Information Technology (IT) Pioneers

Retirees and former employees of Unisys, Lockheed Martin, and their heritage companies

16-bit Computers, Chapter 54

1. Introduction

The 16 bit computers became replacements for many of the earlier

18 bit computer systems. The Instruction Set Architecture (ISA) has

five instruction formats, mapped onto 16 or 32 bit word lengths. The

1616 had 120 instructions working with 8, 16, or 32 bit operand word

lengths. The initial memory used had a 300 nanosecond access time with

a 750 nanosecond cycle time. The AN/UYK-20 had 167 operations, having

added some 64 bit word length functions.

Of special significance is that embedded card sets from this

architecture went into the AN/UYQ-69 display subsystem setting an embedded

processor trend for the later AN/UYQ-70 system, JDAMS, etc. [lab]

Note that the RMF 400 in the genealogy chart below is a 16-bit AF machine,

thus is included in chapter 57.

1.1 User Feedback

From Mark Greenia: Watch a 1975 Computer History video: Sperry Univac AN/UYK-20 at the Clearwater, FL factory, https://www.youtube.com/watch?v=i2Et8oIo-f8. Thanks to CHAP's Mark Greenia and data from the Hagley Museum.

2. Computer Family

The 16 bit models are: type 1616, AN/UYK-15, MPC16, type 3760, AN/UYK-20, AN/UYK-23 [type 1816], LAMPS, RMF500*, RMF 200, AN/UYK-502, AN/AYK-14 2nd Source, AN/UYK-505, AN/UYK-44, and the AN/UYK-507.

*The Reconfigurable Module Family (RMF) used 500, 400, etc. to indicate the KIP speed of the machine, i.e. thousands of instructions per second. The Instruction Set Architecture breadth of these designs is quite apparent on a representative 'Repertoire Card'.

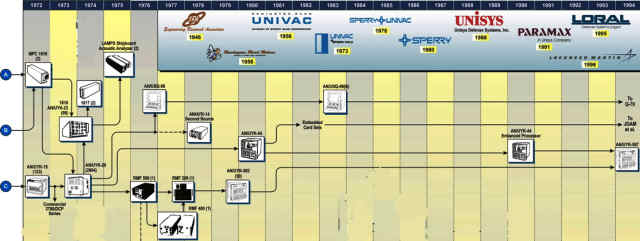

3. Genealogy Chart

The string of our 16 bit, common ISA are illustrated by this chart which was extracted from the overall genealogy chart. Glen Kregness was the general architect of this Instruction Set Architecture which had sixteen 16 bit registers for each of the four operating states. For example, the interrupt state had its own set so that the operating set of registers didn't have to be saved when the normal operating sequence was interrupted. [lab]

4. Unit Descriptions

4.1 1616

4.1.1 From Lowell

The Unisys type number 1616 that began this ISA was available and appropriate for a 'desktop' computer that had sixteen 16-bit registers. It was also designed to support sixteen 16-bit Input/Output channels. A very early unit was put aboard a submarine for experimental signal processing. A forward hatch was left open causing a swell of salt water to cascade onto this unit. Dick Erdrich dried out the unit, re-installed it, and the Navy continued with the processing experiment. Glen Kregness, Dick Erdrich, Bob Beljeski, Dave Albee, et al. were involved in the design of computers with this architecture. The first unit shipped in December 1971. Lowell Benson became supervisor of the 'features' design team when he returned from Germany in August 1972. [lab]

4.1.2 From Dick Erdrich:

The 1616 ushered in the next generation [fourth] by the use of Medium Scale Integration (MSI) Transistor-Transistor Logic (TTL) devices with the majority of the devices coming from the 9200 family produced by Sylvania. The UYK-20 shared this technology and the Memory Processor {see section 4 of 32-bit computers} was probably the last design in this line. When we did the UYK-43 and UYK-44 developments, the next generation [fifth] was defined by the use of Application Specific Integrated Circuits (ASIC) and from that point the major change has been increased density in both ASIC and programmable devices.

I would like to point out that the uniqueness

of the 1616/UYK-15 Serial I/O Controller (SIOC) design that I did was

the ability to configure the operating protocol by software for each

channel [interface] independently and in real time. It was capable of

providing 1.3Mbps of throughput in any format desired. The RS-232 and

MIL-STD-188 capabilities were a relatively small part of the design.

The MIL-STD-188 was used for the COMSEC program being developed by the

Marine Corps at the time and resulted in the requirement for Variable

Character Length Serial (VACALES) being included in the UYK-20 functional

requirements.

The initial SIOC architecture was targeted at NASA for satellite

data de-commutating. At the time all de-commutating was being done by

fixed format devices which meant that at any given receiving station

as each satellite came into view a different piece of hardware was needed

to bring in the data. A lot of this data was being retransmitted to

JPL in Pasadena where the two UNIVAC 490's in the basement were routing

the data from the receiving stations to storage and de-commutating devices.

When the SIOC's were installed there, all of the data coming in could

be de-commutated and stored as finished files.

