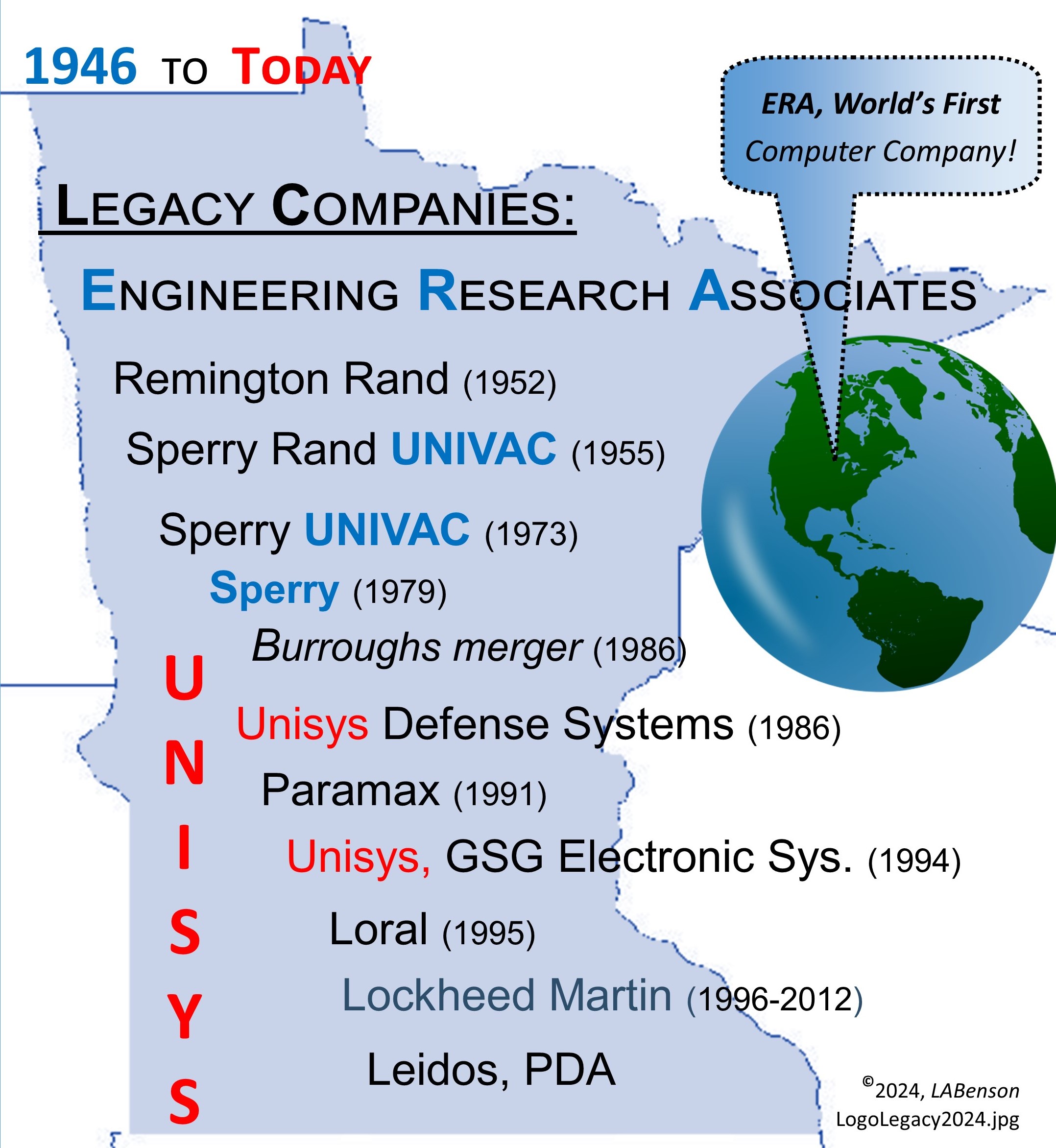

Information Technology (IT) Pioneers

Retirees and former employees of Unisys, Lockheed Martin, and their heritage companies

Government Systems, Chapter 63

1. Introduction

Why a Government Systems chapter when Air Traffic Control for the FAA, NTDS for the Navy, the MTDS for Marines, the Missle launching [Aerospace] for NASA, and the Airborne chapters were/are systems for the government?

Because the company did more than 'dabble' in several areas as they applied technologies and skills of their innovative staff. Even in ERA days the engineers and management sprang on opportunities to try to make money for their stockholders, i.e. during ERA days there were developments of airport Ground Support Equipment and the bore hole camera.

2.0 NEXRAD

2.1 From Gerry Pickering:

Though most people don't realize it, they watch NEXRAD in action every day on the evening weather report.

