Information Technology (IT) Pioneers

Retirees and former employees of Unisys, Lockheed Martin, and their heritage companies

Spinoffs, Chapter 6

Technology managers and engineers by nature look for new opportunities - this led to creation of many, many companies by people from 'UNIVAC'. Information Technology Pioneers got their start at ERA, ..., etc., then started their own technology companies. Our Legacy was/is a training and learning opportunity for many other companies.

Departure of several management and engineering

personnel in 1957 to create Control Data Corporation (CDC) is documented

in Dave Lundstrom's book, "A few good men from UNIVAC." The

first CDC computer, model 1604 was named because the first CDC plant

was at 501 Park Avenue and some of the computer concepts came from the

UNIVAC 1103, i. e. 1103 + 501 = 1604. The 1604 was a 48 bit

machine, sort of an expansion from the AN/USQ-20 30-bit architecture. It also had a few 24 bit instructions which didn't require memory operands

thus two instructions per memory word.

Departure of several management and engineering

personnel in 1957 to create Control Data Corporation (CDC) is documented

in Dave Lundstrom's book, "A few good men from UNIVAC." The

first CDC computer, model 1604 was named because the first CDC plant

was at 501 Park Avenue and some of the computer concepts came from the

UNIVAC 1103, i. e. 1103 + 501 = 1604. The 1604 was a 48 bit

machine, sort of an expansion from the AN/USQ-20 30-bit architecture. It also had a few 24 bit instructions which didn't require memory operands

thus two instructions per memory word.

"According to CDC's former CEO, Robert M. Price, 'Control Data was the

Apple

Computer of its time; ... there were more than 100 spin-off and other

derivative companies ranging from ...' " Perhaps Mr. Price could

have mentioned that CDC itself was a spin-off. The U of MN

Institute of Technology bought a 1604 in 1963, used by Lowell in

1964 during his Fortran Class taught by Dr. Marvin Stien. [lab]

{Editor's note: A table of 'spinoff' information was printed in the June 23, 1986 St. Paul Pioneer Press and Dispatch citing the Charles Babbage Institute as the data source.}

We've added a few found by our own research; i.e. Northport Engineering before CDC, Printware Inc., and others listed after 1985.

A Commemorative Plaque

On

15 June 2023 Chad Roberts, president of the Ramsey County Historical Society (RCHS)

unveiled a commemorative plaque at the original Engineering Research

Associates (ERA) site recognizing the importance of ERA and

spinoff companies to the local economy and the world. The new

plaque theme is, “ERA and spinoffs’ technologies came to rival

agriculture and mining as a leading industry in the state.”

“From this plant, an enormous contribution was made to human welfare

throughout the world, and the benefits to the local economy are

almost beyond measure.” Don Hall,

author of Generation of Wealth - the Rise of CDC, was the

principal sponsor and emceed the program. After

the plaque was unveiled, Unisys historian Lowell Benson noted a few significant time

points of the ERA through Unisys corporate lineage, including the

Club’s participation in a documentary and volunteerism at the Lawshe

Memorial Museum.

Following Lowell's comments were speakers from ERA/UNIVAC/Cray, Dean

Laurance; Control Data, James McGuire; Cray

Research, John Rollwagen; and Cardiac Pacemakers/St. Jude Medical,

Manny Villafana. This was followed

by audience comments.

On

15 June 2023 Chad Roberts, president of the Ramsey County Historical Society (RCHS)

unveiled a commemorative plaque at the original Engineering Research

Associates (ERA) site recognizing the importance of ERA and

spinoff companies to the local economy and the world. The new

plaque theme is, “ERA and spinoffs’ technologies came to rival

agriculture and mining as a leading industry in the state.”

“From this plant, an enormous contribution was made to human welfare

throughout the world, and the benefits to the local economy are

almost beyond measure.” Don Hall,

author of Generation of Wealth - the Rise of CDC, was the

principal sponsor and emceed the program. After

the plaque was unveiled, Unisys historian Lowell Benson noted a few significant time

points of the ERA through Unisys corporate lineage, including the

Club’s participation in a documentary and volunteerism at the Lawshe

Memorial Museum.