![]()

4.1.3 From Lyle Franklin:

In the 1970s, the world was going 16 bits. All microprocessor packaging by Intel and TI and others were 16 bits. DSD had been in a sole source position with the 18, 30 and 32 bit computers for shipboard applications. The McNamara total package procurements were beginning to work around the so called standards. The last total package procurement Univac participated in was the Aegis program as designated computer supplier with the UYK-7. NAVORD and NAVELEX were looking for other solutions because the Univac ship hardware required motor generators as well as outmoded interface hardware.

As an assistant to Ruel 'Red' Phillips, George Workman assembled a small team to examine 16 bit applications and designs. At that time the only likely competitor in the field was the Texas Instrument 2540. It had been selected by many prime contractors for the NATO Sea Sparrow program. Marketing had obtained information concerning this machine. Glen Kregness performed the analysis. George, Glen, and Lyle Franklin, met with Red. He reviewed our data and agreed to fund the design of a 16 bit machine. At that meeting it was agreed to use a lower cost 56-pin card developed by an engineering and manufacturing study. It was also agreed to develop hosted software and use a regulated power supply. For the future the unit must be low cost and competitive in performance. Red also agreed to the commercial equivalent, the differences being the commercial grade components and no moisture fungus proofing of the cards. Thus the 1616 was born.

A side bar of the story was that Lyle had acquired a detailed spec of the TI 2540 and sent it to Navy Systems for evaluation. A month later it appeared on my desk with a note stating "another Mickey Mouse machine". I called Glen Kregness and asked if he would review the the specification. Glen was on loan to Plant 4 at the time, but he picked up the specification that Friday on his way home. On Monday morning he was in my office before I [Lyle] arrived. He said that they were way ahead of us architecturally and were doing interesting things with general registers. When we met with Red, Glen said they did some funny things and he could design a more efficient machine. The above ground rules were discussed and Red started the development. The Marketing Department supplemented Red's funding.

Glen Kregness used some of the features of the TI 2540 in his design of the 1616. Leo Bock listened when I insisted the we needed a host computer for software development. Again a feature of the TI box. When Leo and I visited Gilfillan, I had hired Leo after the development of the unit was completed. Leo had been the engineering manager of the 1616. Gilfillan had already selected the TI box. As Glen had promised me our unit was faster and more efficient. I suggested we do a paper benchmark. Also to commit to an early delivery of a prototype box and to meet the TI price excluding spares. We did get the contract. Come time for delivery I got a call from Lee Best who at that time was in manufacturing. Problem was the memory stack might touch the power supply. Lee said the insertion of a Knox Lumber piece of filigree board would solve the problem. I agreed so that's how Knox became a supplier. Upon delivery to Gilfillan, I pressed Bill Laliberte to get a government nomenclature. Previously we had briefed the radar code 6179 [seems to be the code I remember.] As Capt. Swenson had asked me to sell a UYK-7 into the SPS-48 program, which was impossible, I wanted to insure there would not be a stumbling block. I also contacted a friend of mine who was Erick's and Don Ream's boss, Code 6170, and was assured we would get approval for code 6179 purchase. Thus the AN/UYK-15 was born, same printed circuit cards but packaged in a grey box instead of a blue box.

4.1.4 More from Lyle

Been reviewing some of the data again. The 1616 program started out

as a commercial and a military machine. Two sets of components were

purchased, one mil spec and the other comm'l equivalent. We were attempting

to have a computer that comm'l division could also use. The reasoning

was to broaden the marketplace by having comm'l develop other software.

The soaking had nothing to do with the mil version of the 1616. The

sale to Gilfillan was for a mil spec box, MFP and all. Could not have

received UYK-15 nomenclature with a comm'l computer. Due to the NIH

factor comm'l focused instead on defining a communications processor.

That was the other mission of the UYK-15.

NAVSEC, Capt. Swenson, Don Ream et al. had heard about the 1616 and

someone told them it was developed for NASA. As such they wouldn't accept

the machine. The 1616 was developed for the shipboard Navy. For years

Dick Huberty and I worked with NAVORD and the 1219's. We knew ORD was

going system competitive and we had nothing to offer. Believe me, marketing

was involved in the 1616 initiation and development.

Without NAVSEC support, the military acceptance of the 16 bit line would

have been difficult. We focused our marketing effort on NAVORD and NAVELEX.

Bruce Olson and I made several trips to ORD exposing them to the UYK-15

design aspects. At the same time, NELC was getting ready to announce

a system called GUARD. The shipboard teletypes printed everything on

the teletype net and seaman would manually sort the messages for their

ship. The Guard system was hardwired with plug board so only the messages

addressed to the ship would be printed. Initially I worked with Bob

Sigfried, Ray Smith and a helper in NAVSEC. We came up with a system

termed PACE, Program Alterable Communications Equipment. Ray discovered

a code in NAVELEX that was designated to solve the communications problem.