In the 1980s I had the privilege to manage software development of NEXRAD, the Next generation weather Radar. Sperry System Management in Great Neck, NY was prime, Univac Technical Services Division in Trevose, PA was software subcontractor. NEXRAD tracks and forecasts violent weather such as tornados and is still in use and feeding the weather services and local weather channel something. Andy Lang was the Technical Manager of the NEXRAD software. Irv Baum was the Program Manager and had the closest day to day interface with Great Neck and the customer. Andy and Irv sat side by side, and from my standpoint as their boss, worked as a single unit. I worked in Trevose where the software was developed. I had about 50 or so programmers assigned to the project. The overall NEXRAD management, including design of the radars and site selection and preparation were done elsewhere. Sperry System Management was the remnants of Sperry Gyro left in Great Neck, NY. Management meetings were held regularly, some in Great Neck to which we would journey, some in Trevose to which the management team from Great Neck would journey. The project was awarded in the early 1980s before Burroughs bought Sperry, and continued after the merger. The Sperry marketing types that won the business for Sperry were heralded within the company. The award was before I transferred from Blue Bell to Trevose. [Gerry Pickering]

2.2 From Andy Lang:

I started work with Sperry Univac (that was the name at the time) in 1966 working on a sub-contract for Bell Telephone Laboratories (BTL). Located in Whippany, NJ. BTL was prime contractor for the NIKE-X Safeguard Anti-Ballistic-Missile (ABM) system. Bell selected a specially designed Univac ‘super computer’ for the ABM system. This ‘NIKE-X’ computer was [I believe] a militarized, water cooled, derivative of the Univac commercial 1108 computer system. It was a monstrous super computer. {Editor’s note: The NIKE-X computer(s) pre-dated the 1108 – see page 5 of Articles/SperryMilitaryComputersbyGG.pdf. The 1108 multi-processor designs used architecture derivatives from the NIKE CLC.}

Here is a little background about NEXRAD. The NEXRAD procurement was initiated under the joint sponsorship of three government agencies:

- The National Weather Service,

- The Air Weather Service [Air Force] and

- The Naval Oceanographic Command [I think].

The procurement was a three phase competitive procurement with each phase being independently funded. Phase 1 started in ~1980 and was awarded to three competitors, 1) Sperry, 2) Ford/Westinghouse and 3) Raytheon. Phase 1 was a one year contract, titled “System Definition Phase”. The competitors had one year to define and design a complete NEXRAD system on paper. Sperry System Management, Great Neck was prime and focused their expertise and attention on the ‘Doppler Radar’ element. Sperry System Management went to Sperry ‘Technical Service Division (TSD)’ for support in the data processing element of NEXRAD.

I see there are questions: “why was a UNIVAC computer not selected?”

There were a number of reasons. The data processing element of NEXRAD

called for a real-time distributed processing super-mini class computer

system family. The data processing system had to have real-time operating

system software and provide a real-time software development environment

to interface with the operating system. To be “cost-competitive”

it was important that the selected Data Processing family of computers

include more powerful [more expensive] elements and less powerful [less

expensive] elements which could be selected in accordance with the varied

processing needs of the NEXRAD system. The NEXRAD procurement also had “choice

of software development language” restrictions. Bottom line:

You had one year to define and design a complete NEXRAD System,

You did not have the time luxury of designing and developing a new data processing computer system environment, you had to find something “off-the-shelf” operationally ready to commence NEXRAD software development. Sperry Univac products were looked at very carefully but just did not measure up to existing competitor products which did fit the NEXRAD needs. DEC (Digital Equipment Corporation) products were considered as were others. The ultimate choice was Perkin-Elmer [later named Concurrent Computer Corporation] and that was the Data Processing Computer system choice for Sperry’s NEXRAD Project.

Though some may strongly disagree that there was any computer selection

influence at all, it is pointed out that the National Weather Service

in Norman Oklahoma had been previously using Perkin-Elmer computer equipment

for their initial Doppler radar feasibility studies.

Just to finish the story, as per the procurement plan, two competitors

from Phase 1 were awarded funded contracts to proceed onto Phase 2.

Sperry and Raytheon were the winners. Phase 2 was also a one year contract

referred to as: “Prototype Development Phase”. You had one

year to build the system you designed during Phase 1 and make it work.

The winner of Phase 2 would then be awarded the Phase 3 production contract

for the manufacture and deployment of NEXRAD Doppler Radar Systems across

the US. Yes, Sperry [later named UNISYS] was the winner.

