural value originated back when so many

people left in the 1960’s to go to Control Data and other emerging

computer companies. Our company decided to welcome back anyone who left

and if fact would reinstate their benefits if they came back within

2 years – unheard of in the industry.

I felt I had learned a lot when I was gone, especially about

commercial information systems, information systems design, leadership

and management and was anxious to dig in. After working some R&D

on military air traffic control systems, I took a chance and volunteered

to be the proposal manager for a U. S. Marine radar and tracking system –

the MATCALS ATCS (Marine Air Traffic Control and Landing System Air

Traffic Control Subsystem). We were subbing to Sperry Great Neck and

there were a number of challenges including when the engineers at Great

Neck went out on strike during the middle of the proposal and a couple

of use had to go out there and go through the picket lines and write

much of their proposal. I remember when we won, it was one of the happiest

days of my career. We had not won a lot of proposals and this one, although

relatively small was important at the time. We delivered our parts of

the system on time [I remember sitting in the back of a pickup truck

with snow coming down as we drove Serial 1 up to Shepard Road for testing

just before Christmas.] That brings up another important cultural value

for the company. We would kill ourselves making sure that we never let

a customer down. I can’t remember in all of my time at the company

ever hearing about a system where we did not eventually deliver to the

customer. [Some were so over-run that perhaps it would have been a better

business decision to drop it, but that simply was never an option and

I believe our customers knew it.]

After some proposal work on mobile air traffic control I was elated to be selected to be the director of systems engineering. I had always viewed myself as a system engineer and it was great to be able to work with a couple hundred very talented people in areas such as system design, system analysis, testing, reliability, and testing. The biggest challenge during this time was the “debarment” that occurred and kept us from getting any new work for I believe it was 6 months. During that time we worked as a team to keep from having to lay off people since we knew that eventually we would need their expertise. We leveraged every tool we had including paid and unpaid vacations and made it through keeping our capability intact when the cloud was lifted. What I remember about those dark days is how supportive our customers were. They did all they could to keep us alive during this time. During this time we created the support systems and processes for a very professional system engineering capability and this foundation was useful for many years to come, even after the group was disbanded and went to the various business units.

My next assignment was perhaps the most challenging and exciting of my whole career. I was appointed as the B-2 Program Manager. By that time we were Unisys Defense Systems and we had a number of avionics computers on the aircraft. At the time I came on the program it was still a black program and we lived in a “tank” in the basement. What was great is that my predecessors had taken the opportunity to create a culture behind the two cipher locks that was really unique. It was a small high performance team of really talented people. Since to top management was not “read in” to the program they could not come into our space and they could not be told what we were doing. This gave us a lot of freedom and it was great environment to work in. The biggest challenge was a technical one. The mission of the B-2 had been changed after the initial designs for the computers had already been done and the costs estimated. The new mission required significantly higher vibration and temperature profiles and we were failing the Reliability Development Growth Test (RDGT) while burning up money like it was hay. With the support of our management I decided to stop the testing and take a time out to analyze and fix the problem. The day I announced this to the customer at Northrop Grumman all h--- broke lose. I got a call from an Air Force Colonel who threatened me with nasty things if I did not resume testing. We held our ground and our sharp mechanicals modeled the system and came up with a fix. We also worked with a lab in Maryland and they proved that the stress scenario that the Northrop engineers had created had major errors in it since they had not taken into account the combination of temperature and vibration done simultaneously. Between the redesign and the change in testing we made it through with flying colors. Since we were the first box through the testing on the whole aircraft and because Congress was trying to kill the program, Unisys became a poster child for good performance at Northrop and we won their supplier of the year award. I remember getting calls from program managers from other Northrop subs thanking me and our great mechanicals for proving that the stress scenario was in error. I felt we saved the B-2 program millions of dollars because of our engineering expertise.