Ray, Walt Massengale and John Rooney took over the effort and John developed

what later would be called NAVMACS. This also was why I was pushing

Capt. Hager for the RS-232 interface on the UYK-20.

4.1.5 From Bobby Brewer

Lowell: I was in Univac Commercial/Southern Operations from 1970 through 1986, Atlanta Development center under Ron Q. Smith for about a year, and Dave Holt at the layoff. I had worked on a project in about 1976 with Defense Systems Division on acquiring 1616/UYK 15's for a commercial customer (NDC). I think that I might have worked with you (Lowell) on that project. We sold NDC about 40 1616 MP systems and ended up writing all the code to operated them in a high volume TP environment:

TP/OS including device drivers for MSA 30 bit interface including Univac 8424's and U36 devices, Maintenance programs ported to 494 ASM, In other words "everything a high performance TP environment needed".

Then we sold them without a maintenance contract and installed one system! NDC changed VP's about that time and asked for a maintenance contract. Commercial Operations quoted them $1,000,000.00 and that basically killed the whole project. I think they kept the 1616's until they had depreciated them and then scrapped them. That was my most depressing point in my career at Univac. Regards, Bobby Brewer 8/27/2015

Bobby: It is entirely possible that we met in the mid 70s when I was a supervisor of mini-computer support in the hardware engineering department. Sorry that I don't remember you, I vaguely recall that St. Paul had done a proposal for 40 1616 systems for an organization in Atlanta. For that system we had to design a Satellite Serial Input/Output Control (SSIOC) drawer to expand the 1616's RS-232 channel capacity. Prototype manufacturing built two units for the first delivery, then project activity was suspended and cancelled by the customer for a reason unknown to me at that time.

You have provided the answer - a change of the customer's VP and a $1M support quote! Thanks for your experience snapshot (it is indeed a small world!) Regards, Lowell

4.2 AN/UYK-15

First delivery December 31, 1971. The salt water dunking of the 1616

triggered a military rugged unit, also with hardwired circuitry. A cabinet

model and a rack mounted model were designed and built. These developments

also incorporated serial interfaces in lieu of the parallel interfaces

in four channel groups. These were the commercial RS-232 and Mil-Std-188.

We built and delivered over half-a-dozen 19" rack mounted units into

an Army 'Counter Mortar' system. [lab]

![]()

4.3 3760/DCP-40/Inter-Computer Control Unit (ICU)

These two machines aren't shown on the genealogy chart BUT deserve

mention herein:

By Rapp ==> Dewaine Osman, former DSD VP of Marketing, and a close

friend of mine, was sent to Salt Lake City as VP-GM of C&T. He commissioned

Red Phillips, Bob Oulicky, et al', to develop the

3760 as a front end interface to IBM 360 computers. This allowed C&T

terminals to interface with the very large IBM installed base at

that time. The 3760 was indeed based on the 1616 computer which was

the predecessor of the UYK-20. I served as C&T National Sales

Director from 1973 to 1974 and was in charge of winning McAuto. The

3760 was a part of the McAuto equipment suite which included our

terminals and displays. Reference pages 3 and 4 of

History of

Networking (vipclubmn.org). The 3760 was not a commercial success due to

lack of support from Univac commercial in Blue Bell. C&T was

disbanded as a division in 1974 and Osman moved to the Federal

Systems Division in Washington, DC and I moved to St. Paul to become

GM of TSD. Mr. Probst sent

Don Edam and Dan Brophy to Salt Lake to run McAuto but Joe

Kroger wanted to kill this very major advanced computer services system.

The entire project was terminated by Probst in 1975. Now you know the

rest of the story, as the saying goes!

By Lowell ==> An innovation of this machine was incorporation of

the IBM peripherals interface, an 8 bit wide daisy chain port with terminators.

Bob Jablonski and Howard Morrel were two of the engineers working on

this interface, Bob Oulicky was the department manager.

Lew Carlson was one of the design engineers helping with the

UYK-20 micro-processor based development in St. Paul. Several years

later, he transferred from the Roseville plant to Salt Lake City where

he led the design of the micro-coded Digital Communications Processor

(DCP) replacement of the 3760. John Nemanich's networking

article also discusses

the 3760 and Salt Lake City communications developments. [lab]

ICU (Inter Computer Control): Also not on the genealogy chart, in the mid 70s as the US Navy was doing initial testing of the AN/UYK-20, a Navy Admiral told a German Admiral that they could have a copy of the AN/UYK-20 however Foreign Military Sales of a a new technology micro-programmed computer would be several years in coming. After discussions a definition of an ICU came about. The ICU was to interface between an IBM computer in the Wilhelmshaven laboratory and the 642B and 1830B computers already in their laboratory. We repackaged a 3760 into a commercial rack to make the first connection via the 3760s IBM byte/serial daisy-chain interface. Then we repainted S/N 32 AN/UYK-20 a German Navy blue, gave it an ICU nameplate, and put it on a shelf in the rack with the 3760. We did a 16 bit inter-computer connection between the 3760 and the now blue mini-computer. Then we did a double channel (32 bits) inter-computer connection to the 30 bit 1830B. The 1830B already had an inter-computer connection to the 642B. We shipped the ICU units to Salt Lake City to verify the IBM interface before sending to Germany for installation. Lowell Benson was the project engineer, Bob Oulicky the department manager, I don't remember the marketing personnel. Sperry made money, the German Navy had their new computer type, and a couple of admirals smiled at the cooperation.