2.3 From Les Nelson: There’s more to NEXRAD than meets the eye

original printed source unknown,

"It was nearing 10 p.m. EDT on Sunday, Aug. 23, when the National Weather Service’s WSR‑88D radar, located in Melbourne, Fla., observed a tropical cyclone gathering force in the Atlantic Ocean. As Hurricane Andrew revved up for its fierce attack on southern Florida, it was the first hurricane to be observed by a National Weather Service (NWS) WSR-88D in an operational setting. All through the night the WSR-88D, also known as the Next-Generation Weather Radar (NEXRAD), tracked the hurricane and enabled weather forecasters to accurately project the storm’s path and authorities to issue evacuation orders to threatened areas.

The WSR-88D, built by PARAMAX Systems Corporation, is the newest NWS radar system. This advanced Doppler radar system determines in real-time not only the size and intensity of a storm but also wind speed and direction. As a result, weather forecasters can now obtain high-resolution data on hurricanes, tornadoes, flash floods and other storms within minutes.

To achieve this, NEXRAD uses a specialized high-performance computer—an advanced programmable signal processor originally developed by Unisys for use in military systems—to extract reflectivity and Doppler velocity data [called “base data”] from raw radar returns. From the signal processor, the base data moves in digital form along high-speed data communication lines to a radar Product Generation Computer which uses sophisticated meteorological algorithms to generate user products. These products, which include both tabular and graphical information, are then transmitted to user positions and workstations for display and analysis. Among the most important products are easy-to-read graphical presentations of Doppler data which use a technique called false-color imagery to show observed wind speeds and directions. False-color imagery assigns different hues to the various wind speeds within an air mass. Cool colors, like blue and green, are normally used to indicate air movement toward the radar; warm reds and oranges show air movement away. The Radar Product Generation computer also processes the radar data to develop an overall picture of storm dynamics and severe weather potential. Automatic alarms call attention to predicted danger areas and display the system’s assessment of a storm’s potential severity. The result is a color-graphic profile of the weather mass, along with its predicted behavior.

NEXRAD systems have proved themselves repeatedly over the past several years, but never more decidedly than during Hurricane Andrew’s August rampage through southern Florida. According to Bart Hagemeyer, meteorologist-in-charge at Melbourne, portions of Hurricane Andrew were observed on the Melbourne WSR-88D for more than 24 consecutive hours Aug. 23-24. “We were surprised at how much detail about Andrew’s structure was evident even at long range in reflectivity data, he said.

The NEXRAD program was begun in 1979 when the U.S. Departments of Transportation, Defense and Commerce joined forces to produce advanced weather radar units that would provide a national warning network to aid the NWS, an agency of the National Oceanic and Atmospheric Administration. Initially, three companies—Unisys [then Sperry], Raytheon and Ford Aerospace—were selected to perform systems definition studies in preparation for the design and production of NEXRAD systems. Unisys and Raytheon were subsequently selected to compete in a validation phase. Unisys and, specifically, Electronic Systems, used its expertise in high-speed computing and real-time software and its high-reliability manufacturing capabilities to provide a cost-effective, technically superior solution.

In the 13 years in which Paramax has been involved with the NEXRAD program, teamwork and strategic alliances across the divisions have paid off. Systems Development in Great Neck, NY, serves as the prime contractor and is responsible for the design and delivery of a totally functional, integrated system. Electronic Systems provides signal-processing hardware and software. Information Systems at Ivyland, PA provides and supports all other NEXRAD software. The NEXRAD hardware supplied by Electronic Systems includes Programmable Signal Processors (PSPs), Hardwired Signal Processors (HSPs) and other Radar Data Acquisition (RDA) electronic modules. Clearwater Operations is responsible for manufacturing and testing these units, with Printed Circuit Board Fabrication performed at Shepard Road Operations. Electronic Systems Hardware and Software Engineering organizations continue to provide training and support, especially as it relates to the Signal Processing Program and diagnostic software which executes in the PSP. Electronic Systems Hardware Engineering is also currently performing a technical oversight function, interfacing with Motorola Corporation which is developing new communication modules for NEXRAD systems.

“The Electronic Systems technical expertise in software, firmware and production hardware, coupled with a strong comprehensive quality program, has made Electronic Systems one of the best NEXRAD subcontractors,” said John Fox, director, Program Management, NEXRAD Operations. “The entire Electronic Systems team continues to do an outstanding job in the production of signal processors and radar data acquisition modules.”