Following Lowell's comments were speakers from ERA/UNIVAC/Cray, Dean

Laurance; Control Data, James McGuire; Cray

Research, John Rollwagen; and Cardiac Pacemakers/St. Jude Medical,

Manny Villafana. This was followed

by audience comments.

- The July ‘Our Stories’ provides Lowell's remarks and background information.

- VIP Club Volunteer extraordinaire Keith Myhre created a video of the event. RCHS's Robyn Priestley converted the video into a youtube image for the public to view, https://youtu.be/DvC3API_64I.

Thanks to the planning committee for making this event happen; Chad Roberts, Dave Beal, Jay Pfaender, Don Hall, and Lowell Benson.

- https://vipclubmn.org/Locations.html#Commemorated shows the initial plaque installed at this location.

- https://vipclubmn.org/Articles/40-Yr%20Plaque.pdf chronicaled our 'electronic' search for the plaque.

1.0 Table of Spin Off Corporations

None of the organizations listed hereunder are 'medical device' companies. Medical device companies flourished in Minnesota starting with Earl Bakken's formation of Medtronics in the late 40s. Don Hall's book talks about some of them. The stimulus of Bakken's device work was at the University of Minnesota medical school.

ERA -> Unisys Spinoff Organizations |

YEAR |

CDC spin off's |

| Ramsey Engineering | 1953 | n/a |

| General Kinetics | 1955 | n/a |

| Northport Engineering {Editor's note: See Bill Klingner article below this table.} | 1956 | n/a |

| Midwest Circuits Inc. (later became Fabri-tek), Transistor Electronics Corp, and Control Data Corporation | 1957 |

|

| Data Display (later acquired by CDC) |

1958 |

|

| General Magnetics Inc. | 1959 | Flame Industries |

| National Connector Corporation (with people from Magnetic Controls), Flortronics Inc, Nuclear Data, Whitehall Electronics (later acquired by Electro-Science Investors), Electro-Med Inc. (also acquired by Elector-Science Investors), | 1960 | |

| Data Management Inc., Theradyne Corporation, Minneapolis Scientific Controls Corporation | 1961 | |

| Aries Corporation, Tronchemics Research Inc. | 1962 | |

| Mohawk Data Sciences Corporation by Lauren King, and Ted Robinson, former Univac employees. | 1964 | |

| Wiesmantel and Associates | 1965 | |

| Analysts International - grew out of Aries Corporation (see 1962). | 1966 | Computer Systems Inc. Computer Communications |

| 1967 | Data Action (NCS) | |

| Atron (acquired by Mohawk Data Services), Comcet (became NCR-Comten), Comserv | 1968 | Astrocom, Data 100 (became Northern Telecom in 1979), |

| United Software, Dicomed | 1969 | The Analyst, Data Central, Techanalysis, Data Card |

| Community Electronics, | 1970 | |

| Turtle Mountain Corporation in Dunseith, ND spun off from Atron (a 1968 spin-off), TMCfromNDSU.pdf (vipclubmn.org) | 1971 | Midwest Data Systems |

| 1972 |

Datagraph, Cray Research,

|

|

| 1973 | ||

| 1974 | Network Systems | |

| 1976 | Williams Sound Corporation | |

| 1983 | ETA, Edge Computer | |

| Printware, Inc. {Editor's note: See People, M-N for Don Mager's mini-bio, and article below Northport article.} | 1985 | |

| TeamQuest was founded by three employees from UNISYS http://vipclubmn.org/USsites.html#ClearLake; InfoPet | 1991 | |

| Product Development Association, Eagan Minnesota | 1994 | |

|

|

2.0 Northport Engineering by Bill Klingner

Your

request for information on the history of Northport Engineering's development

is thought provoking. I'll start with a little about my partner John

Webster and me. We graduated from the University of Minnesota with Electrical

Engineering degrees, John in June of '50 and I in Dec. of '50.