The Sperry type number catalogue GS3577 identifies 3760 as a system number, the type number was T8579 with several variations when used with the Series 60, 70, 80, and 90 systems, see pages 772 through 78. .

4.4 MPC-16

An Internal Research and Development project created the MPC16, the

same 16-bit ISA implemented with a Micro-Programmable Controller (MPC)

instead of hardwired logic. This was packaged into a 1/2 ATR chassis.

Career summaries submitted by several engineers mention participation

in this development. Although a few individuals claim credit for the

creation - this, as were all developments was the result of teamwork

by many specialists! [lab]

![]()

4.5 AN/UYK-20

First delivery December 14, 1973

By Lyle Franklin: The UYK-20 was the result of Sperry Univac Defense

Systems Division winning the competitive procurement for the Standard

Navy Mini Computer. CDR Charles [Chuck] Hager, Naval Ordinance Systems

Command, was the officer in charge. He assembled a group to develop

the specification which his office controlled. CDR Hager was a computer

expert. At one point in his career he had rewritten significant portions

of the NTDS program used on one of his duty ships. Prior to the release

of the Request for Proposal (RFP), he had briefed industry on the requirements.

To prepare for the release of the RFP, Richard Seaberg, VP Marketing,

appointed me [Lyle] as the executive of interest. Our team consisted

of George Workman for Engineering, Jerry Meyers for Program Management,

Dave Kolling for Navy Systems, and Gordon Frederick for Navy Marketing.

Due to our varied experiences, conflict concerning the technical direction

occurred. Historically, NAVORD considered that the fire control problems

required 18 bits. NAVSEC desired UYK-7 compatability. As an impasse

was reached, I requested that Mr. Seaberg act as executive of interest

with me as the Navy Marketing representative. Thus, the decision was

made to capitalize on our AN/UYK-15 experience.

When the RFP for a standard Navy mini-computer was released,

many features of the UYK-15 had been incorporated and also included

the requirement for delivery of two units 30 days after contract award.

This required investment to meet that requirement. DSD made that investment.

The pricing evaluation was based on unit price on three individual yearly

pricing tables, key was the projection of the total unit marketplace.

Some believed the total quantity required would be ~300 units. Richard

Gehring, General Manager, supported the Navy Marketing projection of

two to three thousand units. This was critical as CDR Hager was conducting

this procurement as a two step. Two Step procurement allow those that

are deemed to meeting the requirements of the RFP can submit a price

at best and final. Low bidder wins, John Vold provided the pricing strategy.

Defense Systems Division was declared the winner over CDC and General

Electric.

Upon contract award, Donald Schwanz was appointed Program Manager.

Marketing, Program Management, and Engineering worked closely to expand

the I/O capability. Marketing had identified the major user to be Naval

Electronics System Command, NAVELEX. The RS-232 (MIL-STD-188) interface

was critical for their use. Contract terms were that the Navy, Hager,

had total control over the UYK-20 and had purchased DSD’s total

production of the unit. After many meetings and much dialog the then

Capt. Hager agreed to the inclusion.

As most of the peripheral devices such as the 1532 keyboard/printer

and 1540 magnetic tape units were quite expensive, DSD under Bob Seigfried

searched for commercial devices to provide a low cost solution to increase

marketability. These were termed Interim Peripheral Equipment Group,

IPEG, and were assembled by Bob Potter and later John Fritz.

[Lyle]

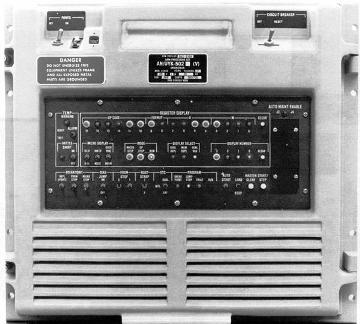

The MPC control logic was packaged into the shipboard AN/UYK-20 for small scale Navy applications, updating systems that had used the 1218 or 1219 computers. The genealogy chart indicates that there were 2,804 UYK-20's built. Actually, there were 2,804 plus one! {Editor's note: see the ICCU on this page.] The unit shown on the left measured 19"x24"x20", weighed almost 200 lbs., and consumed about 800 watts. The basic printed circuit module measured 4" x 4.2", had a 56 pin connector, dual-in-line package small scale integrated circuits, and a dozen test points at the card's top. Sixteen of these cards made up the CPU section. [lab]

UPDATE - In September 2023: The Computer History Archives project posted https://www.youtube.com/watch?v=i2Et8oIo-f8. This is a 1975 story about the Clearwater manufacturing facility using info from the Hagley museum archives.