After getting a chance to work as a program director for some very interesting programs including Trident, Nexrad, and several others, I was appointed the director of the air traffic control engineering group. I can’t tell you how honored I was to be able to come back to lead this great group of people. A consultant for the FAA once referred to this group at “a national treasure” because of their long history of outstanding performance. There were two big challenges at that time – completing the Common ARTS System for Southern California [the largest metro-plex system in the world at the time] and competing for the $1 billion STARS System which was to replace all the Terminal ATC systems in the U.S. Well, we lost the STARS to Raytheon and this was a sickening blow to us. We had to downsize in a hurry but we were able to transfer a lot of people to other Eagan groups, then we focused on completing the Common ARTS. The folks in ATC worked their tails off as usual and we sold off this system, eventually winning the FAA Contractor of the Year Award. Meanwhile Raytheon fumbled the ball and experienced major delays. This gave us a chance to sell the Common ARTS to the FAA for several more metro-plexes, thereby shutting out Raytheon from ever taking our market for the metro-plexes like Chicago, Northern California, Dallas-Ft. Worth, etc.

In 1997, again with mixed emotions, I left my

friends at what was now Lockheed Martin, but I will always be grateful

that I was provided the opportunity to work with some of the most talented

and dedicated people in the industry [or perhaps any industry]. ![]()

5. Career Summaries - Y

5.1 Dr. Steve Yahr, 1979-

When I came to the training department at Sperry

Univac in June 1979 right from UW-Stout, the training department was

in the basement of Plant 8, MS U0H23. The junior instructor staff was

housed 6-person cubes and the senior staff was in one person cubes.

The managers Dan Newton, Ken Boehm -hardware, and Jerry Engelke - software

had offices. I was in a cube with Duane Domeier, Paul Braden, Jerry

Lundberg and Denny Koewler, all hardware instructors.

One of the more unforgettable characters in the group was Steve

Kloner. Steve [a software instructor] has a very active sense of humor

and assigned each of us a nick name, mine being Extra Crispy, tracing

to my being a hardware instructor and thus, in Steve’s book, addicted

to fast food, in my case Kentucky Fried Chicken [I actually prefer Original

Recipe!!!] One time he came into work after a routine physical. A single,

female instructor, LaJean Wenzel, asked him how it went. Steve replied “well,

my cholesterol is a little high, but the doctor thinks I can cure it

by spending more time with the ladies.” LaJean cocked an eye,

looked at him and said matter-of-factly, “well, you’re gonna

die”. Sorry Steve!!! Another time Steve taught a class at Cold

Lake Alberta in the dead of winter. The drill called for a flight to

Edmonton, change planes and then fly to Cold Lake. Now Cold Lake is

both at the edge of a military test range and our oil drilling area

so the local population is an eclectic mix of locals, military and rough-necks,

and they like their entertainment. On this day the weather was so bad

that the flight from Edmonton to Cold Lake was cancelled and Steve had

to get to his destination on a Greyhound like bus.

I soon learned that this group was very self motivated when it

came to meeting customer needs. This is because we interacted while

teaching directly with customers and could see how our efforts made

customer lives better. Management gave us pretty free rein when it came

to meeting customer needs, and we worked hard on the road to meet all

reasonable requests. It was an exhilarating experience to be given that

much latitude and responsibility – but we thrived on it. Between

classes was “prep” time which was sort of a down time while

you prepared for the next class. During this time if we needed to fix

typos in a student study guide, add an information sheet or a lab, we

did it, anything to help the students better understand the material.

These days of living in a cube where you might not see a customer for

years, and you spend your days constantly revising documents, changing “happy”

to “glad” it is hard to replicate the excitement.

In those days the President and General Manager here, Dick Seaberg,

would come around at Christmas, personally shake everybody’s hand

thanking them for their efforts during the year and wishing them a Merry

Christmas. That hasn’t happened in many years and I think we are

worse off for loosing that sense of connection between the top and bottom

of the organization.

The first piece of equipment I learned to teach was the AN/UYK-20.

While I had been a TV technician and was very sharp on analog electronics

this was the first in depth study of the world digital electronics and

Boolean algebra. The first UYK-20 course I attended was a standard 13

day Operation & Maintenance course taught by Jerry Lundberg. Thru

the first year I learned all the different pieces of a digital computer

and by February of 1980 was on the road in San Diego teaching by myself.