Your

request for information on the history of Northport Engineering's development

is thought provoking. I'll start with a little about my partner John

Webster and me. We graduated from the University of Minnesota with Electrical

Engineering degrees, John in June of '50 and I in Dec. of '50.

John's first job was in the hearing aid industry while mine was with U.S. Steel in Youngstown, Ohio. Together we formed Northport Engineering as a manufacturers agent company to support the electronic component and manufacturing industries in 1956 and 1957.

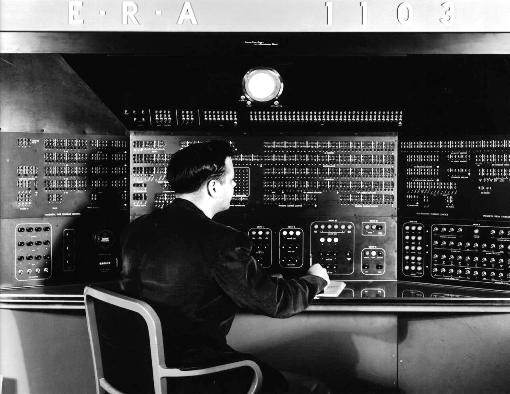

{Editor's note: By this time, Bill Klingner was working at Remington Rand Univac - shown on the right as he worked with the 1103 computer.}

Our business followed the growth of the computer industry and we selected lines and manufacturers to support the industry. Manufacturers sought us out to represent them in areas such as memory cores, resistors, capacitors, and associate products. Our customers included Litton, CDC, UNIVAC, St. Jude, 3M, Honeywell, UNISYS and Medtronics.

John passed away in the 60's. My son, Cary, began working with me in the 70's while in high school. He took over as President in the 80's as I phased into retirement. Cary became owner in the late 80's.

A number of engineers joined us such as

Robert Schneiderhan and we ended up with a staff of 10 to 11 people.

The company continues to serve the electronic industry under Cary's

guidance and has been in existence now for 50+ years. Bill Klingner.

![]()

3.0 Printware by Don Mager

Printware, Inc. was founded on May 16, 1985, to develop

and manufacture high resolution laser printers, computer direct to plate

machines, and associated consumables. This was the result of two serendipitous

events: I had come across a unique laser imaging technology 3M had developed

and was willing to license, and I had completed 30 years at Sperry and

was therefore ready to move on. So it was that Dr. Al Taylor, a 3M employee,

and I founded Printware. I provided most of the "seed" money and was

the CEO. Al continued to work at 3M and was never a Printware employee. The first two employees I recruited

from Sperry were Tom Petschauer and Rick Pliml. Our first workplace was an apartment in an

apartment building which I owned. We faced

two immediate, major challenges as we started-out: obtaining adequate

financing and developing the planned high-tech printing products.

At Sperry, writing proposals was a regular part of the job, and this

experience was tremendously helpful in writing a cogent business plan

for Printware. Amazingly, perhaps because we were digerati – or

in spite of? - we were able, over the next few years, to raise $13M

without using any venture capitalists or financial institutions.

The license agreement with 3M gave us access to several of their patents

related to laser imaging and related consumables. The key patent pertained

to a unique laser beam scanning method which utilized a resonant galvanometer

versus the conventional multifaceted rotating mirror. 3M had developed

this technology at a cost of $8M, but it did not fit into their long-range

business plans, and so they licensed it to us on a royalty basis with

no up-front fees. In fact, 3M eventually invested a substantial amount

in Printware!

Although the 3M technology was designed for 300 DPI

(dots per inch) applications, we realized that market would be dominated

by Japanese companies, and therefore we went for the high-resolution

market. Unfortunately, the 3M technology was developed only to a point

where it was barely adequate for 300 DPI. Achieving quality high-resolution

capability turned-out to be a much greater challenge than we had anticipated.