1975 tidbit: Captain Erick Svendsen had 'promised' German Navy Kapitan, 'Willie' Kraus,

a new small scale computer for their Wilhelmshaven computer development

center. The Germans had an IBM computer in their development center,

in addition to the two CP-642Bs and one 1830B computer. The Germans

did some innovative contracting to buy an Inter-computer control unit

system for system integration demonstrations between the IBM and UNIVAC

computers. St. Paul Engineering put together the demonstration system

consisting of a re-packaged 3760 communications processor from Salt

Lake City and a 'UYK-20' from the Clearwater FL assembly line. This

'UYK-20', was painted a German Navy Blue, had the name plate changed

to Inter Computer Control Unit S/N 1, then shipped with the demo system

to Wilhelmshaven. The U.S. Navy's subsequently received their S/N 32

UYK-20 between their S/N 130 and 131. This method worked because the

3760 unit from Salt Lake City had an IBM daisy-chained byte interface

as well as a 16 bit parallel inter-computer interface. Lowell Benson

was the project engineer putting the system together with help by engineers

Dick Erdrich, Bob Jablonski, and Howard Morrel. Bob Oulicky was the

department manager at the time. [lab]

![]()

4.6 AN/UYK-23 (Type 1816)

4.6 AN/UYK-23 (Type 1816)

First delivery 8/31/1973.

The printed circuit cards from the AN/UYK 20 were modified for conduction instead of convection cooling then designed into a full ATR chassis for an airborne application. This unit had 157 instructions and eight parallel Mil-Std-1397 Type C I/O channels. The full ATR chassis weighed 56 lbs and consumed 500 watts. Dean Free and Bob Beljeski helped me conduct the Mil-E-5400 qualification testing of this model.

The first airborne installation went aboard the Grumman OV-1 plane in the Quick Look II system created by E-Systems for a government agency. Jack Lavers was the program manager.

The AN/UYK-23 was also used aboard the Lockheed U2 airplane as a NASA weather system processor. This led to experimental use aboard the Lockheed SR-71 to control air flow into the jet engines during high altitude turns. For the Lockheed SR-71 application use we replaced the cadmium plated I/O connectors with nickel plated connectors - this was to avoid the possibility of titanium embrittlement should the cadmium cable connectors accidentally come in contact with aircraft skin during maintenance. I think that Quint Fabro was the Program Manager for these two Lockheed applications. [labenson]

We built a total of 85 of this computer type.

The UYK-23 processor was provided to UTL for another EW system flown

on the Army's Mohawk aircraft. All of the development work was done

at the UTL facility in Garland, TX and test flights out of Love Field,

Dallas. John Westergren - See the Quicklook section of Systems, Airborne.

![]()

4.7 RMF

Three Reconfigurable Module Family Aviation chassis units are shown on the genealogy chart used the an updated version of the UYK-20's MPC logic design packaged onto three 6" x 9" modules. The '500' label meant that the unit could execute at a 500 KIP rate. An IR&D project initiated as a Low Cost Processor (LCP)packaged the MPC onto a single 6"x9" module operating at a 200 KIP rate. This LCP was the basis for the AN/UYK-502 computer.

The RMF 400 [a 400 KIP machine] consisted of two chassis

- CPU with I/O control and one memory module plus the memory expansion

chassis. This unit used the basic MPC to emulate the SK-2070 [a

Singer Kerfott] machine that was being used aboard the B-52 and KC-135 airplanes.

Although we demonstrated the operational capability, we didn't win the

upgrade proposal. [lab]

![]()

4.8 AN/UYK-502

The

MPC logic from the RMF-200 was updated to build the AN/UYK-502 for Canadian

applications. The design team [Dan Holste, Bob Beljeski, and others

who were reporting to me at the time] transitioned the manufacturing

of this unit to a facility in Winnipeg. Ken Buechler was one of

the receiving engineers reporting to the plant manager, Glen Johnson.

[lab]

The

MPC logic from the RMF-200 was updated to build the AN/UYK-502 for Canadian

applications. The design team [Dan Holste, Bob Beljeski, and others

who were reporting to me at the time] transitioned the manufacturing

of this unit to a facility in Winnipeg. Ken Buechler was one of

the receiving engineers reporting to the plant manager, Glen Johnson.

[lab]

AN/UYK-502(V), a 16 bit general purpose minicomputer was the

Canadian developed variant of the AN/UYK-20 which had a 64K of core

memory. Micro Programmed Controller (MPC) logic from the UYK-20 was

repackaged onto a set of 6" x 9" modules for the UYK-502. The Canadian

variant was built by Sperry Univac in Winnipeg around 1979-80. This

computer became the RCN's standard computer for use in many applications

and was also the standard computer for the SHINPADS and ADLIPS systems.

It was commonly found in Message Handling Systems. [Photo courtesy RCN]"

Thanks to Jerry Proc for the photo of the 502 shown here on the right.