The life of an instructor was busy, lots of time on the road. The managers

kept the schedule on the “magic slate” a 17” x 22”

quad-ruled desk pad. It was called the “magic slate” because

then, like now, funny things kept happening to the schedule, as if by

magic. Thru the guidance of the seasoned instructors (Jerry, Steve Kloner,

Pete Dress) I learned lots and really enjoyed life on the road [fill’er

up, it’s on Mr. Engelke!!] Travel was to Dahlgren VA, San Diego

CA, Oxnard CA, Fullerton CA, Baltimore MD, Washington DC, Newport News,

VA, Bremerton WA, Great Lakes IL, and numerous in-house courses. In

those days we got cash advances to pay for our travel expenses. It was

common to draw $100.00 in travelers checks for each day on the road,

this would pay for hotel, rental car, and meals and we would have a

little money left over. These days if you can find a hotel for under

$100.00 per night it is quite a thing, let alone the extra cost of meals,

car, gas, etc. We taught two and three week courses, always staying

over on the weekends. With hotel, food, and car paid for, we had opportunities

to go exploring. Thus, I was able to take in a multitude of sights,

Washington DC, Civil War battlefields, the USS Missouri [BB 63], air

museums and such as part of business travel, and it was wonderful. During

one trip to the Puget Sound Naval Shipyard I drove to Boeing Field one

fine Saturday for an air show. Planes of all sizes and descriptions

were on display including a FedEx 727, [we got to sit in the cockpit,

and, well – they really had to pry me out!] During the show some

F-14 Tomcat fighters flew in. One pilot’s name was C. J. “Heater”

Heatley, whose aerial photography from F-14 cockpits was one of the

inspirations for the movie “Top Gun” – look for his

name in the credits.

![]()

Part of the “prepping” ritual for each class was

getting all the books we needed for a class. This was no small task

as the operations and maintenance technical manual set for the UYK-20

was seven volumes and a student study guide. All these books had to

be gathered, boxed and shipped before we could leave on a trip. For

years the contact at the warehouse where all this was stored was Marty

Christenson, a really good guy. The boxing / packing was done by Brad

Kowalke and later by Geoff Harms. Normally we would ship all this stuff

to the base we were teaching at, but sometimes had to ship it to our

hotel and ask them to hold it till we could get there. If the class

was in town, part of the end of class routine was getting boxes for

students to ship their stuff home – no easy chore. Now the software

staff had fewer books for their classes, so they would take them along

with on the flight to the destination, paying for excess baggage if

necessary. Poor Steve Kloner was forever “schlepping” boxes

of books here and there.

A favorite noon-time activity for some of the staff was playing

bridge. I had heard of the game but never tried it. Under the tutelage

of Cliff Totten, Gary Hagen, Bob Vogel, Floyd Pratt, Al Stoye and others,

I was soon able to play the game at a level good enough to be invited

to the noon-time

Others of our staff, mainly Duane Domeier, were more into exercise.

It was Duane’s mission to take a walk every noon, especially on

the hottest and coldest days of the year. Only thunderstorms stopped

us. In retrospect the walking was a good way to get away from the desk

for a while and get some fresh air. In the late summer and fall we substituted

target shooting with our bows & arrows for walking. Denny Koewhler

would join in this activity. We had a favorite little area tucked behind

the Corporate Square warehouse [Building E] that straddled the train

tracks. We would set up a target on one side of the tracks against a

hill and shoot from the other side of the tracks. Given that this was

a little used spur, not much disturbed our shooting. One day, however,

as we were practicing we could hear the distinctive chug, chug, chug

of a locomotive. The look on the engineers face as he came around the

corner and saw three guys with bows and arrows watching him was, as

the TV commercials say, priceless!!

Another memorable moment was during the teaching

of a UYK-20 course at Hughes Aircraft in Fullerton CA. I was there over

my 25th birthday, which fell on a Saturday that year, and celebrated

by visiting Disney Land [thank you Mr. Engelke!!]

In August of 1981 I took a nine-month leave of absence to return

to UW-Stout to get a Master’s degree in Education. It was obvious

that the amount of time we spent on the road would make part-time school

difficult, and given the car was paid for, no house, wife or kids, this

was the time to do it. It was during this time that I met my wife Susan.