Electronic Systems’ involvement in the program began in 1982 with an investigation into the feasibility of using a programmable signal processor in the NEXRAD system. Electronic Systems first came under contract in May 1983, and less than a year later demonstrated a prototype Programmable Signal Processor, with a full complement of operational software running real-time and accurately processing simulated radar signals. “We showed what a small, dedicated and highly skilled team can achieve,” said systems engineer Dr. Ray Artz, who shared project engineering responsibilities with hardware engineer Rick Martin [now director of Hardware Engineering] during most of the NEXRAD development. “Our three hardware engineers; Vince Splett, Tom Erickson, and Tim Lee architected the processor then developed and demonstrated 11 new board types in less than nine months! Our software engineers Les Nelson and Bob Ellingrod were ahead of their time in using advanced information-hiding techniques to improve software reliability and in developing and using a complete PSP register-level simulation to check out all code prior to the brief four weeks available for software integration. And of course, the support we received from Prototype Manufacturing was outstanding.” By the fall of 1986, the first prototype NEXRAD radar was completed in Bloomfield, CT - the major “test site” for NEXRAD systems. Electronic Systems provided valuable integration support. In mid-1987, with less than two weeks remaining on the NEXRAD Validation Phase contract, Electronic Systems was asked to lead a Tiger Team to demonstrate improved Doppler processing capabilities. The team worked around the clock, demonstrated significantly enhanced system performance and solved in days, problems which had been plaguing the prototype NEXRAD system for months. This effort has been cited as critical for the subsequent Unisys production award. Based on its demonstrated performance, Electronic Systems work scope was increased to include productizing and manufacturing the HSP and building additional RDA modules.

To date, 10 systems have been installed, with more than 150 Doppler radars set for installation in the United States and at overseas military bases.

Serving and protecting the public are among the goals of those agencies that deploy NEXRAD. Dr. Elbert W. “Joe” Friday, Jr., director of the National Weather Service, said, “The news of NEXRAD is not only upbeat, but it represents the most significant improvement to weather forecasting in my 31-year career. And we’re still making positive improvements. Every time we look at storms with this system, we see more information.”

“The radar has achieved significant successes

that prove the value of this new forecasting tool in saving lives, property

and money,” said Dale C. Hutchinson, vice president of NEXRAD

systems, Systems Development division. “We look forward to installing

the rest of the systems over the next four years as we go into full-scale

production.” A NEXRAD system will be installed in Eden Prairie,

Minn., in the third quarter of 1994.![]()

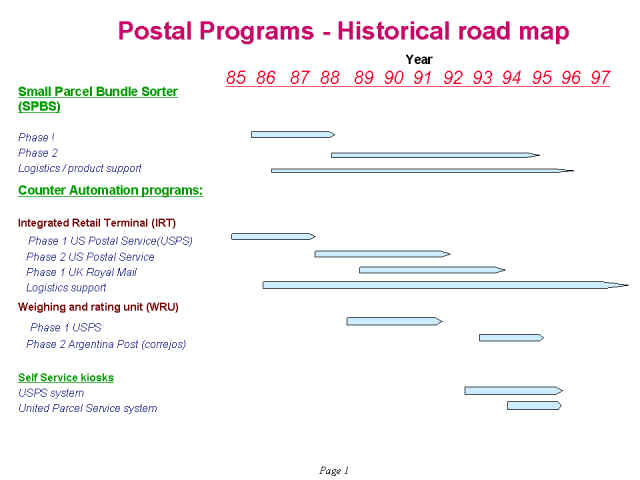

3.0 Postal

We

started working on automation of Postal Systems in the late 80s. Dan

Holste was the original engineering manager assigned to developing the

hardware. This general road map is provided by Anil Deodhar. These

technologies and systems have been transferred from St. Paul to New

York. [lab]

4.0 Agriculture

Agriculture systems began in the eighties and nineties as the LEGACY companies investigated applying technologies to new business arenas as a defense conversion initiative. We did do some GPS farm tractor locating and guidance systems work to aid in accurate spreading of liquid fertilizers.

5.0 Intelligent Vehicle Highway Systems (IVHS)

In the early 90's, Lowell Benson [engineering] and Dean Nelson [marketing] were asked to investigate the US Department of Transportation's Intelligent Vehicle Highway Systems (IVHS) business area. We found that the Sperry, Great Neck Division had been in the traffic signal control business but had phased out of it. We did a market analysis, created a MNDOT Traffic Control Center to 'cell phone' congestion information system then demonstrated it at a national conference in Florida. Our analysis was that it would be 5 years before we'd be profitable after a $500k development investment. Management declined the investment opportunity thus the concepts were dropped. [Now, 20+ years later, these systems are common place - we could have been on the forefront of these Department Of Transportation systems.

This investigation got me contacts at the Minnesota Department of Transportation and the U of MN's Center for Transportation Studies (CTS). Those contacts resulted in a job at CTS when UNISYS laid me off in the spring of 1994. By LABenson

In this Chapter

- Introduction

- NEXRAD

- Postal

- Agricultural

- Intelligent Vehicle Highway Systems

Chapter 63 edited 7/13/2025.