[lab]

By Jerry Proc.: Based on my research I have the AN/UYK-502 as being

used in the RCN's ship borne Message Handling System, ADLIPS and SHINPADS

-http://www.jproc.ca/rrp/rrp2/1980s_adlips_link.html

and

http://www.jproc.ca/rrp/rrp2/1980s_teletype.html which outlines

ships teletype equipment from the mid 80's. Just so you know where

I fit into all of this. During the early 1990's I restored all

the radio rooms aboard HMCS HAIDA, a WWII Tribal class destroyer formerly

berthed in Toronto. The project took about 5 years working at home and

at the ship in my spare time. Invariably there was a necessity to document

all the small historical and technical details I was discovering. After

publishing my information in a limited edition, soft covered book, it

posted it to the web in 1997 and I have been building on it ever since.

It has undergone several name changes as more information was added.

It is currently titled Radio Communications and Signals Intelligence

in the Royal Canadian Navy. Currently it contains 1,600 files and is

60 MB in size and documents RCN radio communications from WWI to present

- http://www.jproc.ca/rrp/index.html.

I spent 16 years of my working life in the mainframe maintenance business

[DEC 8/10/11] and now I'm in network support. Writing about historical

electronics has now become one of my passions. What you see is a labor

of love fueled by an electronics background, curiosity and a need to

preserve technical history.

From Bruce Grewenow:

Hello Lowell and Keith: I was browsing thru

the website as I often do and did not see any info on the

AN/UYK-502. I have

totally lost track of the end result of the 502 designed for

Canadian Navy Shinpads project. I was the PM and Doug Hair was the PE. We worked with Glen (Easy) Johnson in Winnipeg.

I left the project some time before it was complete and have

a memory lapse as to the end result.

I also vaguely remember it was used in a Turkish portable

radar system? I travelled to Winnipeg so often that the hotel always put me up in a

spacious suite # 502. I also had to bring back some special Cuban cigars the could

not be bought in the USA. The customs guys would wave me thru even though I did not

hide the cigars.

What a great job you guys are doing. THANKS FOR THE MEMORIES

Bruce G.

Bruce: If you go to the home page, on the right side you'll see a 'Google search box'. Type AN/UYK-502 then click the magnifying glass thereby -

This search function will provide you with eleven links to pages that mention that computer.

Also, look at page http://vipclubmn.org/Canada.html.

I think that the hotel in Winnipeg was the 'Golden Oak'. Eventually some of the UYK-502s were replaced with UYK-505s -

Now, most of the UYK-505s have been replaced with Q-70 integrated display/processors.

Cheers!

Lowell A. Benson; BEE 1966, U of MN -

Retired, UNIVAC 1960 to UNISYS 1994 and U of MN 1994 to 2001

Life is the time, space continuum of human interactions!

4.9 AN/UYK-505

Not shown on the genealogy charts is the AN/UYK-505 configured for

the Canadian services. It had 128k of memory versus the original

AN/UYK-502 design

of 64k of memory. Refer to Gene McCarthy's

Career Summary for the background

information about these units. The first program to use the UYK-505

was the ADLIPS program where they purchased the First Expanded Memory

UYK-20s [16 Computers]. This was an upgrade to the four latest Destroyer

class ships, circa 1979. Of course the UYK-505 was then used on the sixteen

CPF Halifax Class Frigates as the SHINPADS Processors. Thanks

to Jerry Proc from Canada for pointing out that we'd missed the UYK-505

on our chart. Several UYK-20 look alike units were built for non-US

Navy applications, labeled the U1600.

![]()

4.10 LAMPS

This was a variation prepared for a Helicopter ASW mission. I believe that IBM won the computers for this system. [lab]

4.11 1817

This was ... {Editor's note: I don't know anything about this unit, can anyone help?}

4.12 AN/AYK-14

The US NAVY specified this 16 bit ISA for the AN/AYK-14 airborne

computer. Control Data Corporation did the development of the unit.

UNISYS competed for and won the second source award for producing this

standard Navy product. Tom Hansen was the marketing manager for the

2nd source proposal; Lowell Benson and Cliff Sheets led the proposal

team. [lab]

4.13 AN/UYK-44

This same Navy 16-bit ISA architecture was specified for the AN/UYK-44

next generation replacement of the UYK-20. The Navy specifications required

use of 'Standard Electronic Modules' (SEM) for logic implementation.

The SEM was subject to the Navy's Standard Hardware And Reliability

Program (SHARP) requirements, a pre-cursor to today's common ISO 9001

production quality requirements.

This same Navy 16-bit ISA architecture was specified for the AN/UYK-44

next generation replacement of the UYK-20. The Navy specifications required

use of 'Standard Electronic Modules' (SEM) for logic implementation.

The SEM was subject to the Navy's Standard Hardware And Reliability

Program (SHARP) requirements, a pre-cursor to today's common ISO 9001

production quality requirements.