A factor that made the imaging product development especially interesting

and challenging was the many diverse technical disciplines involved,

including logic design, circuit design, mechanical design (involving

packaging, precision transport mechanisms, galvanometers), complex laser

imaging optics, chemistry (toners, infrared sensitive plate material,

drum coatings) and raster image processor software (not to be confused

with word processing software). Fortunately the Printware engineers,

most of whom came from Sperry, were very talented. Those from Sperry

included Dave Shelander, Jim Howe, Mike Kelleher, Paul Richardson, and

Rod Cerar.

Our first product was a laser printer, the 720IQ, with

1200 DPI horizontal X 600 DPI vertical resolution, which is equivalent

to 720 DPI. At the same time we introduced the 600HD raster image processor

(RIP) which had industry-typical graphics, fonts and formatting capability.

![]()

The next product, the 1440 Platesetter System was truly unique and revolutionary. It provided direct computer-to-plate capability at 1200 x 1200 DPI resolution. This technology simplified the plate-making process with up to 80% savings

in consumables. The Graphics Arts Technical Foundation (GATF) granted

Printware the Intertech Technology Award for 1990 on behalf of the 1440

Platesetter. Previous winners included companies such as 3M, Dupont,

and Eastman Kodak. This award recognizes technologies which are expected

to have a major future impact on the Graphics Arts industry. Along with

the 1440 Platesetter, Printware introduced the 1200 HD RIP which was

capable of emulating Adobe’s Postscript page description language.

Printware was the first company to achieve this feat, which many

industry experts said was virtually impossible because of the Postscript

complexity. We called our emulator “Printscript” which was

very close to Adobe’s Postscript. Adobe did not appreciate that

and after considerable legal wrangling with Adobe’s attorneys

we finally agreed to change the name to “Printstyle” in

exchange for certain legal rights concerning Postscript. The primary

reason they were so tenacious in going after us was because of their

concern that others would follow in our footsteps and emulate their

language, causing them to lose royalties – which is exactly what

did happen within a few years.

These high resolution products required

the development of special high performance galvanometers with capabilities

far beyond anything available in the marketplace. In fact the requirements

were so stringent the final design required, among other things, that

the resonant galvanometer be in a vacuum and exotic materials be used

for the resonating torsion bar. This design effort was led by Dave Shelander

and resulted in one of several patents Printware was granted.

The

first major customer for the 1440 Platesetter was Deluxe Check which

had more than 50% of the check printing business in the U.S. Although

profit from selling the plate setters was marginal, the strategy was

for the consumables to be the big profit. Unfortunately for Printware

and unbeknown to Printware, Deluxe Check shipped one of the very first

1440 plate setters to Japan for the purpose of developing a competitive

consumables source. It became increasingly difficult for Printware’s

domestic supplier to compete with the Japanese source. It was a terrible

blow to Printware’s long term strategy and profitability, but

we were by no means enervated.

By 1991 Printware had 120 employees

and was profitable, with annual revenues of over $14M. In 1996, Printware

had an initial public offering, and the stock began trading on the NASDQ

exchange under the symbol PRTW. In 2000, Printware was taken private

and the company now (2008) flourishes under the leadership of Tim Murphy,

the President. I first met Tim when, as a high school attendee, he worked

part-time in one of my dry-cleaning plants. After receiving a computer

science degree and a two-year stint with the Peace Corps, he joined

Printware. The majority of Printware’s business at this time is

consumables-oriented.

One of the management lessons we learned at

Printware was that getting too far ahead, technologically, of the rest

of an industry such as printing and publishing presents some challenging

marketing problems. All the established suppliers feel threatened and

so, like a pioneer, you wind-up with all the arrows [canards] in your

back as the establishment scrambles to get up-to-speed on your technology

without having to pay huge R&D costs.

Almost always, especially

in start-up companies, marketing – not technology - is the nettlesome

challenge. It doesn’t seem fair! [dvm]

In this Chapter

Commemorative Plaque

Corporations table

Northport Engineering

Printware, Inc.

Chapter 6 edited

7/8/2025.