Given that Menomonie WI is not far from Eagan I kept touch with the

department and we were invited to the department Christmas party. All

the way to the party I kept telling her that these people had very active

senses of humor, they were not like people she had previously met. We

arrived at the party [at the Lost Spur] and descended the stairs to

find Pete Dress. I introduced Susan to Pete who, displaying impeccable

manners, smiled and helped her off with her coat. He then hung her coat

over my head, put a quarter in my hand and said “OK, you can go

park the car chump”. He then took her by the arm and started heading

for the party. As I got the coat off my head I saw her eyes were about

twice their normal size and she had an indescribable look on her face

as this guy she has never met [not her date] is leading her to a party.

I just looked at her and reminded her that “I told you this group

has an active sense of humor”. Later, when Susan and I got married

quite a contingent from the training department turned out. Jerry Lundberg,

a confirmed bachelor, wanted to see if: a) I would actually do it, and

b) if I would sweat. Pete Dress showed up towards the end of the pre-wedding

photo shooting, stood in the back of the church and called “don’t

do it Susan”, “you’ll be sorry”, “I’m

still available!!” It also turns out that Pete had gone to high

school with our pastor, leading to more jokes and good times.

After the wedding, as sort of a wedding present, I got to teach

the only “in-house” UYK-20 class ever taught at the factory

in Clearwater FL, so we had a working three weeks in Florida. Naturally

students far preferred to go to Florida in January for training as opposed

to coming to Minnesota and we had a wonderful time. We went to Disney

World on the weekends, stood in the parking lot to watch the space shuttle

launch and later to watch it return [a glowing spec in the sky with

no sound, but we saw it!!!]

In May of 1982 with a brand-new Master’s Degree I returned

to the training department just in time for the UYK 43 and 44 to come

into production. For the next several years we were busy writing curriculum

and teaching courses on these boxes. In the mean time, the older equipment

kept on working and working so I had a chance to the CP-642 A/B computer

and the 1540 magnetic tape unit at PSNS in Bremerton WA. I also did

quite a bit of teaching on the UYK-44 during this time. One memorable

trip was to San Diego, CA for two weeks in July of 1993 with fellow

instructor and car pooler Glenn Blanchard. We were constantly on the

go when not in class, visiting Mt. Polomar and the Jet Propulsion Lab

in Pasadena where we got a “back stage” tour from one of

our field engineers [yes, we taught the class too!!]. We even found

a John Deere dealership in the middle of the desert [I am a John Deere

fanatic], stopped and took a photo.

During this time we lived in Hudson WI and I commuted with Rich

Rust [who lived in Menomonie, WI] and Marius Procopie [who lived in

Hammond, WI]. Rich was a quiet fellow, but Marius had a lively sense

of humor. He had grown up in Romania and come to the US at the age of

18 to drive a cab in New York City. He made his way to the training

department via an Applied Math degree from UE-Stout. After his wife

got caught by surprise labor and delivered their first child in the

bathroom of their apartment his nickname became “Miseur La Physician”

[the long version] or just plain “Doc” for short.

Over time I had grown bored with teaching individual equipments

and was looking forward for a new challenge. It just so happened that

there was an opening in the Underseas Systems training group working

for Cliff Totten and later for Capt. Bob McCabe. This happy bunch [Rich

Halbleib, Dan Rogers, Doug Jones, Dave Burgwald, Bill Wylde, Pete Dress,

and later Glenn Hashizumi] spent most of their waking hours at SUBSCHOL

in Groton CT teaching the operation and maintenance of fire control

systems [including one Thanksgiving]. It was nothing for us to spend

16 to 20 weeks per year in Groton, always staying at the Ramada in Mystic

CT. Due to the amount of time we spent there, the staff at the Ramada

Mystic got to know us quite well. On time when checking in the lady

at the counter looked up, saw me, and said “Hi Steve, I saw you

were coming and saved your room for you”. This is when I knew

we had been on the road maybe a bit to much!! A favorite place to eat

was Mystic Pizza, later featured in a movie staring Julia Roberts [but