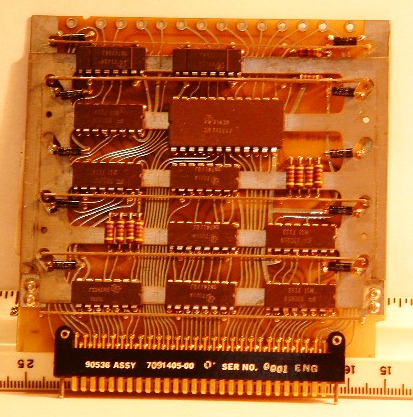

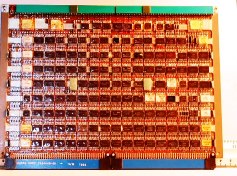

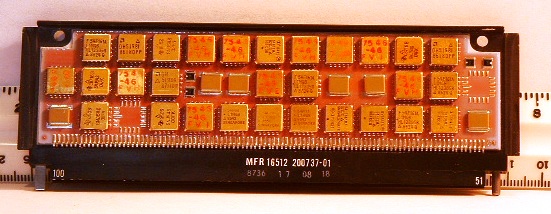

The functional density of the SHARP

module catalog was quite low with limited functionality. For

example a SEM B module would only hold six to nine Dual-In-Line packages

as shown on the left. Our engineering proposal team chose to use a size

SEM B format, using two sided surface mount integrated circuits, and

ceramic substrates for interconnect and cooling efficiency. This

innovative packaging approach illustrated by the module photo at the

right was one of the key factors in winning the UYK-44 development over

IBM. One other innovation implemented in the UYK-44 was a maintenance

processor; a Commercial Off The Shelf microprocessor chip and adjacent

control logic to do a designed in self test and semi-automated diagnostics

of the main processor logic. Such a maintenance processor concept grew

out of an Internal Research and Development project led by Lowell Benson.

This maintenance processor feature was also used for a couple of our

AF airborne computers, the AN/UYK-43, and the Memory Processor computer

upgrade for the CP-890. [lab]

The functional density of the SHARP

module catalog was quite low with limited functionality. For

example a SEM B module would only hold six to nine Dual-In-Line packages

as shown on the left. Our engineering proposal team chose to use a size

SEM B format, using two sided surface mount integrated circuits, and

ceramic substrates for interconnect and cooling efficiency. This

innovative packaging approach illustrated by the module photo at the

right was one of the key factors in winning the UYK-44 development over

IBM. One other innovation implemented in the UYK-44 was a maintenance

processor; a Commercial Off The Shelf microprocessor chip and adjacent

control logic to do a designed in self test and semi-automated diagnostics

of the main processor logic. Such a maintenance processor concept grew

out of an Internal Research and Development project led by Lowell Benson.

This maintenance processor feature was also used for a couple of our

AF airborne computers, the AN/UYK-43, and the Memory Processor computer

upgrade for the CP-890. [lab]

The AN/UYK-44 engineering development team is shown here,

photo

from Lee Holck via Jeff Parker.

Left to right these are: John Staubus, Jim Howe, Dean VanDeWalker,

Dan Holste, How Ho, Mike Bates, Al Riebe, Bob Oxbourough, Paul Burley,

Brian Nelson, Richard Shih, Bruce Hanson, Don Mager, Doug Hair, Leo

Schlecta, Don Pawlicki, Bill Poblete, Jeff Parker, Gary Nolting, Bob

Ebright, Craig Neudahl, Dave Senechal, Dave Watterson, Bob Caauwe, Ms.

Mary LaLone, Chuck Wenz, and Joe Juneau. Photo recognition credits to

Lowell Benson, Larry Bolton, Char Stockman, Bob Caauwe, Larry McCormick,

and Steve Wedger. [lab]

4.14 The U1834

This was a custom packaging and module integration IR&D project. We took the AN/UYK-44 thirteen SEM-B CPU module set, packaged these into a 6"x9"x3" carrier. We put this carrier into a full ATR chassis, added a 6"x9" CPU cache memory module, added the UYK-502 CPU module as an I/O processor, used two 32k core memory modules resulting in an airborne UYK-44 that could perform benchmarks at quadruple the speed of CDC's 4-year old AN/AYK-14.

We presented this 'double processor' approach to Lockheed and the

Navy at a sales meeting in the Skunk Works. I'm not sure who told whom

what, BUT, about 9 months later CDC got an AYK-14 enhancement development

contract which had a double processor architecture that was amazingly

similar to what we'd demonstrated in our laboratory! John Porter did

the cache memory and memory interface designs for this 'one-of-a-kind'

unit. Hugh Gallagher did the mechanical designs. [lab]

![]()

4.15 AN/UYK-507

from Gary Isliefson; ex-Sperry/Unisys/Paramax/Loral/Lockheed employee.

I worked at the Winnipeg Sperry site as a hardware

design engineer from 1983 to its eventual closure in the late 1990's.

I worked on AN/UYK-502, SHINPADs, and in the end the AN/UYK-507:

The AN/UYK-507 was the last development in the line of 16 bit

computers, being developed in the early 1990's. The AN/UYK-507 re-used

the AN/UYK-502's chassis and power supplies and adopted its 6x9 inch

circuit card format. Other than a modified maintenance panel, the AN/UYK-507

looks very similar to the AN/UYK-502, but inside it was state of the

art technology.

Its design consisted of three state-of-the-art CMOS (Complementary

Metal Oxide Silicon) custom ASICs (Application Specific Integrated Circuits)

which took the performance up to 50Mhz or approximately 50 Million Instructions

per Second (MIPS). The chips were fabricated by Motorola using their

state-of-the-art 1.0 micron fabrication center then producing the MC68040

(which only operated to 25Mhz to 33Mhz at the time). The architecture

of the chipset was a highly integrated superset of the AN/UYK-44, adding

a 5 level pipeline, cache memory, and hardware floating point math support.

Cache coherency was maintained in hardware also.

The three chips were designed in St Paul plant 8 headed by Brian

Leininger and Don Fier, with design leads Paul Torgeson, Kevin Leclair,

Duane Breid, Frank Dropps, and Winnipeg designers Ron Isliefson, Carl

Swanson, Martin Andruziak to name a few. A fourth ASIC was designed

in the Winnipeg facility which housed the I/O processing and memory

support logic, essentially marrying up the AN/UYK-502's RMF-based I/O

cards to the chipset's internal "common bus". It was designed by two

Winnipeg engineers, Kent Wotherspoon and Morgan Smail.

The design approach used in developing the chipset was also revolutionary

and worthy of mention here. At a time when other companies were still

designing chips with schematics, the AN/UYK-507 was entirely designed

and simulated using a Hardware Descriptive Language (HDL) known as "Ulysses".

Ulysses was developed by in-house engineers and allowed engineers to

quickly enter designs with a text editor and then simulate them with

Ulysses' time-less simulator on a common desktop PC or workstation for

larger simulations. In fact, the entire computer was eventually simulated

in Ulysses including I/O, running actual test software enabling first

pass success on the chipsets. Credit for Ulysses HDL and simulator goes

to Duane Breid.

Using an HDL for design entry and a time-less simulator are today

considered de-facto design practices, Sperry/Unisys was certainly ahead

of industry in this regard at that time.

It is believed about 1,800 AN/UYK-507's were deployed by the Canadian Navy in their Frigate program. Thanks, and I hope I didn't spell any names wrong!

5. Repertoire Cards

Many people gave repertoire cards to the Legacy Committee. Keith Myhre scanned the cards before they were donated to the Charles Babbage Institute. The 16-bit cards are linked hereunder. There are copies of many of these cards at the Lawshe Memorial Museum.

- AN/UYK-20 Computer Repertoire of Instructions

- AN/UYK-20/20A Technical Summary - NESEA

- AN/UYK-20/20A Technical Summary - NAVSEA

- PARAMAX AN/UYK-44 CPU Repertoire

- SPERRY AN_UYK-44 CPU Repertoire

- SPERRY AN/UYK-44 CPU Repertoire

- SPERRY AN/UYK-44(v) Data Processing Set - Reference Guide

- SPERRY UNIVAC 1616 & AN/UYK-15 Computer Repertoire of Instructions

- SPERRY UNIVAC AN/UYK-20 & AN/UYK-20A Computer Repertoire of Instructions

- SPERRY UNIVAC AN/UYK-20 Computer Repertoire of Instructions

- SPERRY UNIVAC AN/UYK-502 Repertoire of Instructions

- SPERRY UNIVAC Defense Systems AN/UYK-20 Computer Repertoire of Instructions

- SPERRY UNIVAC U1600 & U1600EM Computer Repertoire of Instructions

- SPERRY UNIVAC U1600 Computer Repertoire of Instructions

- SPERRY UNIVAC Defense Systems U1600 Computer Repertoire of Instructions

- UNISYS AN/UYK-44 CPU REPERTOIRE

- 16-Bit Instruction Repertoire

6. Technical Manuals

The bit-savers web site (http://bitsavers.informatik.uni-stuttgart.de/) has over 32,000 documents. We've copied the 16-bit ISA documents and linked them hereunder for technology researchers ease of access.

- PX6477C UNIVAC 1616 General Description

- PX7917 Sperry Univac AN/UYK-15 Technical Description

- SB10160 Product Function Specification - Data Processing Set AN/UYK-20 (V) and AN/UYK-20X(V)

- Sperry Univac AN/UYK-20 Technical Description

- UNIVAC 1616 I/O Description.- March 1972.

In this Chapter

- Introduction [left]

- User feedback

- Computer Family [left]

- Genealogy

- 16 bit model descriptions:

1616, AN/UYK-15, MPC16, 3760, AN/UYK-20, AN/UYK-23 (1816), LAMPS, (RMF500*, 200), AN/UYK-502, AN/AYK-14 2nd Source, AN/UYK-505, 1834, AN/UYK-44, and the AN/UYK-507 - Repertoire Cards

- Technical Manuals

Chapter 54 edited 7/13/2025.